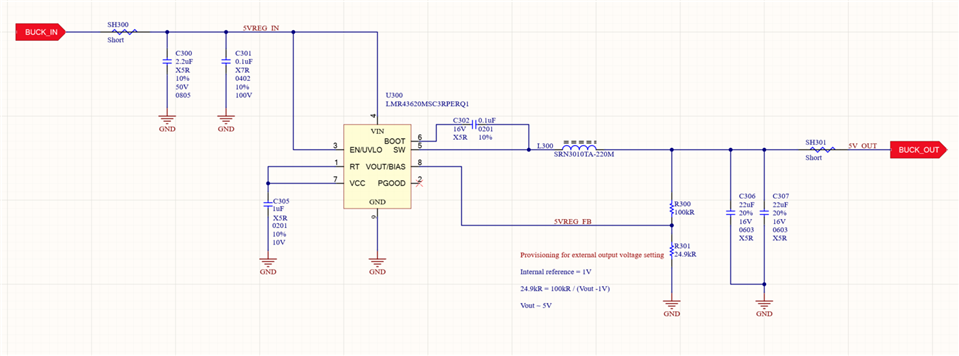

Above is a photo of our application. When SH300 & SH301 are cut to externally power input and load via eload at output for efficiency measurements, we are not seeing the efficiency that is reported in the spreadsheet that was provided to us during design phase by TI (Datasheet only had efficiency data for Vout = 3.3V). The spreadsheet showed efficiency in the 90s. Note that we did try multiple types of 4.7uH for L300, but efficiency results did not improve. We are seeing somewhere around efficiency 50-60% with Vin is 10-12V (Vout = 5V). Attaching sheet below. Please provide us guidance on why we are seeing this difference and/or suggestions on how to improve.