Other Parts Discussed in Thread: SN65HVD1781, TPS2491, CSD19537Q3, TPS62091, LMR16030, ,

Hi.

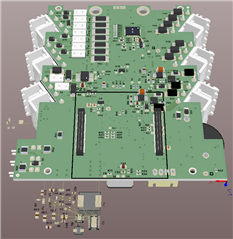

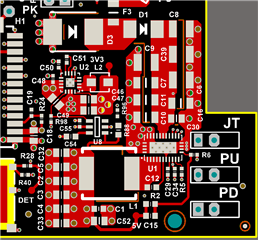

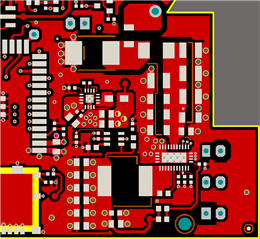

We are developing a board layout which already has these parts from TI:

1x SN65HVD1781

2x TPS2491

2x transistor CSD19537Q3

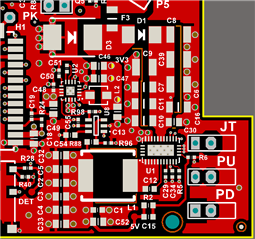

The board will be supplied by industrial power supplies, 24V nominal. Before, the buck converter was a LMR16030 with 3.3V output, but I changed it by a LM76005 because we will try to add compatibility with Raspberry Pi Compute Module 3 and 4 to it, so I needed to change the main power supply output to 5V using LM76005, because it has more output current capacity, then I'm going to reduce that 5V to 3V3 by using a TPS62091. I need 5V and 3V3 in my circuit.

Please, could I receive an analysis from TI engineers in my schematics and calculations?

(1) About the TPS62091, here is the Webench design, the inductor I chose is exactly the one suggested on the Webench design.

(2) Here are the calculations I did for LM76005 (5V output) until now. OBS: The fact is that in practice, this 5V output will never reach 4A average current consumption.

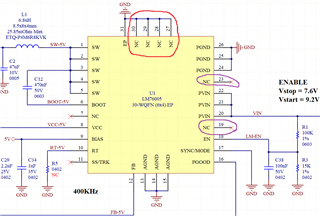

LM76005, Vout of 5V x 5A, Vin of 10 to 40V, 400KHz

------------------------------------

FEEDBACK RESISTORS

------------------------------------

Vin = 10~40V

Vout = 5V

Iout = 5A

Vfb = 1.006V

Resistors = 100K/24.9K

Vout Typ = 1.006+1.006*(100/24.9) = 5.04V

Vout Max = 1.017+1.017*((100*1.01)/(24.9*0.99)) = 5.18V

Vout Min = 0.987+0.987*((100*0.99)/(24.9*1.01)) = 4.87V

------------------------------------

SOFT-START CAPACITOR

------------------------------------

Pin SS/TRK left floating.

Leave this pin floating to use the 6.3ms internal soft-start ramp

------------------------------------

UVLO/ENABLE

------------------------------------

Connections: VIN - RenT - ENABLE - RenB - GND

RenB = (VEN_VOUT_H * RenT) / (VIN_ON_H - VEN_VOUT_H)

VEN_VOUT_H Typ = 1.204V

VIN_ON_H = 9.2V

RenT = 100K 0603 1%

RenB = (1.204 * (100)) / (9.2 - 1.204)

RenB = 15.05K

RenB = 15K 0402 1%

VIN-UVLO-RISING = VENH * (RENB + RENT) / RENB

VIN-UVLO-RISING = 1.204 * (15 + 100) / 15

VIN-UVLO-RISING = 9.23V

VIN-UVLO-FALLING = VENL × (RENB + RENT) / RENB

VIN-UVLO-FALLING = 0.99 * (15 + 100) / 15

VIN-UVLO-FALLING = 7.6V

------------------------------------

SWITCHING FREQUENCY

------------------------------------

RT pin. If floating, the default switching frequency is 400 kHz.

Place a resistor in the layout but do not mount it, at RT pin.

------------------------------------

DUTY

------------------------------------

Dmin = tON-min * fsw

Dmin = (70*10^-9) * (400*10^3)

Dmin = 0.028 (2.8%)

Dmax = 1 - (tOFF-min * fsw)

Dmax = 1 - ( (100*10^-9) * (400*10^3) )

Dmax = 0.96 (96%)

Vin Max and Vin Min.

The maximum operational supply voltage can be found by:

VinMax = Vout / (fsw * tON-min)

VinMax = 5 / ( (400*10^3) * (70*10^-9) )

VinMax = 178V

The minimum VIN without frequency foldback can be approximated by:

VinMin = Vout / (fsw * tOFF-min)

VinMin = 5 / ( (400*10^3) * (100*10^-9) )

VinMin = 125V

------------------------------------

INDUCTOR SELECTION EQUATIONS

------------------------------------

deltaIL = ( (Vin - Vout) * D ) / (L * fsw)

L >= ( (Vin-Vout) * D ) / (0.4 * fsw * I-load-max)

L<= ( (Vin-Vout) * D ) / (0.2 * fsw * I-load-max)

Inductor saturation-current rating.

ILpeak = I-load-max + (deltaIL / 2)

D ~= Vout / Vin

------------------------------------

INDUCTOR SELECTION CALCULATIONS

------------------------------------

Vin = 40V

Vout = 5V

D ~= 5/40

L >= ( (Vin-Vout) * D ) / (0.4 * fsw * I-load-max)

L >= ( (40-5) * 5/40 ) / (0.4 * (400*10^-3) * 5)

L >= 5.46uH

L<= ( (40-5) * 5/40 ) / (0.2 * (400*10^-3) * 5)

L<= 10.93uH

L range = 5.46uH to 10.93uH

* On the tag of the product will be specified a voltage supply range from 12V to 38V.

* On great majority of the cases the supply input will be 24V, from a industrial power supply.

* In history, we have seen only few industrial power supplies, of old machinery, delivering 36V at the maximum.

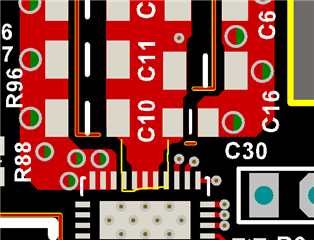

* Chosen inductor = IHLP3232DZER6R8M11 (Vishay):

- 6.8uH +- 20% (6.8uH * 0.8 = 5.44uH)

- Irating = 7A, Isat = 6.7A

- DCR = 33.4mOhm max

deltaIL = ( (Vin - Vout) * D ) / (L * fsw)

deltaIL = ( (40 - 5) * 0.125 ) / ( (6.8*10^-6) * (400*10^3) )

deltaIL = 1.6A

ILpeak = I-load-max + (deltaIL / 2)

ILpeak = 5 + (1.6 / 2)

ILpeak = 5.8A

------------------------------------

FEEDFORWARD CAPACITOR

------------------------------------

FX = 15.46 / (Vout * Cout)

FX = 15.46 / ( 5 * 6 * (47*10^-6) )

FX = 10.964 KHz

CFF = ( 1 / (2*pi*FX) ) * ( 1 / ( sqrt ( RFBT * (RFBT // RFBB ) ) ) )

CFF = ( 1 / (2*pi*FX) ) * ( 1 / sqrt ( RFBT * (RFBT * RFBB / (RFBT + RFBB) ) ) )

CFF = ( 1 / (2*pi*10.964*10^3) ) * ( 1 / sqrt ( 100000 * (100000 * 24900 / (100000 + 24900) ) ) )

CFF = 3.25 * 10^-10

CFF = 325pF

CFF = 330pF

For the current 6.8uH inductor, I don't wanted to use a bigger physical size inductor (with bigger area), because space is so much 'at a premium'.

Suggestions and recommendations from TI engineers?

Regards.