Other Parts Discussed in Thread: EV2400, , BQSTUDIO, BQ28Z610, BQ34Z100

Hello TI,

I am using BQ28Z610EVM-532, EV2400 for evaluation and Battery pack is UB26650-7.2V-5000mAh

UB26650-7.2V-5000mAh battery pack have Inbuilt Short circuit protection circuit, pack have two 26650 cell which connected in series, have only 2 battery connection which is Pack+ and Pack-.

Battery Pack,

Nominal voltage- 7.4V

Charging voltage- 8.4V

Capacity- 5000mAh

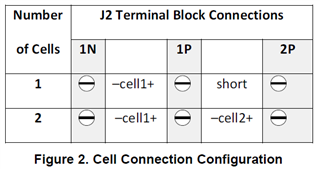

Made battery pack connection is 1S -

1. Pack+ connected to 2P (Shorted 2P & 1P)

2. Pack- connected to 1N (Shorted 2P & 1P)

1. BQ28Z610EVM-532 can support UB26650-7.2V-5000mAh battery pack..?

2.When release S1 from BQ28Z610EVM-532 then BQstudio is disconnected, In this case charger is not present.

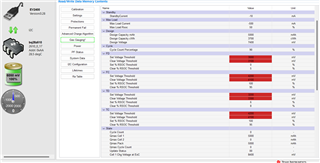

3. When charger and battery is present, then also it's release communication and reconnect again, what is issue and how i can remove ..?(I attach Data memory configuration UB26650.gg.csv )

3. Facing issue to Update FD, FC, TD, TC as per the battery pack, error message (Value is beyond maximum value defined for parameter)

We need help to configure BQ28z610 for my battery pack.

Thank,

Rahul