Hi,We have an abnormal case about LM5069 and need your assistance.

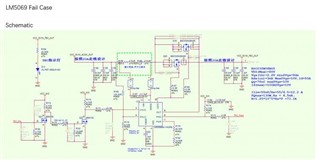

In our design, the LM5069 is used for overcurrent protection and the load is Thermo Electric Cooler(TEC). Here is our schematic.

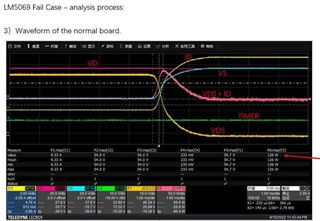

On a normal board, we enable LM5069 by UVLO. The MOS startup waveform is as follows: It can be seen that during the opening process, the maximum power on MOS is about 126W.

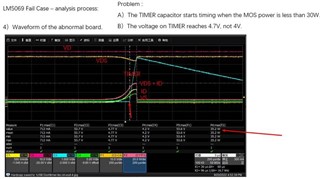

Recently, we found some abnormal boards, and the LM5069 on these boards cannot be started normally. Specifically, when the power of MOS opening process reaches about 30W, the TIMER capacitor of LM5069 will start abnormal timing, and when the timing time arrives, the chip output shut down just like following waveform.

These abnormal boards functioned well before they are put into use. The above anomaly occurred after about 1 month of use. We have tested and found no abnormal interference on the sampling resistance. We have 10 abnormal samples wiith similar abnormalities. After blowing the board with hot air device for ablout 1 minute, the abnormal phenomenon disappears. We tried to do the above treatment on three samples, and the results were consistent.

Then we put these 3 samples into the high and low temperature cycle and high humidity test box (5℃ - 75℃,95%). For the first sample, after 16H cycle, abnormal phenomena reappear, after baking at 80℃ for 80 minites,abnormal phenomena disappears. For the second sample, after 10H cycle,abnormal phenomena reappear, the timer capacitor starts timing when the MOS power is 30W,when it comes 39W, device turns off the MOS. After baking at baking at 80℃ for 10 minutes,the timer capacitor starts timing when the MOS power is 45.2W, when it comes 73W, devices turn off the MOS.

The above tests show that temperature and baking can change the phenomenon of the problem.

We reduce the input voltage of the abnormal board, and the corresponding abnormal protection power point becomes smaller.

We found similiar case on E2E website,we want to know how did the case turn out and how was it resolved? Do you have advice for our current case?

e2e.ti.com/.../lm5069-damaged-lm5069-devices-unable-to-control-inrush