- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

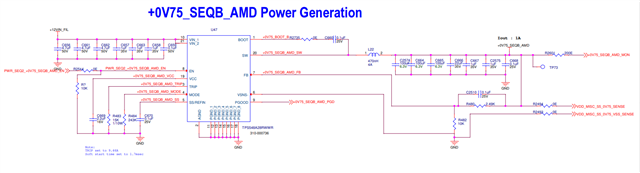

Currently, we are designing a buck converter using TPS548A28RWWR & TPS543A26RYSR this part number for our application.

We need your support to review the design, whether it looks ok?

We are having some queries and listed below,

please find the TPS548A28RWWR inputs below,

Vin -12V

Vout - 0.75V

Iout - 1A

Fsw - 800KHz

Mode - FCCM

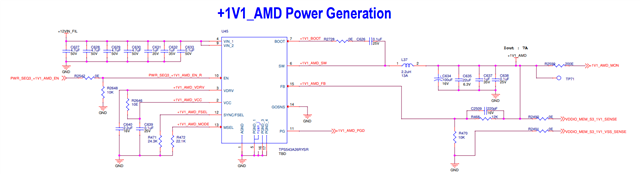

For TPS543A26RYSR Inputs,

Vin -12V

Vout - 1.1V

Iout - 7A

Fsw - 500KHz

Mode - FCCM

Thanks,

Dinesh

I believe using a 15A device at 1A output may be confusing algorithm. Let me check

calculation sheet was not attached.

0.75V

Do you really need differential remote sense for a 1A output current?

Are you open to using TPS54J061 for the 0.75V output.

C670 (ss cap )should connect to VSNS- near pin 6, if using the remote sense

R484 R483 should connect to an AGND

C669 should connect to PGND.

C2510 is very large.

AGND should connect to PGND at one location.

See 10-1 page 40 for pcb layout example.

See figure 8-1 page 25 of datasheet for schematic example of agnd and pgnd

www.ti.com/.../tps548a28.pdf

Typically, inductor ripple is 10% to 40% of Iout. The tools have a range min and max inductance for control.

When using 1A, which is

Why use the TPS543A26 when the TPS548A28 was used for the 0.75V

Use the TPS548A28 for the 1.1V/7A

The pcb layout can be reused from 0.75V.

Instead learning two devices, there is synergy when using one device for both sockets.

Purchasing volumes will be greater when using for both sockets. Inventory is easier.

1.1V

On the high current supply, it is not clear you are not using the remote sense. Drawing GOSNS to the Cout

see figure 8-1 in datasheet for schematic example

an L of 2.2uH the equation must be incorrect in calculation. Webench estimates 1.2uH.

Similar to webench I get 1.0uH using the equations in the datasheet.

Use 2x100uF Cout.

Similar feedback on Agnd and pgnd.

R471 and R472 connects to agnd

C639 connects to agnd

C640 connect to pgnd.

see figure 8-23 for pcb layout example