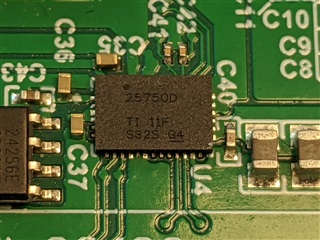

Other Parts Discussed in Thread: BQ25798, TPS25750EVM, TPS25750, BQ25792, BQ25731

Hello,

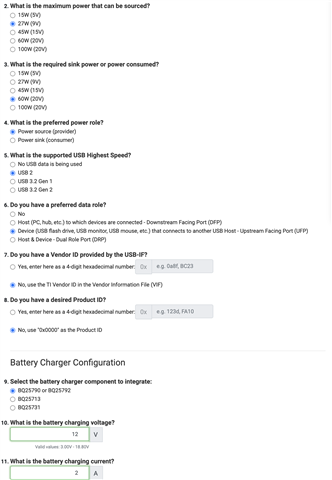

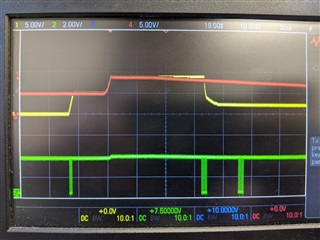

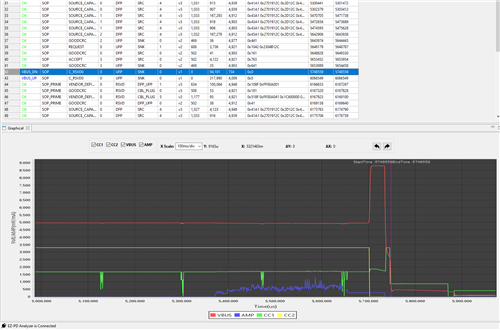

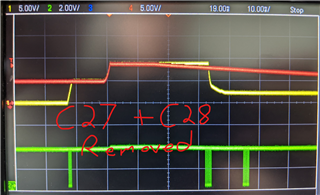

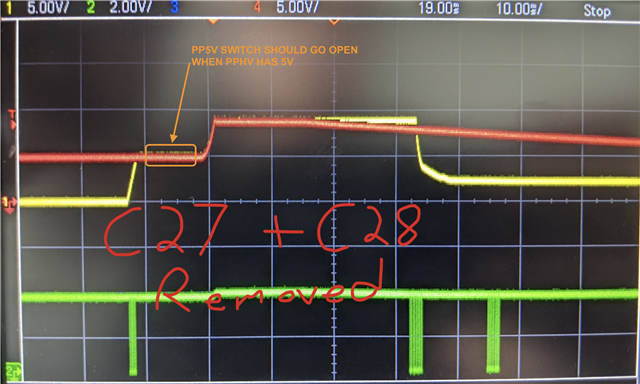

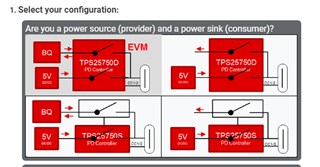

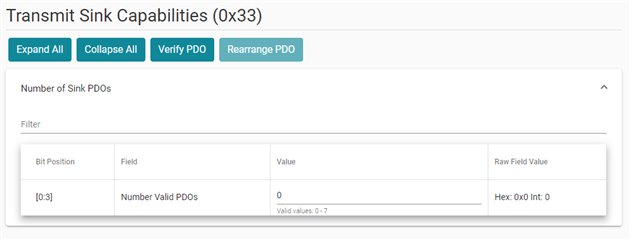

I just received the EVM and followed the instructions verbatim and cannot get the GUI output to generate >5V output. My issue is similar to that found in another thread and it certainly would be nice if the GUI was updated to actually generate a file that works.

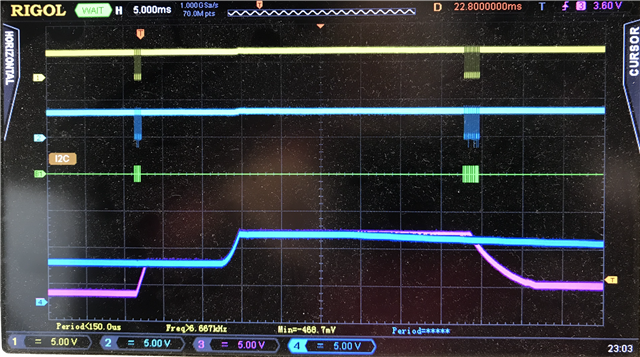

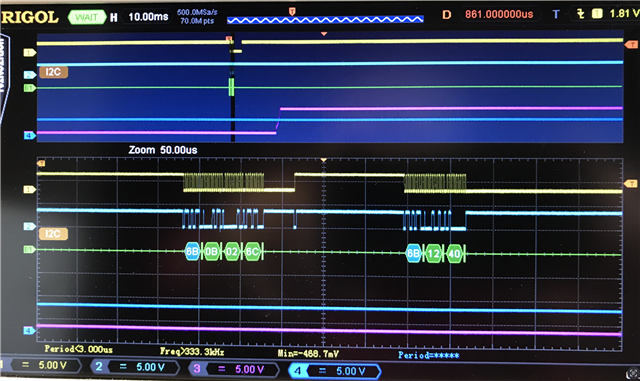

I see the very same behaviour as Nate did in that thread.

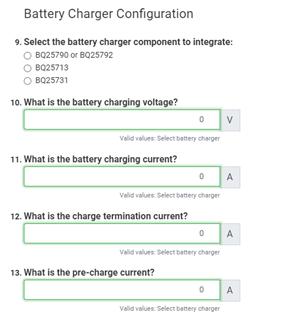

What I have gotten to work is a single PDO @5V, but any higher voltage output that makes use of the BQ25798 fails. Why does the GUI not have the BQ25798 listed as an option as shown in the video provided by TI?

I can provide configuration file so that someone could generate a working binary file.

Thanks,

Richard