Other Parts Discussed in Thread: TPS25750, , BQ25792, TPS54531, BQ25731, BQ25756, TPS25750EVM, BQ25798

Hi,

I am running into some roadblocks with the TPS25750 chip and want to confirm the behavior I am seeing is expected.

Our goal with this chip is to create a power bank device that only interfaces through USB C with a preferred power role of source, and minimum power profiles in both directions of 60W. Ie it must support all standard profiles between 5V/3A to 20V/3A (Ideally 100W as well)

- I have tried loading many configurations onto the USB-PD-CHG-EVM-01 with the following findings: Sinking profiles all the way up to 100W work, and the only sourcing profile that this chip is capable of is 5V/3A. Is this expected?

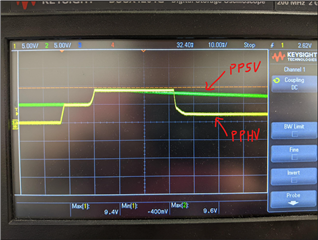

- When sourcing 5V/3A from the USB-PD-CHG-EVM-01 I would have expect the TPS25750 chip to request 5V from the BQ25792, but instead it seems to use a dedicated 5V buckboost that is also on the board. Is there any way to configure the TPS25750 to request the 5V from the BQ25792 and not the onboard TPS54531D? It seems excessive to have both of these chips.

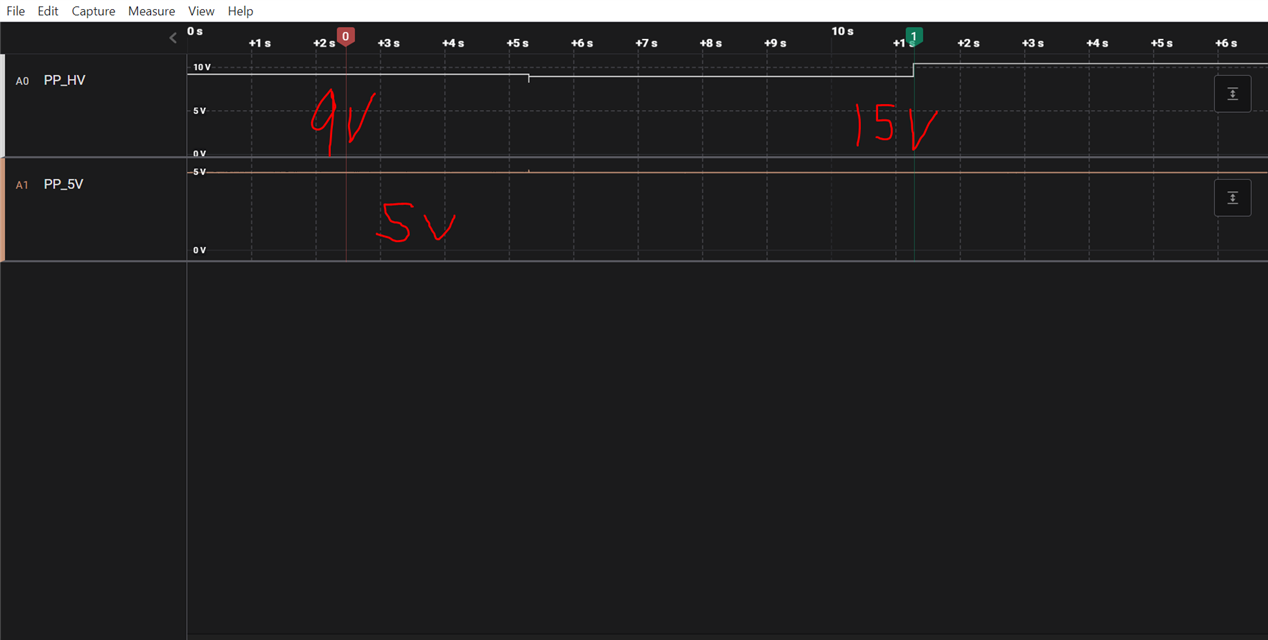

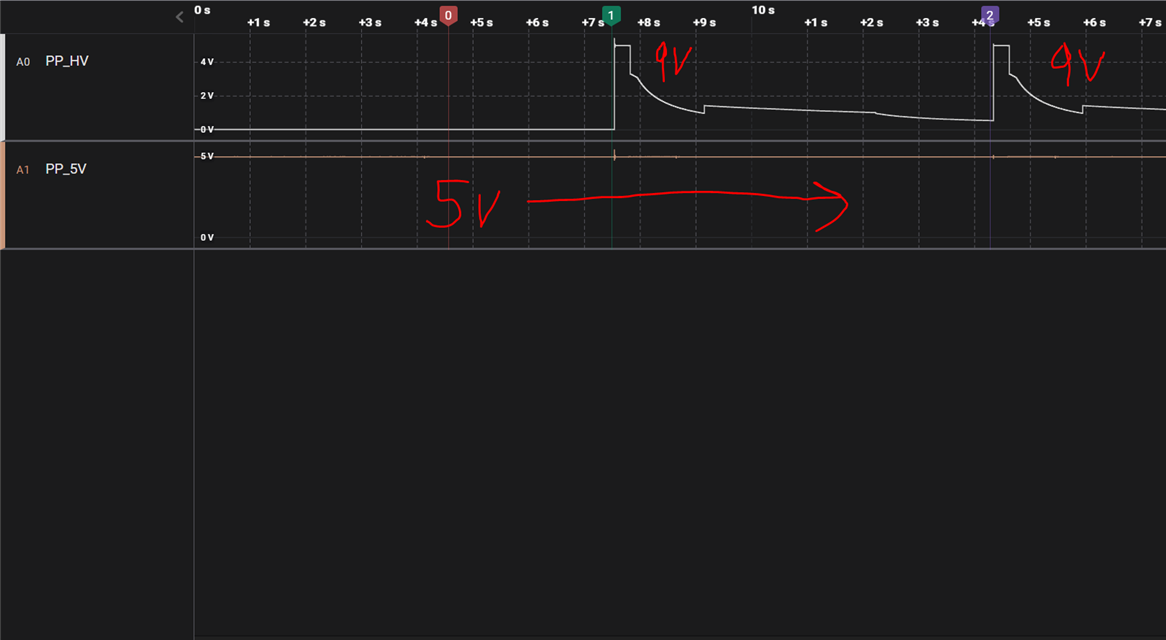

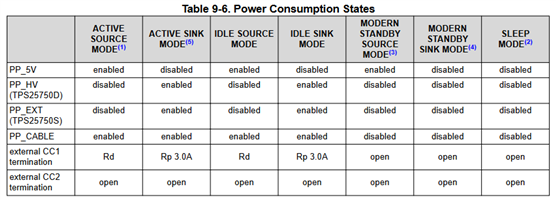

- Digging further into the documentation of this chip, the TPS25750D states that it has a "Integrated 28-V, 7-A, 16-mΩ bi-directional load switch", but in the rest of the documentation it does not seem as though it is capable of actually being "bidirectional". In table 9-6 on page 47 of the datasheet it says that while in active source mode, the PP_5V power path is the only one enabled. This seems to limit the sourcing capabilities of this device to a maximum of 5V unless you bypass the chip as has been done in the USB-PD-CHG-EVM-01 with the TPS54531. Can you confirm this is true? And would this limitation would be present for the TPS25750S and D variants?

- I have been digging through forum posts and documentation for using the USB-PD-CHG-EVM-01 as a higher power source and ran across this forum post: https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/1245968/usb-pd-chg-evm-01-connection-failure-with-tps25750evm. In it there is mention of a new chip that is supposed to come out in Q3 of this year. What is the current status of this chip?

- What is the TI's recommended architecture for a battery bank that can source and sink up to 60W (ideally 100W capable)?

Thanks,

Nate