Other Parts Discussed in Thread: BQ24192, , BQSTUDIO, GPCCHEM, BQ27531EVM

Hi,

first i would like to wish you all a happy new year 2024.

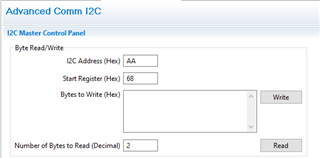

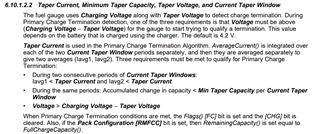

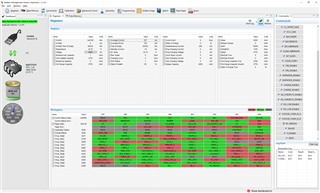

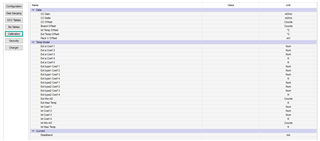

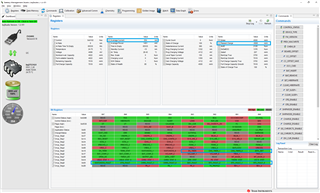

We use in our project the bq24192 together with the gauge bq27531 which control the charger. Due some new requirements resulted during the tests, i want to execute a new lerning cycle. How to start this with the current golden image? And how to set the Update Status register to 00, because this is required as per document "Achieving the successful Learning Cycle"?

Any suggestions are welcome.

Regards,

Alex