Hello,

Background:

Because of our application scenario, the battery is in Relax state for a long time, and the battery will be recharged only after the battery self-depletion (current <1mA) reaches a certain value.

FuelGaugeIC's Sleep mode has a current of 10mA. i.e. the process of battery self-depletion is not sensed by FuelgaugeIC.

Recharge interval:RM<278mAh to recharge; RM>318mAh to stop recharging and keep Relax.

Problem Description:

In order to verify that the Filtered FCC of the FuelGaugeIC can be correctly matched to a new battery during the aging process, we envisioned the following scenario.

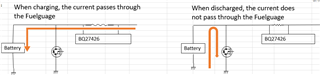

Charging is done through the FuelGaugeIC with a charge current of 390mA;

Discharge the battery without the FuelGaugeIC, using other circuits to discharge the battery.

Question:

1, Is this solution feasible and can Filtered FCC track the aging process of the battery?

2, When discharging a battery through other circuits, where the current does not pass through the FuelgaugeIC, and the FuelGaugeIC has access to the battery voltage, does the RM value change during or at the end of the discharge process? Will it match the battery voltage?

3、If it is not feasible, please advise why?

4、If it is feasible, is it necessary to add Relax time between charging stop and discharging stop? What is the specific time setting?

Best Regards.