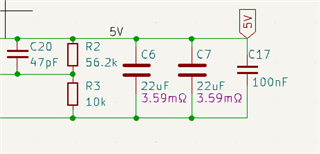

We are making a cost-effective power distribution board for our drone.

The board is supposed to supply :

-

20A at 17.4V to a 4in1 ESC (powering 4 BLDC motors) max.

-

5V to flight controller at 3A max.

-

12V to video transmission system at 1A max.

Components have been bought but before board manufacturing, requesting a review of the work. We have tried to follow layout guideline from the datasheet as much as possible.

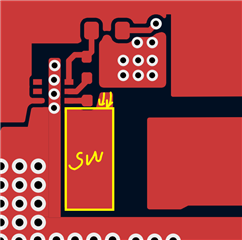

5V BUCK - 800kHZ

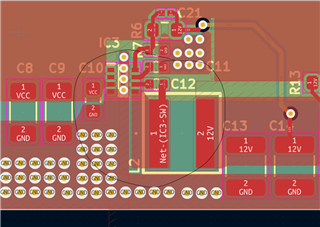

12V BUCK - 500KHZ

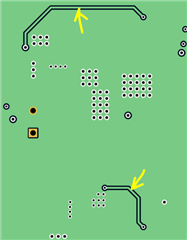

Files PDBV2-D01.pdf

Schematic

PCB individual layers

The mechanical dimensions of the board were decided beforehand, we are not allowed to make it any bigger or smaller.

Thanks in advance!