Hi

I designed board with TPS62932 and measured efficiency does not meet datasheet's efficiency.

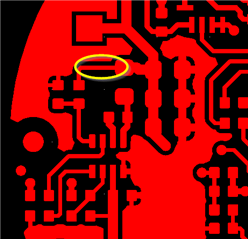

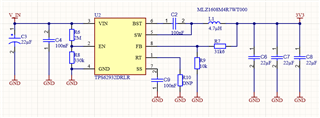

Schematic of tested board:

Power supply connected to V_IN

Programmable DC load connected to 3V3

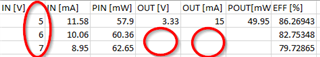

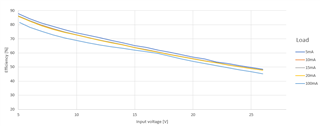

The results:

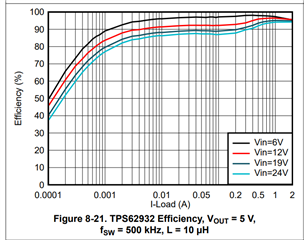

Datasheet efficiency:

So I expected to have efficiency at least 80% with load current above 10mA.

Do you have any idea why the efficiency is so low?

Best regards

Tomasz

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.