Hi,

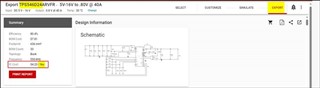

In the TI power designer, I have found that this tool can support four optimization orientations. I would like to know the methodology behind small footprint, low cost, balanced, and high-efficiency designs.

As far as I am aware, the small footprint design is based on a higher switching frequency, while the high-efficiency design is based on a lower switching frequency. For the low-cost design, is the target to only adopt low-cost components? Additionally, what is the method for achieving a balanced design?

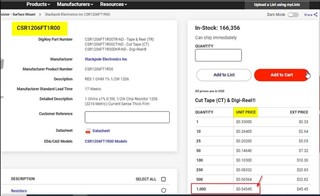

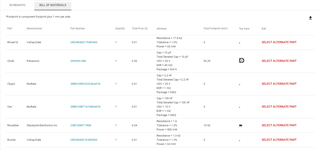

This tool also provides a BOM list, with each component having its price. Is the price based on purchasing a very high quantity? Or what’s the price based on?

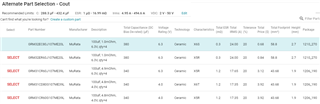

The alternative part selection lists various components of the same type. I believe there is a component library built into the website. Can these component libraries be shared with us, such as capacitors, inductors, resistors, MOSFETs, SPS, etc.?