Tool/software:

Dear TI Team,

Would you please let me know if the PSpice model has got corrected and updated?

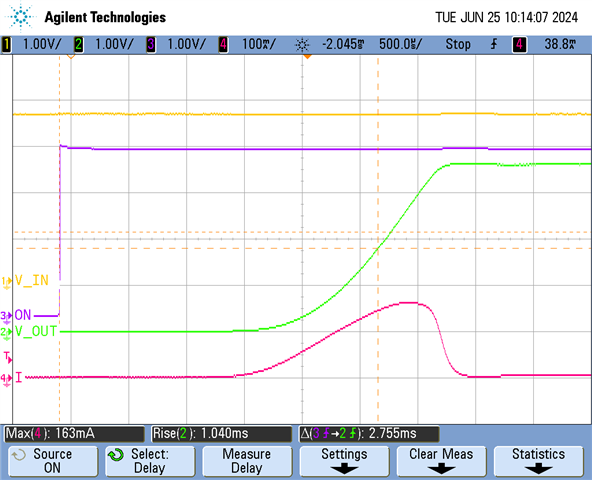

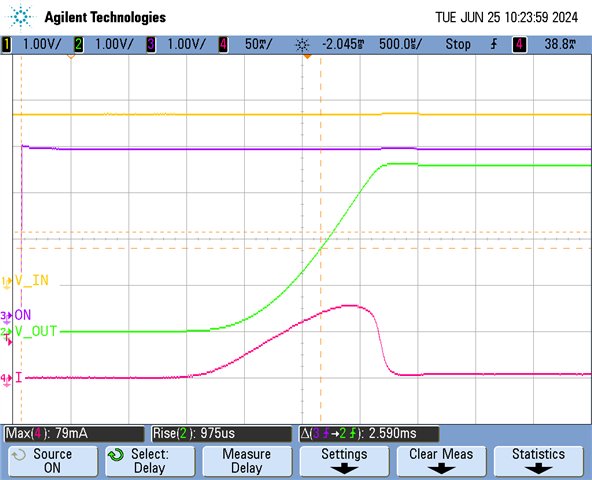

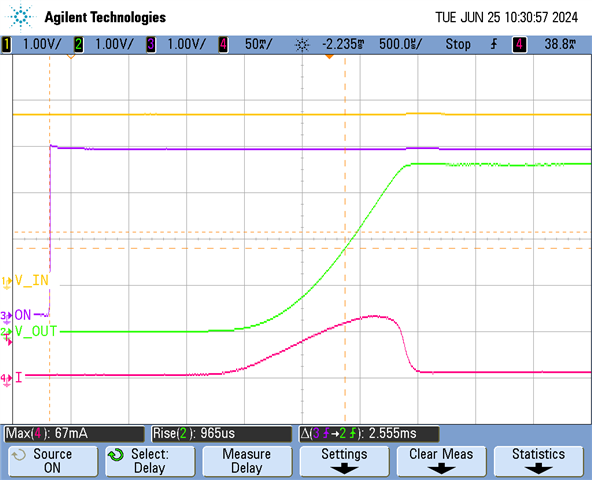

I tried to replicate figure 10-3 in the datasheet and simulate the circuit based on that (CT=1000pF, CL=47uF and RL=1K) but got the results far off from the datasheet.

I got 362mA inrush current instead of 150mA and 480us risetime instead of 1.037ms.

Besides that, Could you please let me know why the results in figure 10-3 do not concur with the formula?

Based on the formula 6 with CT=1000pF we should get 1.9 mv/us slew rate and then with the calculated slew rate and using formula 5 the inrush current should end up to 89.3mA(CL=47uF). Would you please let me know why it has been measured 142mA?

Best regards,

Amir