Tool/software:

Hi Mike,

Schematic is reviewed by you which was shared to you by Nihil.

Vin: 280VDC

Load : 26V regulated, 10A

Transformer primary inductance: 2mH

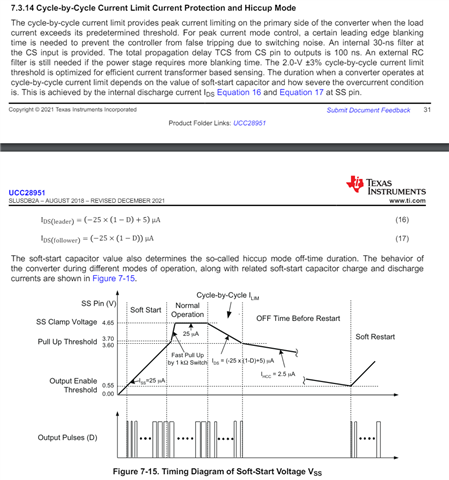

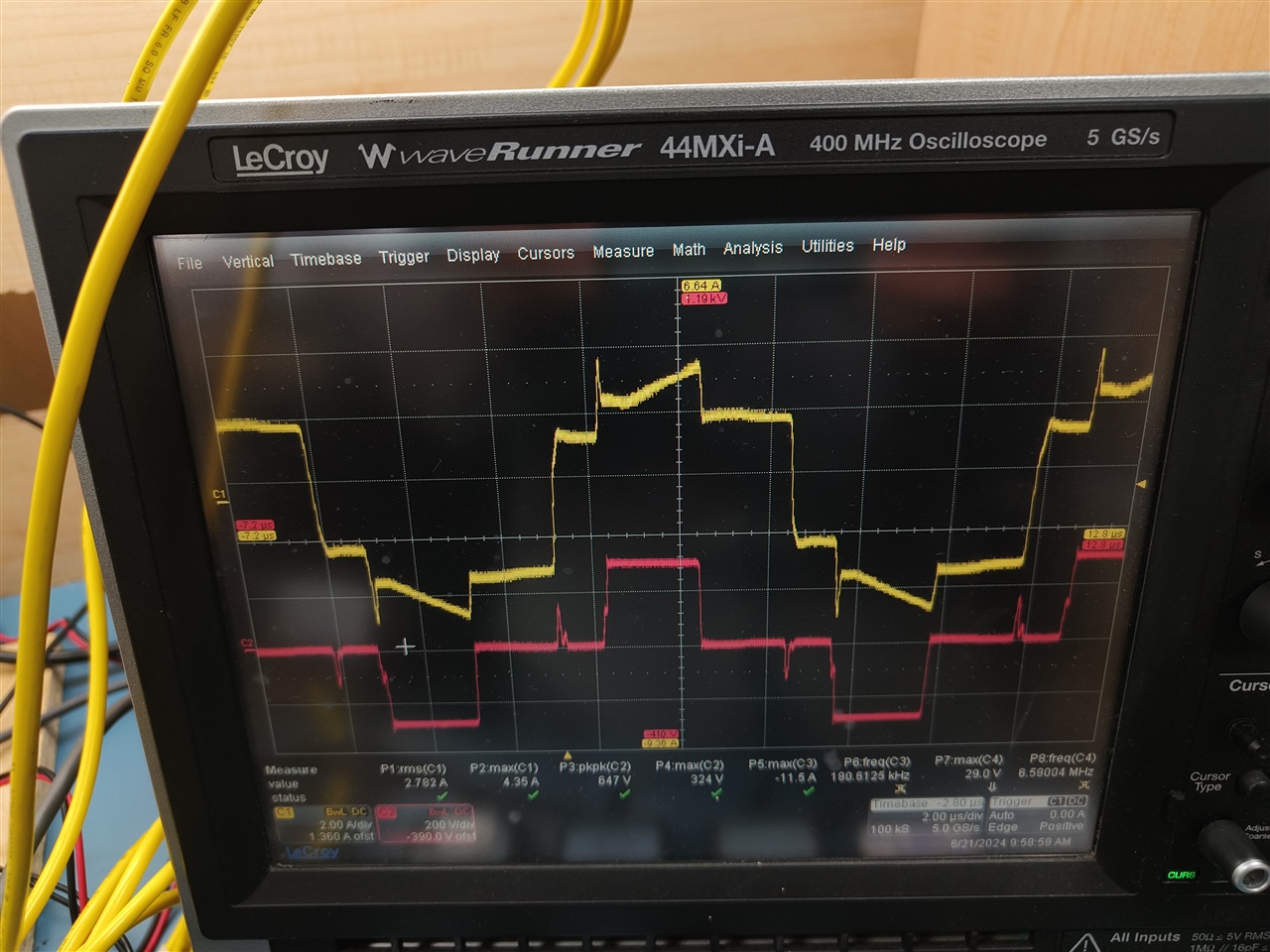

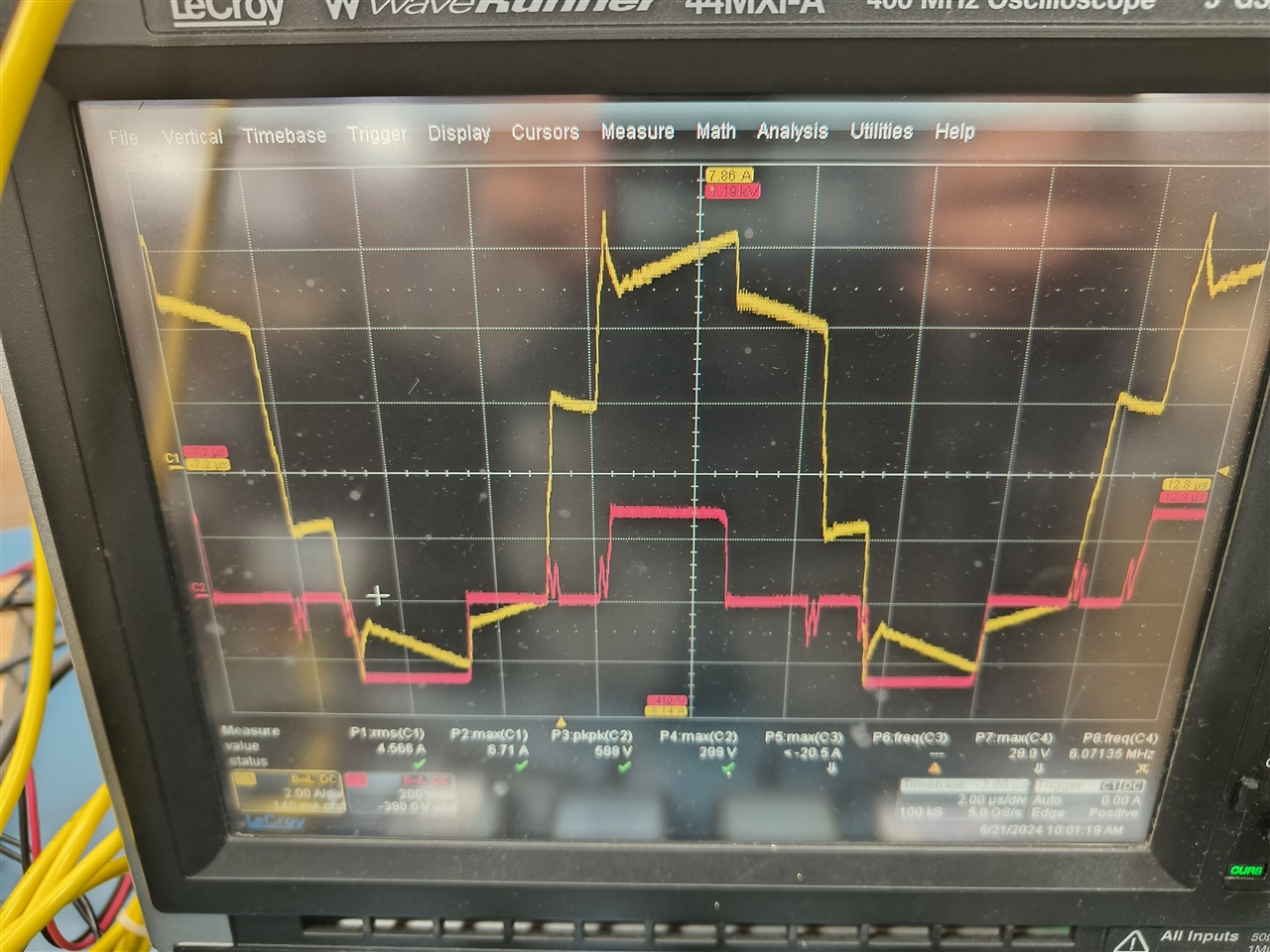

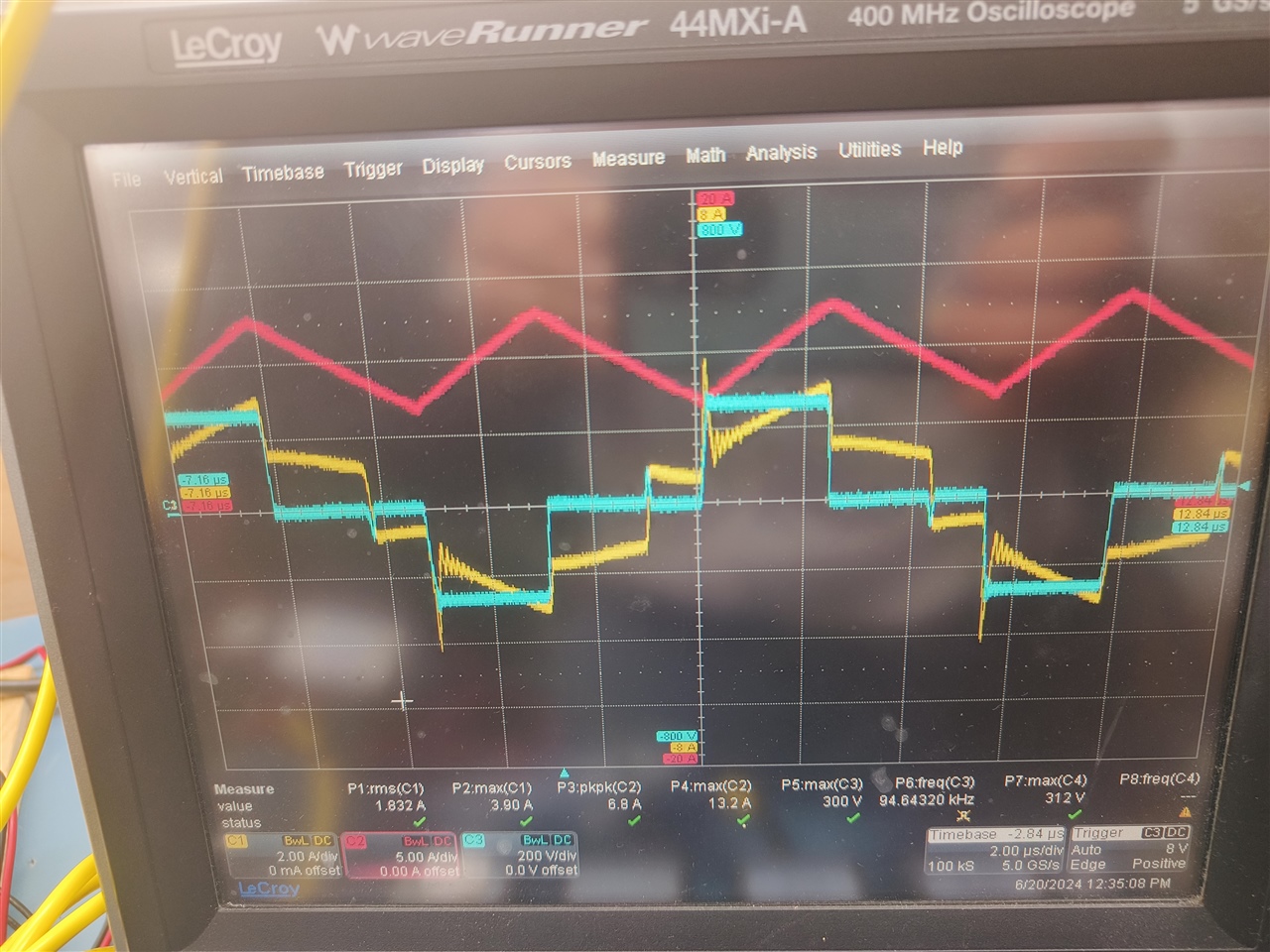

1. Below are the primary current waveforms,

Along with inductor current. Are they correct ? Why the initial peak in current?

Yellow: primary current

Red: inductor current

Blue: transformer primary

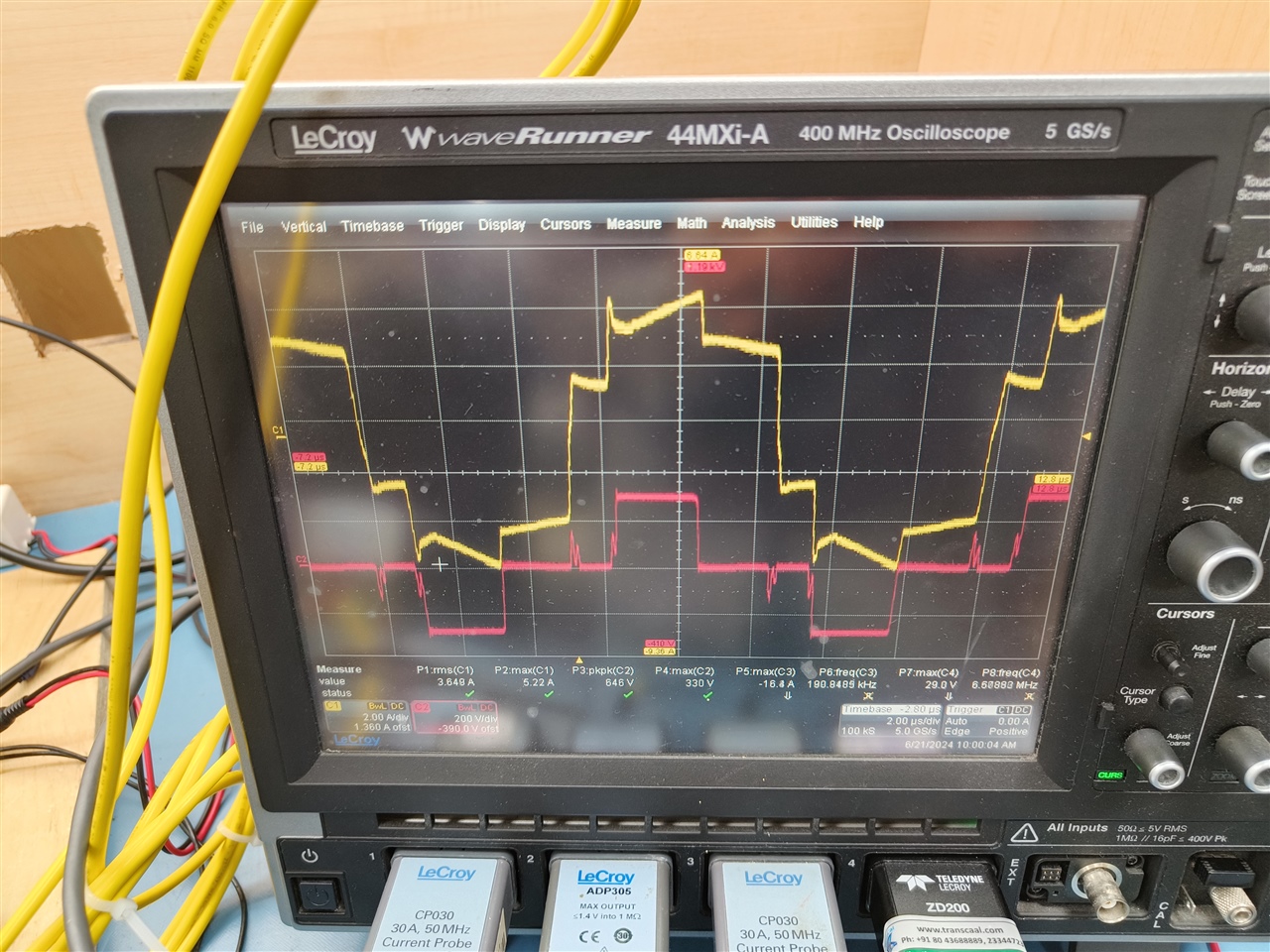

2. Output voltage waveform with ringing. The outputs are connected in series winding, regulated to 24V.

Blue: output voltage

Yellow: primary current

Green : primary gate B

Though compensation is still in progress, I tried adding higher SRF capacitors by measuring the ripple frequency ( 6 Mhz ) and also tried increasing output inductance, still that ringing didn't change. Inductor waveforms also looks clean from waveforms. Till it enters inductor I don't see any ringing.

That ringing increases with increase in load current.

One more thing which I noticed is bottom winding ( vout 2 ) didn't have ringing, only minor spikes. Tomo plan is to check both windings seperately and check whether interwinding capacitance at secondary is trouble or primary side transformer coupling capacitance is trouble ?

I WILL also check both winding seperately.

Compensation values @ present:

Cz:6.8nF

Rz: 51K

Cp: 680pF

Rsum : 91K

Your thoughts and advise ??