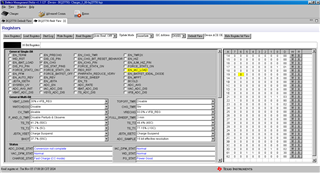

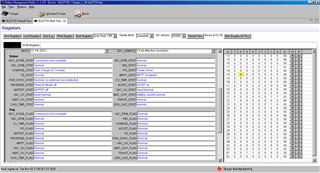

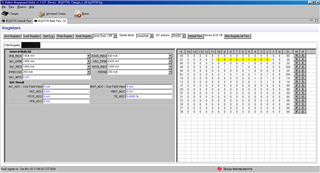

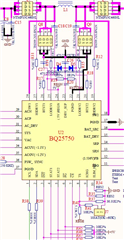

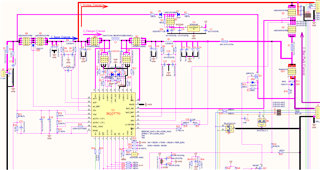

Other Parts Discussed in Thread: BQSTUDIO, BQ25758, EV2400

Tool/software:

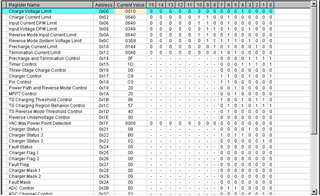

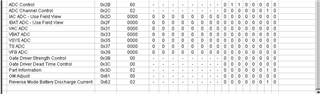

- Check EN_CHG=1

- Setup CE = low

After following these steps, I didn’t measure any charging voltage at the charging output (all other BQ25750 registers remain at their default settings).