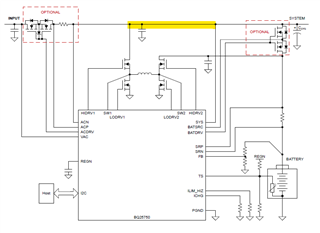

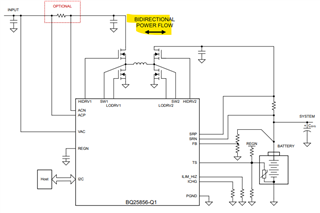

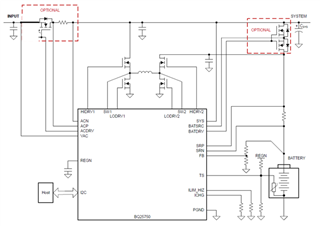

Other Parts Discussed in Thread: , TPS4800-Q1, LM7480, BQ25756

Tool/software:

Hello TI team,

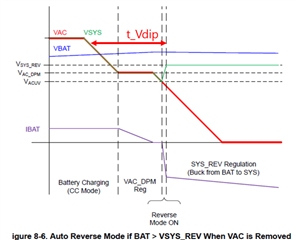

In my use case, I have problem related Auto-rever mode.

<Test setup>

VAC : Power supply 48V

VBAT : Battery (48V~58Vmax)

VAC_UV_level : 45V (HW resistor setting)

Disable Reverse mode

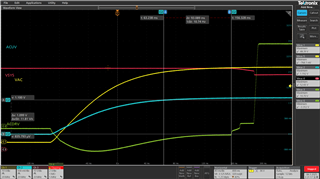

- The purpose of this test is to find auto-reverse voltage level to minimize the voltage dip when VAC is turned off and VBAT is switched on with 1A load condition. So I set the UV level is 45V.

But in this case, the charger doesn't charge and raises the VAC_DPM flag. so I set the UV level is 36V, It can charge.

Q1. What is the VAC_DPM HW level? it was register default set(4.2V).

Q2. Why is the charger raises the VAC_DPM flag not VAC_UV?

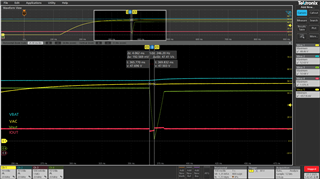

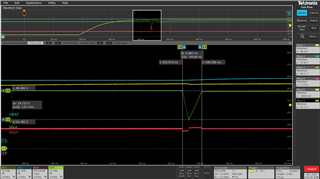

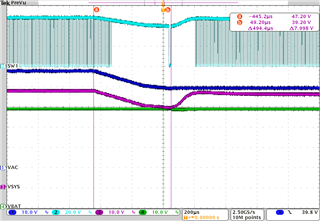

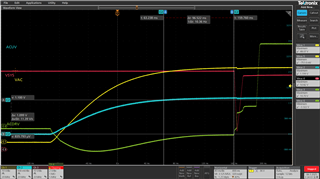

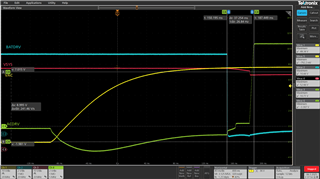

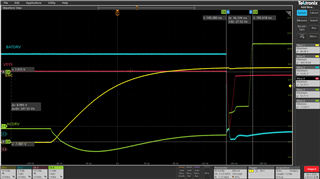

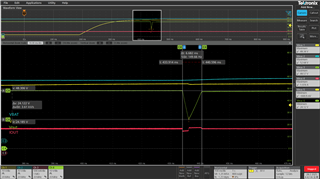

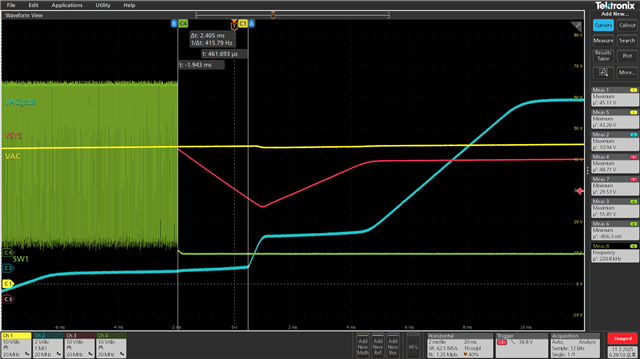

Q3. I want to minimize(t_Vdip) the voltage dip when changing VAC to VBAT with 1A system load. As attahc figure, the voltage level touched 10V. This may trigger under-voltage protection in connected systems.

Do you have any idea for that?

Left : VAC(48V) --> VBAT(55V)

Right : VBAT(55V) --> VAC(48V)

- load is 50W(1A condition)

Thank you in advance.