Tool/software:

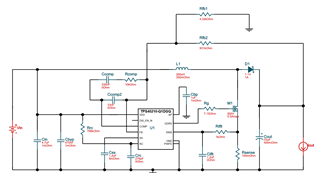

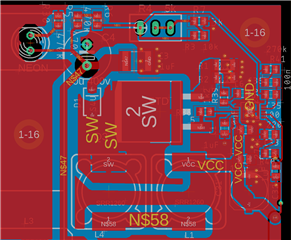

i created a classic boost for nixie, the first version was with poor perfomance, also i redign it and put bigger mosfet and bigger inductor:

rerouted ground with as much as possible short ways:

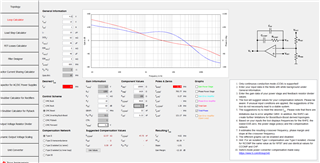

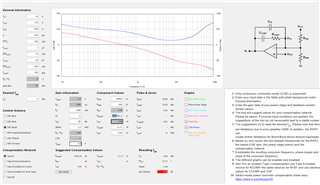

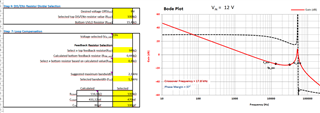

Input voltage : 12-19, output voltage 120-200v, 50-80mA, main MOSFET :

STB33N60M2, Mosfet, 600V, 26A, 190W,100mOm : https://www.st.com/en/power-transistors/stb33n60m2.html

Working frequncy 78KHz

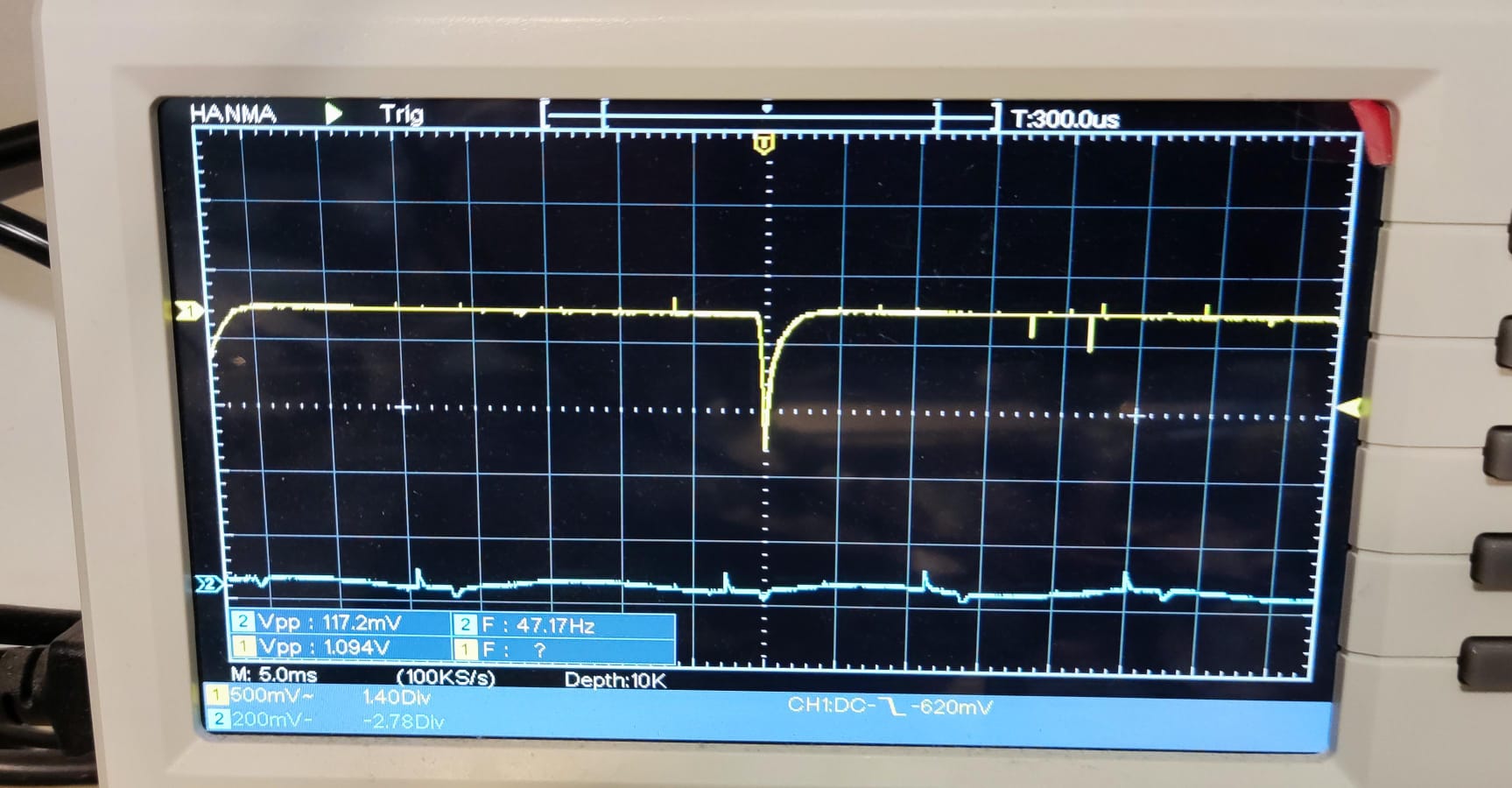

but now it is work only without load, with 2.5-3W laod it stop working and still restart

this is voltage on current sense :

this is voltage on power supply VCC :

but i habe connected 20uF C8, and add 680uF direct over C8

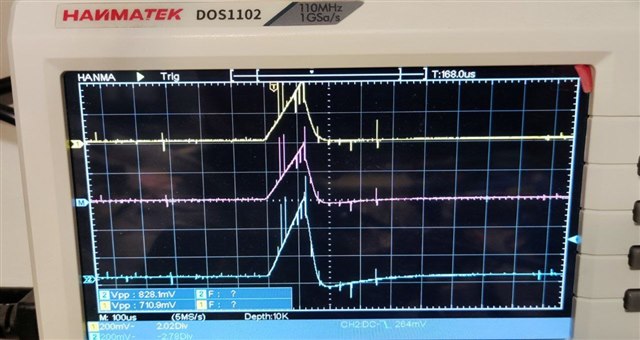

This is how it look on gate of MOSFET:

and this is source:

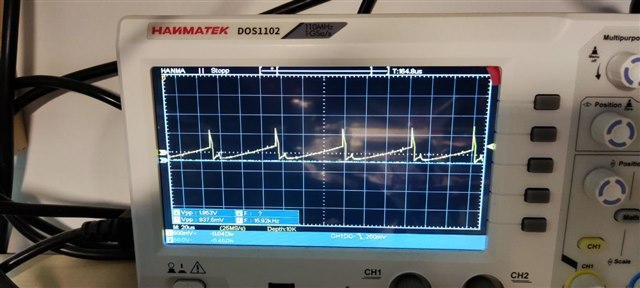

As i sad - this is only 2.5W load, without load it work, main coil will bu NOT saturted, i replaced it with big one, 350uH, up to 9A :

no more wild and crazy swing

no more wild and crazy swing