Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

Hi team,

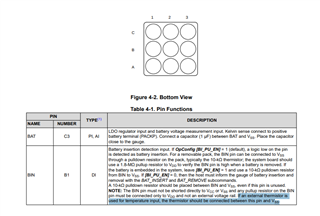

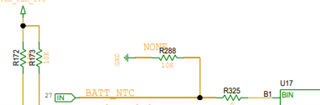

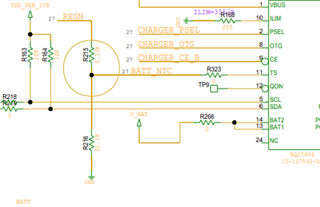

Please help to review BQ27427 schematics design, and engineers also attached a question list, please help to check those questions.

Any comments on schematic can be consolidated into that file as well.

Thanks for your support.

TI schematic review notes.xlsx9821-TI-review.pdf

BR,

Comi