Other Parts Discussed in Thread: TPS61377

Tool/software:

Hello,

I've gotten somewhat confused on the compensation network calculations for the TPS61376.

It seems following the datasheet example doesn't yield the component values that they've chosen.

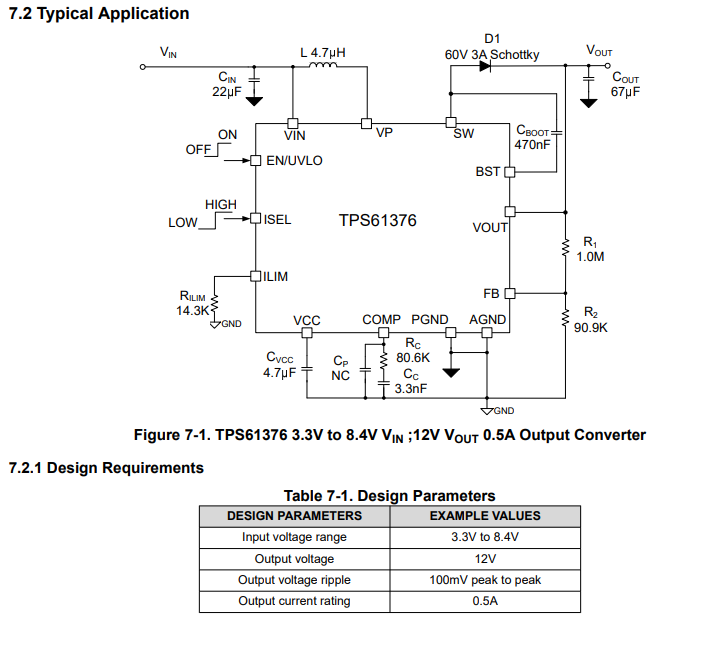

For example on figure 7-1 of the datasheet they have Cc as 3.3nF and Rc as 80.6k.

The output resistance Ro = Vo/Io = 12V/0.5A = 24Ω

First thing I am unsure about regarding the calculation for Rc is the Kcomp value which they give as 6.5A/V . Is this a constant or does it depend on the inductor value chosen? I understand the peak current calcs for the inductance, but where does comp voltage come from?

Anyway skipping past this detail and going directly to the calculation for Cc which is given be equation 18 as Cc=(Ro*Co)/2*Rc

If we were to take the values of the components shown in figure 7-1 for Ro, Co and Rc we get

Cc = (24Ω*67uF)/(2*80.6kΩ) = 10nF

The calculation gives 10nF for Cc while the example image shows this as 3.3nf??

To get Cc as 3.3nF Rc would need to be closer to 200k!

Now where am I going with this?

I am asking this because I was hoping to use this part on a project where I have a 5V input and 12V output with an output current rating of 350mA, inductor 6.8uH and an output capacitance Co = 330uF. Problem is I have serious doubts about calculating the compensation network components since even the example seems inconsistent.

Hope someone could give me some assistance in the calculation of the compensation network.

Many thanks!