Tool/software:

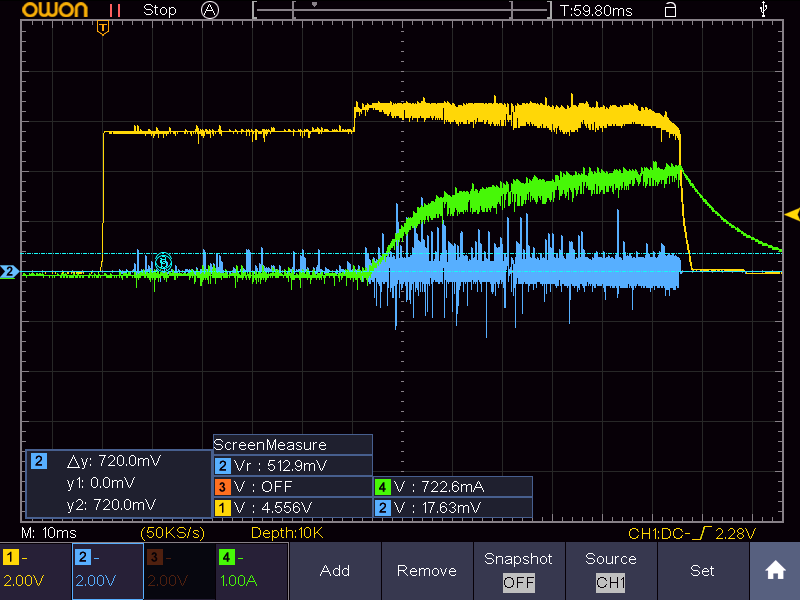

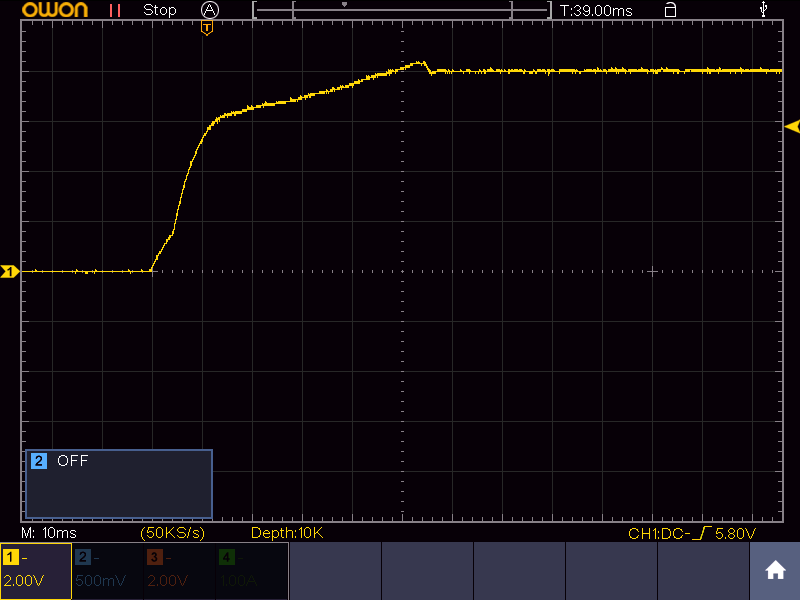

I found new problem with my design with UCC256404. When running device output is connected to load 80V / 4A, and load is disconnected, feedback primary (before optocoupler) is broken. There are destroyed zener diodes 24V, Zener diode 12V and 100R resistor between 80V and zener diodes 24V. Feedback is here feedback.pdf .

How to prevent to destroy feedback when load is fully disconnected?