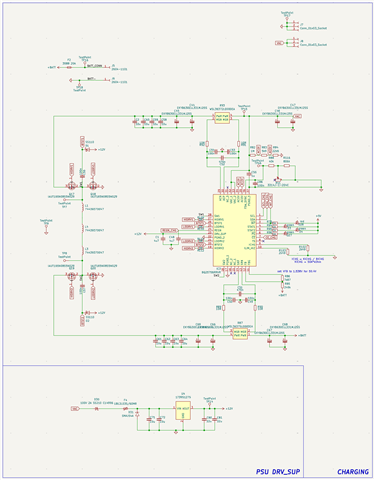

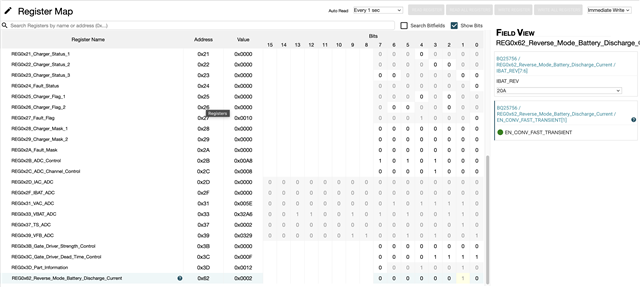

Other Parts Discussed in Thread: BQ25750, , BQSTUDIO, EV2400

Tool/software:

Hello,

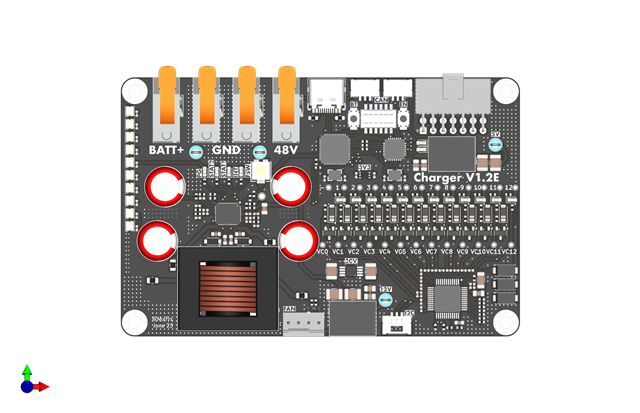

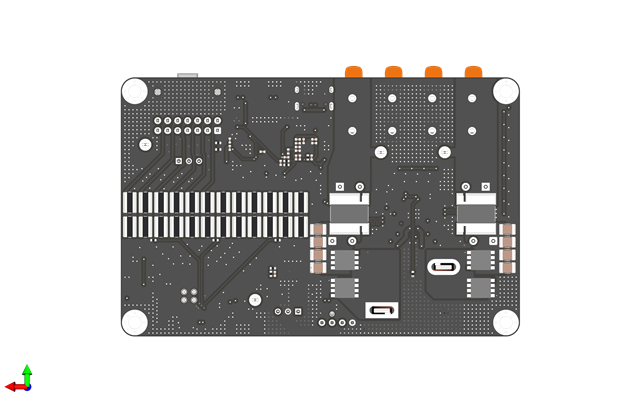

We have developed a new version of our Charger that uses larger MOSFETs than before and (as we believe) features an improved layout. Unfortunately, the new design is not functioning at all.

The problem:

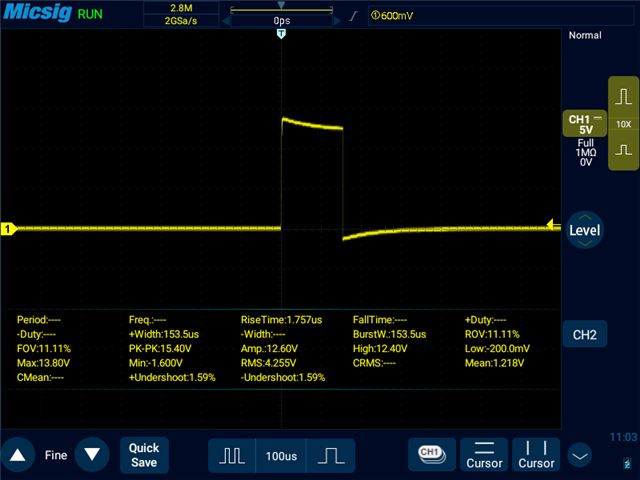

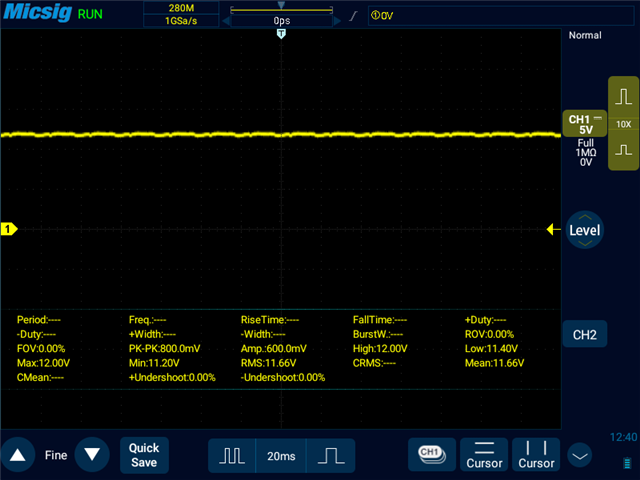

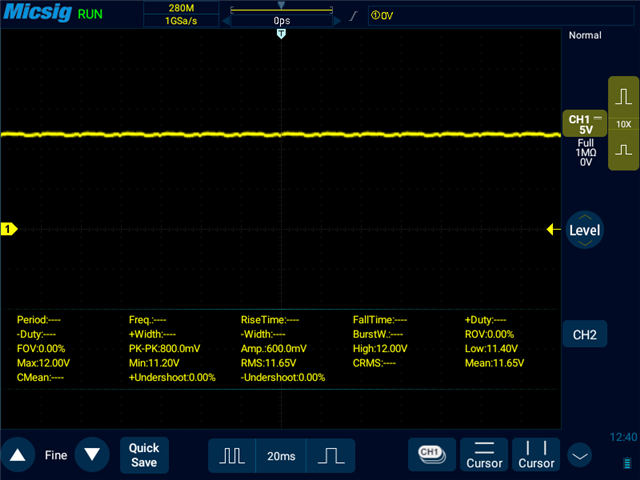

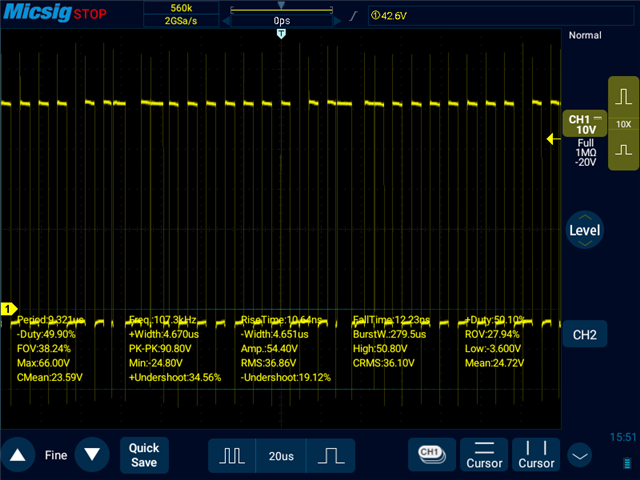

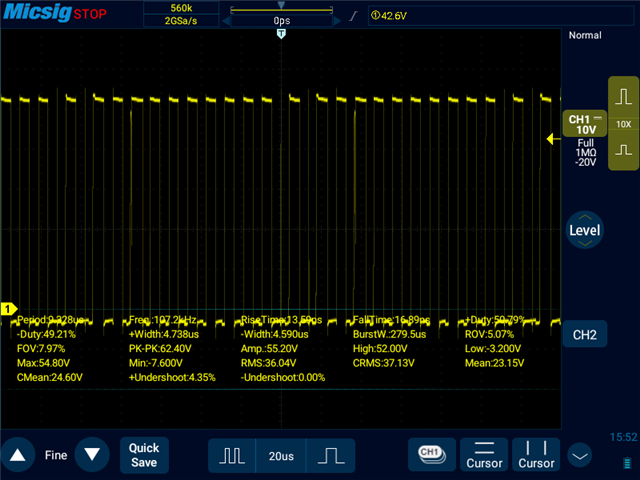

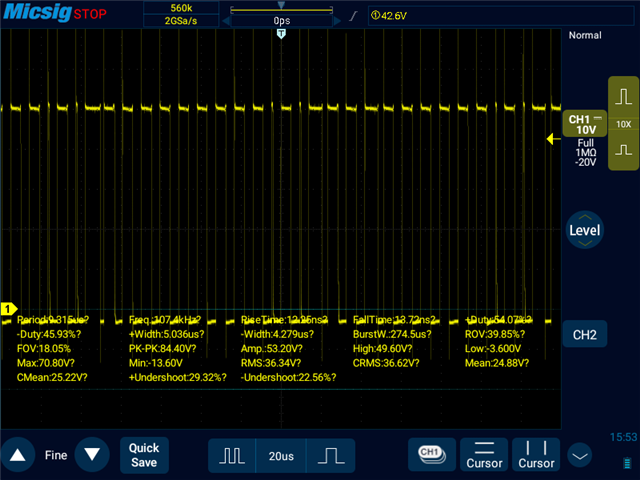

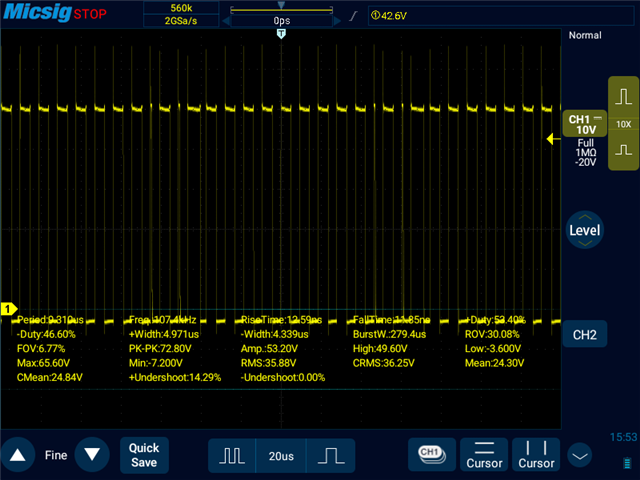

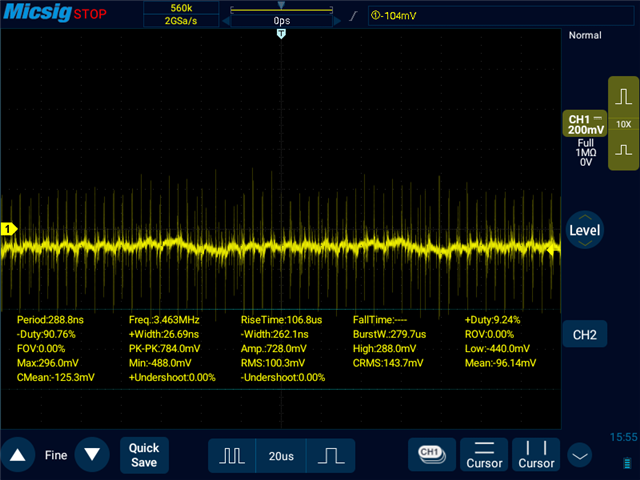

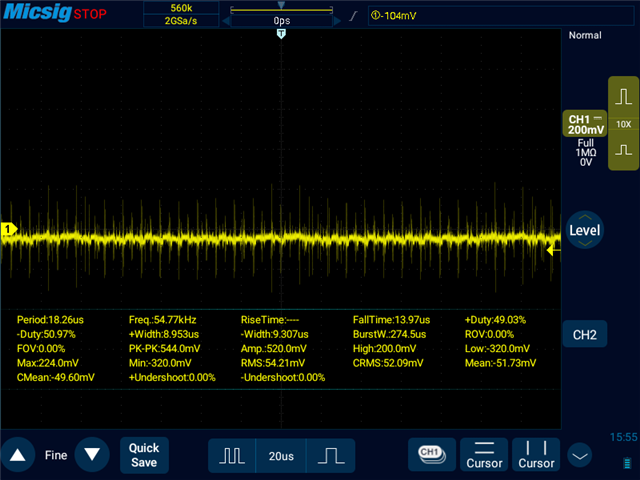

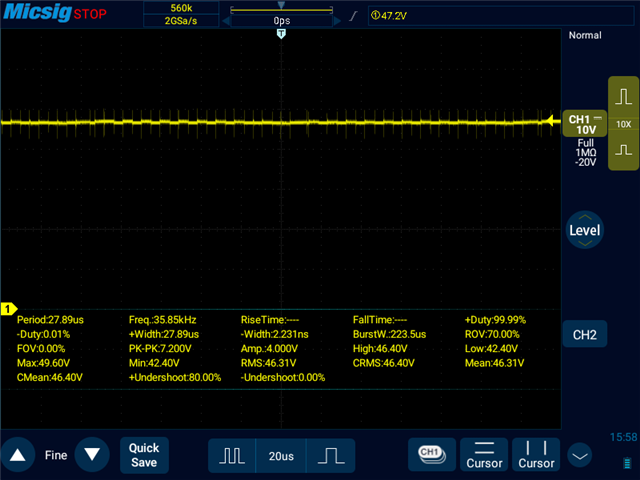

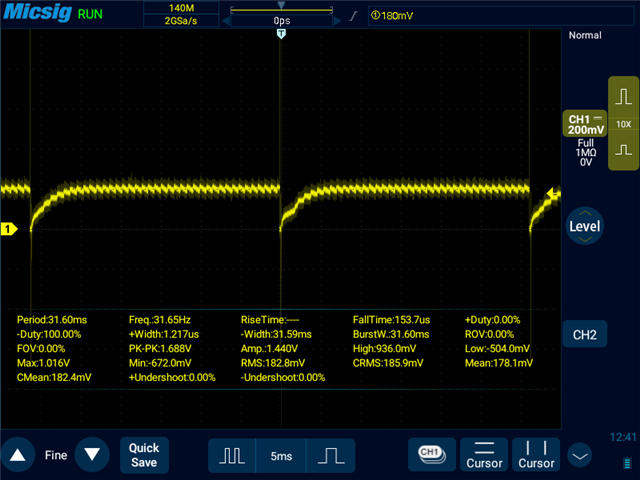

The INT pin is periodically pulled low at approximately 32 Hz for short pulses. ChargerGUI reports no faults or errors. No current is flowing through the board. The low-side MOSFETs appear to switch correctly: the gate voltage shows a clean digital signal with good rise and fall times and no ringing. However, the high-side MOSFETs are not switching properly — the gate voltage rises slightly but then quickly stops. (Screenshots are attached.)

What we have tested so far:

* Increased dead time to maximum and various random values between max and min → no change.

* Increased bootstrap capacitors from 100 nF to 470 nF, then to 1 µF → no change.

* Verified that gate driver strength is set to ‘fastest’.

* Verified that switching frequency (fsw) is set to 200 kHz.

* Disabled temperature sensor using ‘EN_TS’.

* Enabled ‘DIS_CE_PIN’.

In the ‘Status & Faults’ tab, only the ‘FSW_SYNC_FLAG’ is green; all others are off.

Previously, we used the SIR880BDP-T1-RE3 MOSFETs. Now, we are using the IAUT165N08S5N029ATMA2 and the FDBL86366-F085 on two otherwise identical boards. Both exhibit the same behavior.

High side MOSFET gates (both show identical pattern):

Low side MOSFET gates (both show identical pattern):

Any help diagnosing this issue would be highly appreciated.

Thanks,

Max