Other Parts Discussed in Thread: TPS1HTC30-Q1,

Tool/software:

Dear TI experts,

My customer have a question about applying PWM signal to EN pin. Please check the schematic first.

- They checked 6A current output on VOUT[X] pin if EN pin is 5V constant.

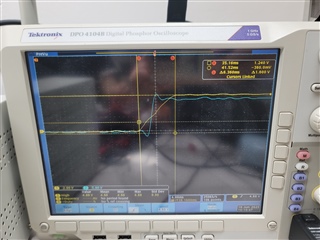

- But if they apply PWM signal to EN pin, they have some troubles.

1. What is maximum current output of VOUT[x] pin if 200Hz PWM signal is applied to EN pin? (Maximum input current of VS[x] is 10A.)

2. What is maximum current output of VOUT[x] pin if 960Hz PWM signal is applied to EN pin? (Maximum input current of VS[x] is 10A.)

3. What is maximum and minimum value of PWN frequency which can apply to EN pin?

And, Could cyou check the same question in case of using TPS1HTC30AQPWPRQ1?

- They checked 8A current output on VOUT[X] pin if EN pin is 5V constant.

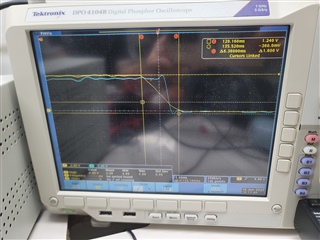

- But if they apply PWM signal to EN pin, they have some troubles.

1. What is maximum current output of VOUT[x] pin if 200Hz PWM signal is applied to EN pin? (Maximum input current of VS[x] is 10A.)

2. What is maximum current output of VOUT[x] pin if 960Hz PWM signal is applied to EN pin? (Maximum input current of VS[x] is 10A.)

3. What is maximum and minimum value of PWN frequency which can apply to EN pin?

Please check these issues. Thanks.

Best regards,

Chase