Tool/software:

Hello Mike,

1. The Excelsheet calculator provided mentions Dmax as 0.66 ? datasheet says it can go upto 95%. Can we manually Adjust Duty cycle as per our requirement ?

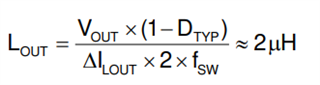

2. The excel tool considers 20% ripple of output inductor current while calculating Lmag, can i consider 40% ripple current ? what are the implications overall on the converter operation? OTS parts are readily available if i consider 40% ripple.

3.can i consider 10% ripple current ? what are the implications overall on the converter operation? OTS parts are readily available if i consider 10% ripple ?

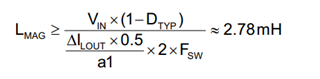

4. additionally, the excel tool calculates Lmag value considering Typical Voltage, not minimum Voltage. i think there's a correction to be made in the calculation sheet.

5.

As per your suggestion, I'm substituting Dmax in place of Dtyp, Vin min, in place of Vin in the above formulae to calculate Magnetizing Inductance, is that correct ?

6.

I'm substituting Dmax in place of Dtyp, in the above formulae to calculate output Inductance value, is that correct ?

7. sharing Two excel sheets, Let me know if any corrections are required. Please review the files. Especially Loop response values for 24V variant.