Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

Hello @Adrian,

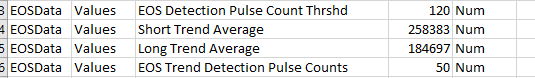

We are about to finish the learning cycle for our 13000mAh LiSOCl2 battery for EOS mode detection as per the 1 second pulsed load method after 5 hours of rest. Each time battery is drained by 2% and we have discharged 90% of battery. We have obtained readings of test each time after 2% discharge. Now, once this learning profile reaches 100%, how should we proceed further to detect EOS in order to timely replace the battery with the fresh one.

1. Please tell us step by step, how to utilize these obtained readings.

2. Which parameter is/are to be changed in BQ studio.

3. Should we program IC through BQ studio or Microcontroller over I2C.

4. In actual scenario, BQ35100 is interfaced with STM32 microcontroller over I2C in our product. So, should we send GAUGE_START / GAUGE_STOP commands from STM32 also each time the product powers-up.

Request you to elaborate in detail step by step. Images after 90% of learning cycle are attached for your reference.

With regard,

Sudarshan Chaudhary