Tool/software:

Hello EricLee

Can you please explain the technical reason to me how each of your recommended steps listed below can help in reducing the emissions.

- Make SW node copper area smaller.

- Add RC snubber between the drain and the source of the low-side MOSFET.https://www.ti.com/document-viewer/lit/html/SSZTBC7

- Populate a schottky diode in parallel with low-side MOSFET

- Use shielded inductor with minimized pin lead exposure. The pin leads are hidden on the bottom side in this example.

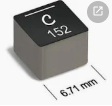

- Locate the 'dot' (or 'bar') direction of the inductor at the SW node.