Other Parts Discussed in Thread: LM5155,

Tool/software:

Hi TI,

How do I use "Power Stage Designer" and Excel "LM5155 LM5156 Quickstart Calculator for SEPIC" to select feedback loop compensation components for LM5156 in SEPIC topology?

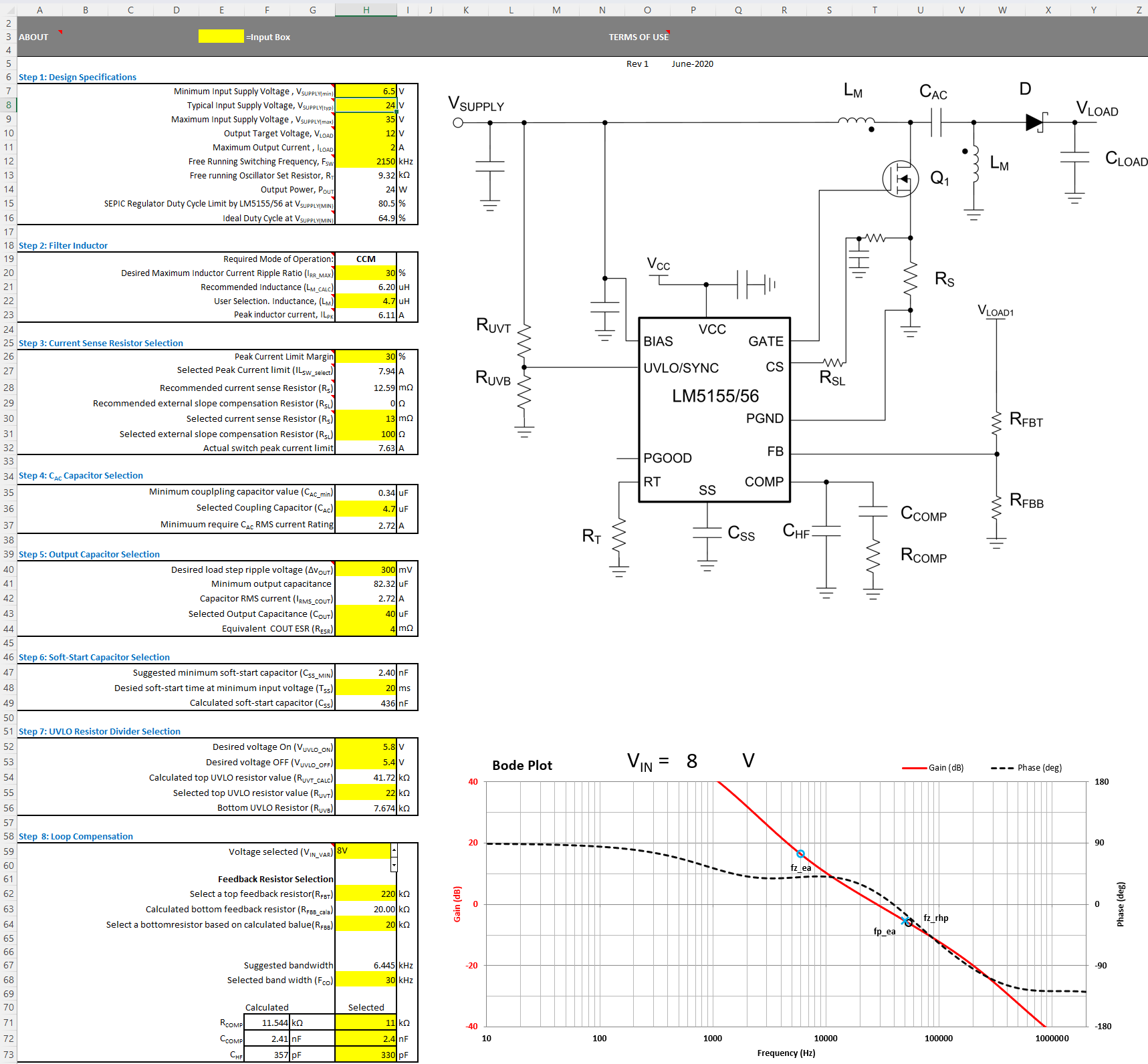

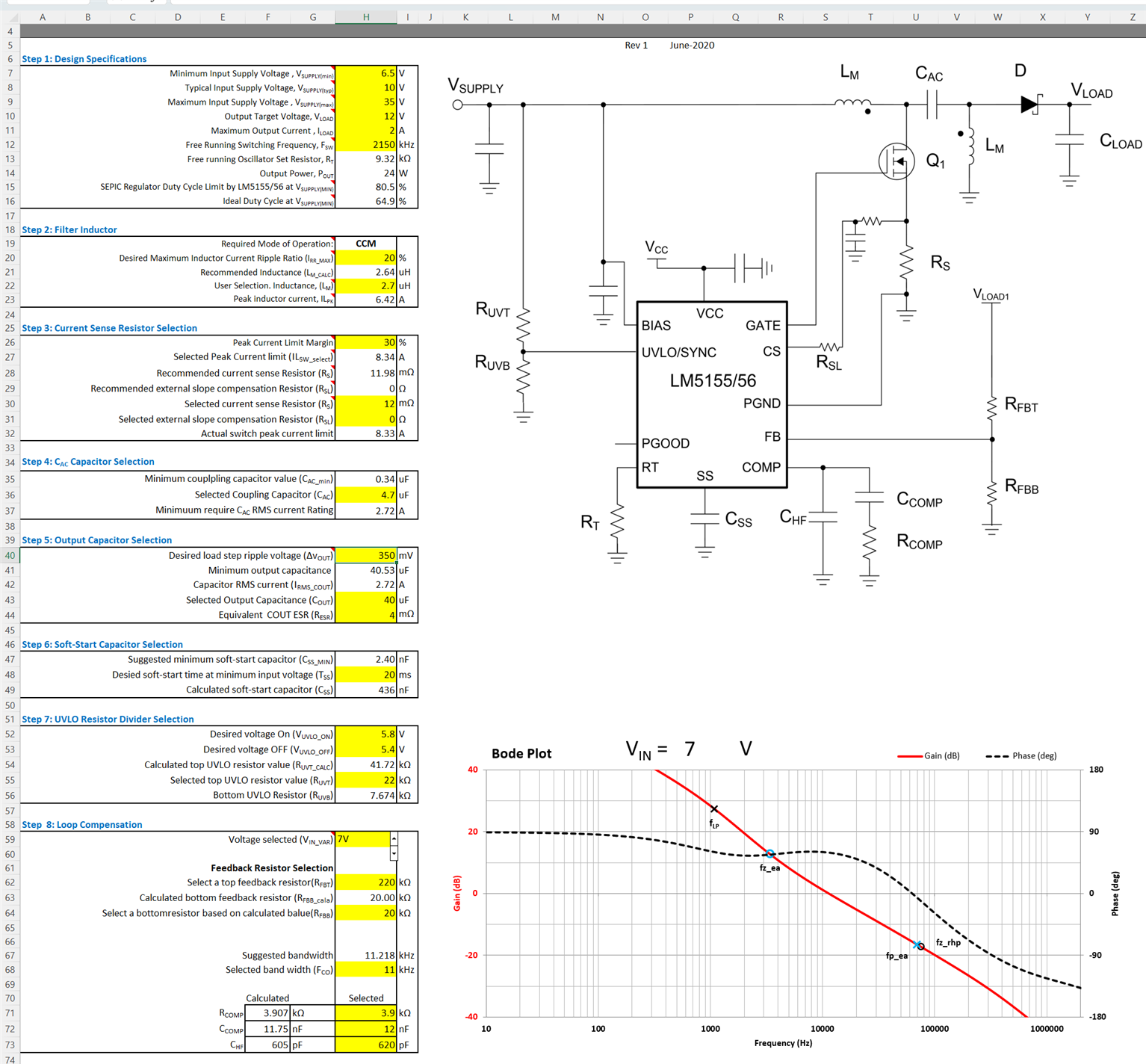

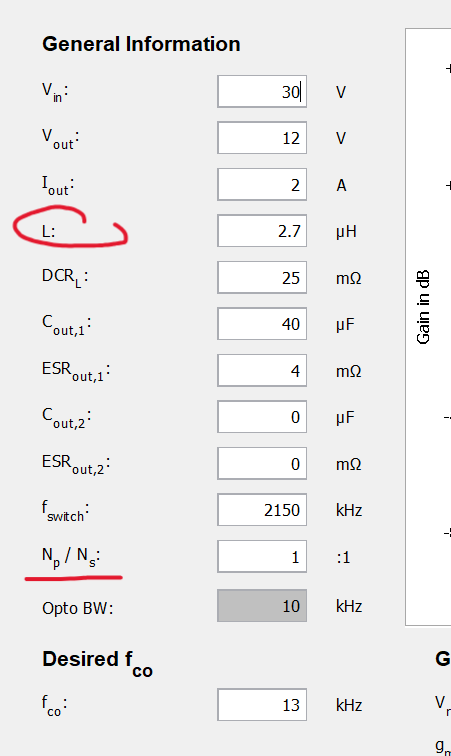

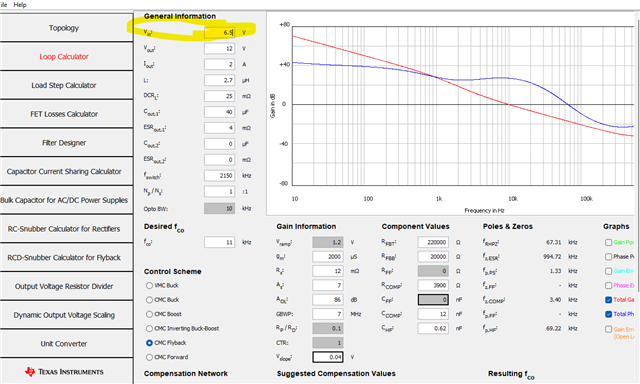

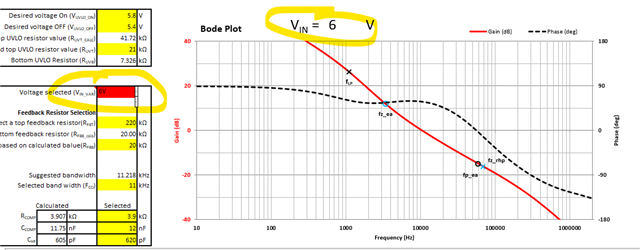

My goal is to design 12V/2A SEPIC SMPS with Vin 6.5-35V optimized for 10-30V range. Probably the most optimal inductors selection is L1=2.7 or 3.3µH, L2=4.7µH DCRL=38mΩ. Derated Cout=40µF, ESR=4mΩ at fSW=2.15MHz.

In my design I cannot use coupled inductors. Making custom ones is not feasible and there is also max height requirement which coupled inductors typically do not meet.

SMPS will be used to power circuits driven GPIOs, rather than audio frequencies, so probably I should select higher fcross.

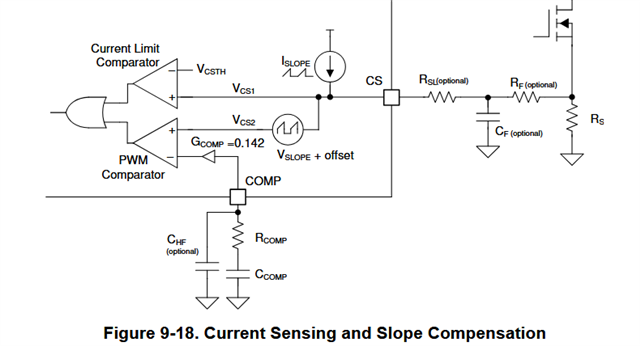

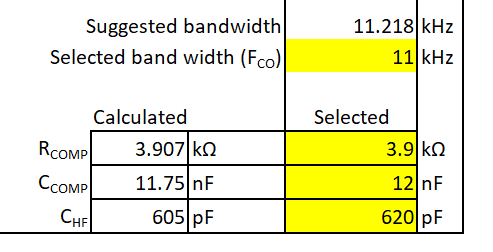

1. For the feedback loop calculations only L2 value needs to be considered, and I am not certain what value should be entered in TI Excel spreadsheet cell H22 (LM). Should I enter the selected L2 value or only half of this value? TI Excel spreadsheet probably assumes coupled inductors are used.

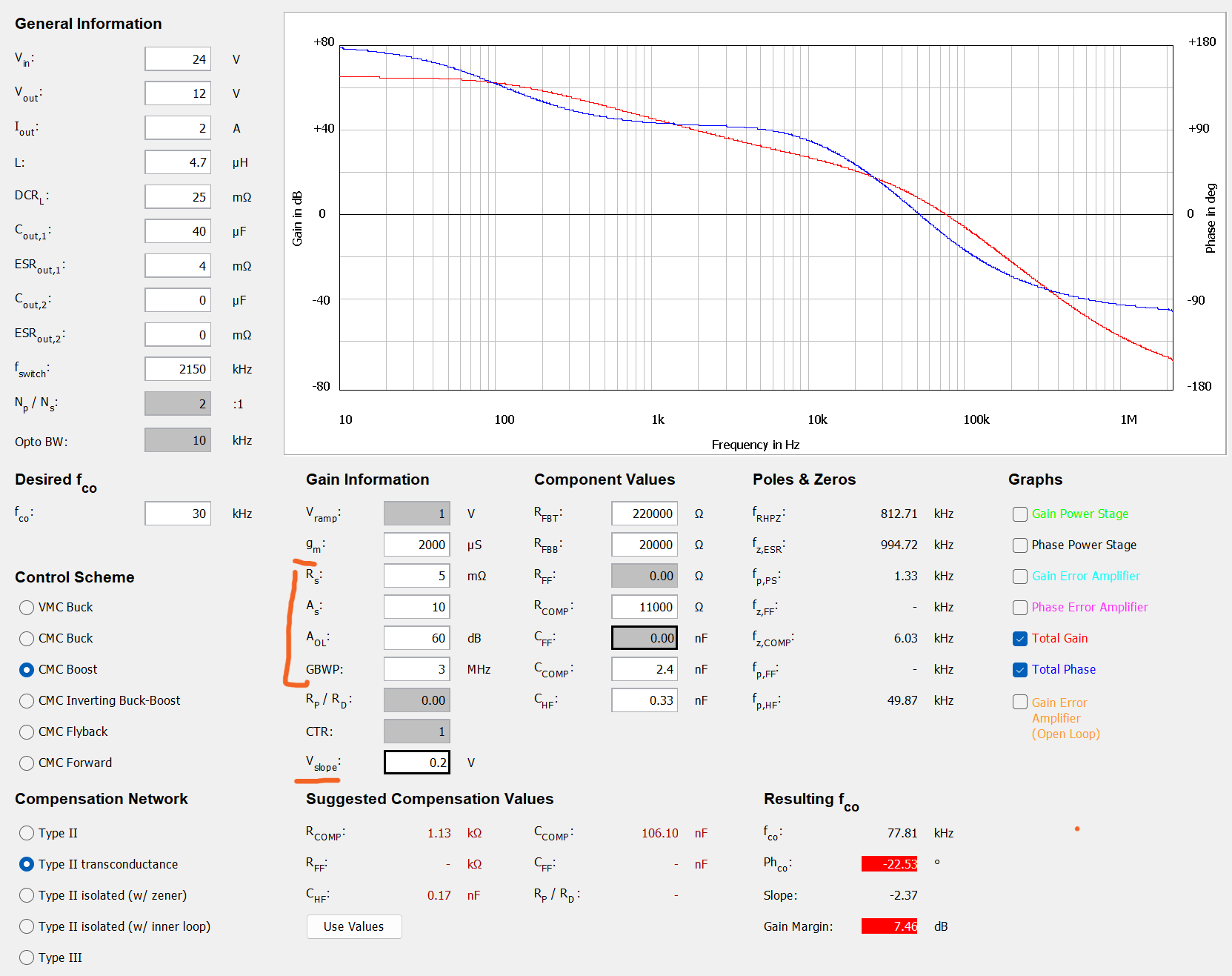

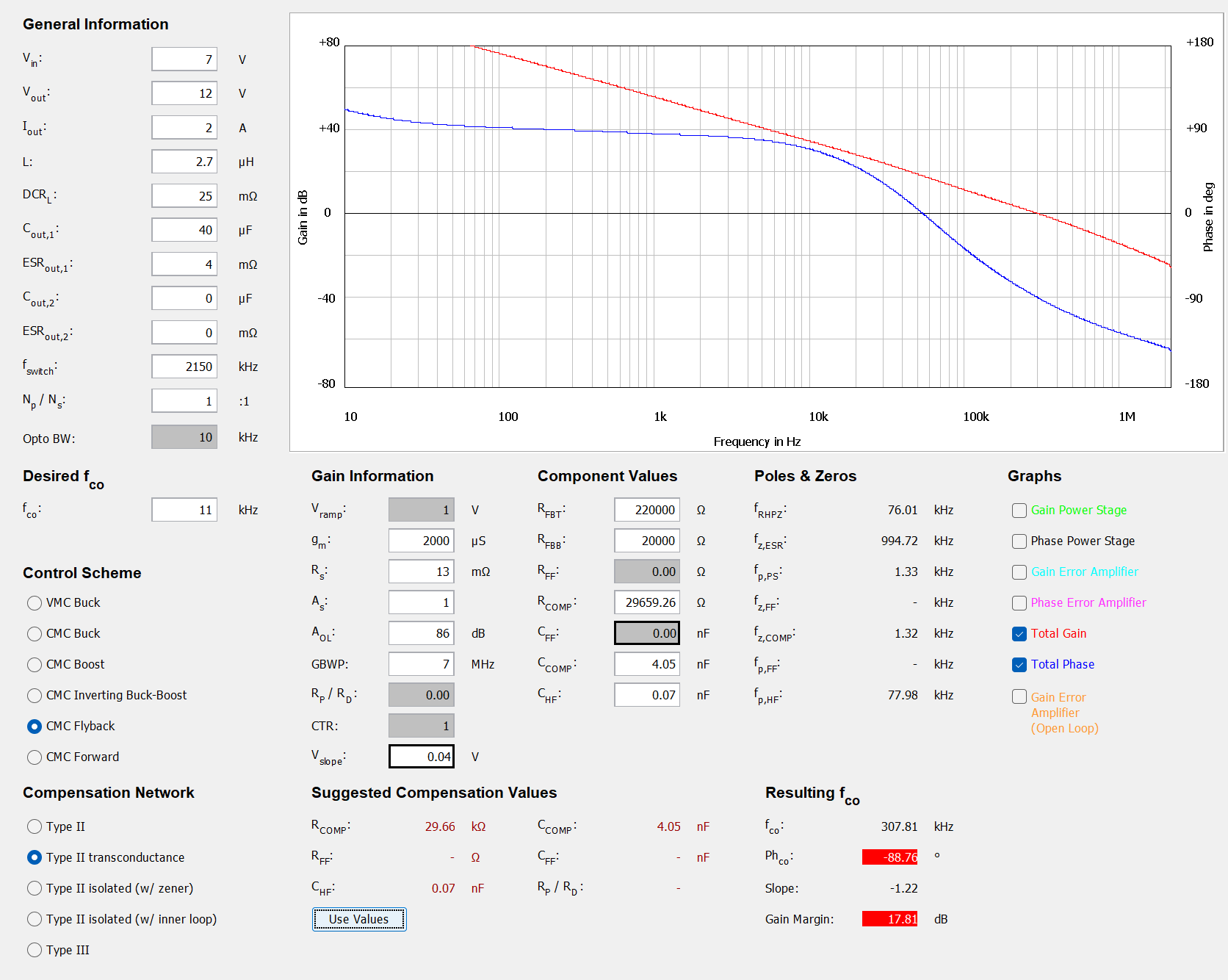

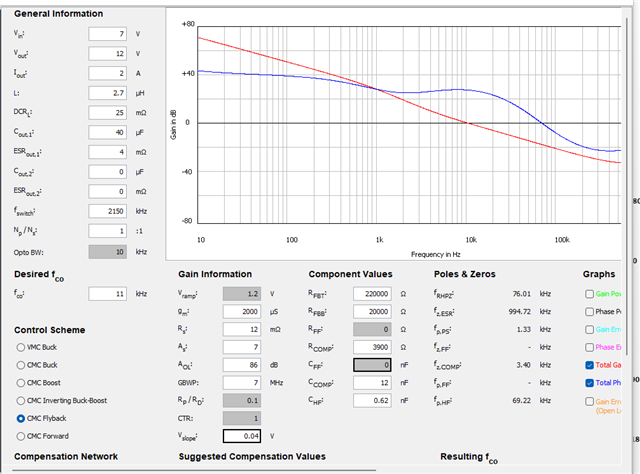

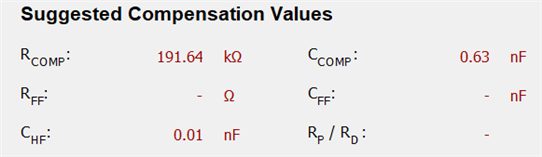

2. How to properly configure and use "Power Stage Designer"? SEPIC is not one of the available "Control Schemes".

Do I correctly assume that "Type II Transconductance" compensation network has to be selected?

What highlighted values should I enter for LM5156? (see image below)

3. DeepSeek provides the following advice:

a. place fz_ea below fcross (typically 1/5th to 1/10th of it)

b. place fp_ea above fcross (but below fSW/2)

c. set fcross ≤ fz_rhp/3

d. ofc, phase margin at fcross has to be ≤ 45° (phase -135° max)

Could you confirm the above makes sense?

In my case DeepSeek suggests target fcross=50kHz, but it may not be achievable with Type II compensator. However, fcross=40kHz seems achievable.

Please advise.

Kind regards,

Thomas