Other Parts Discussed in Thread: TPS92640

Tool/software:

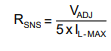

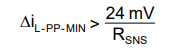

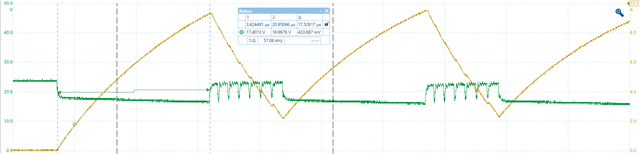

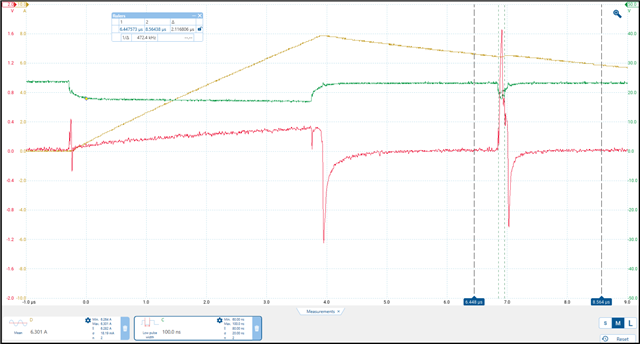

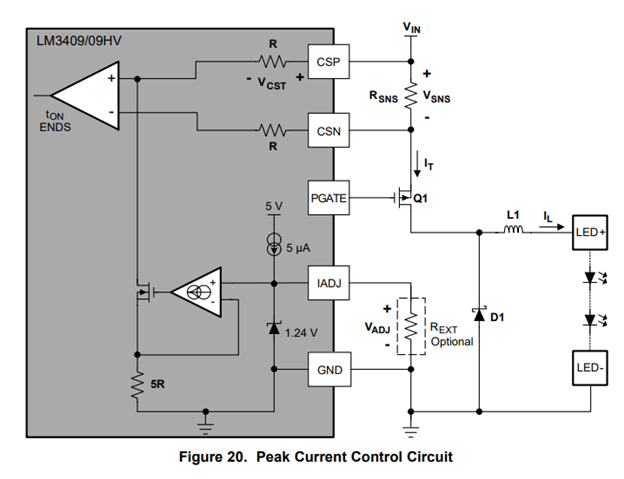

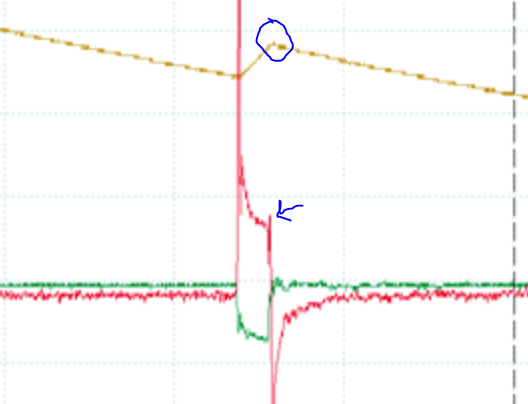

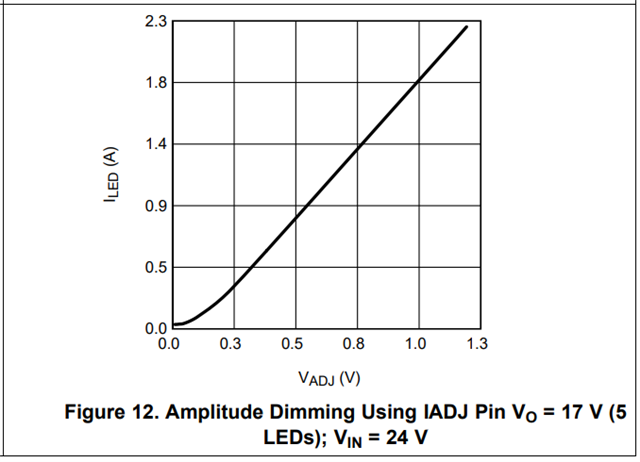

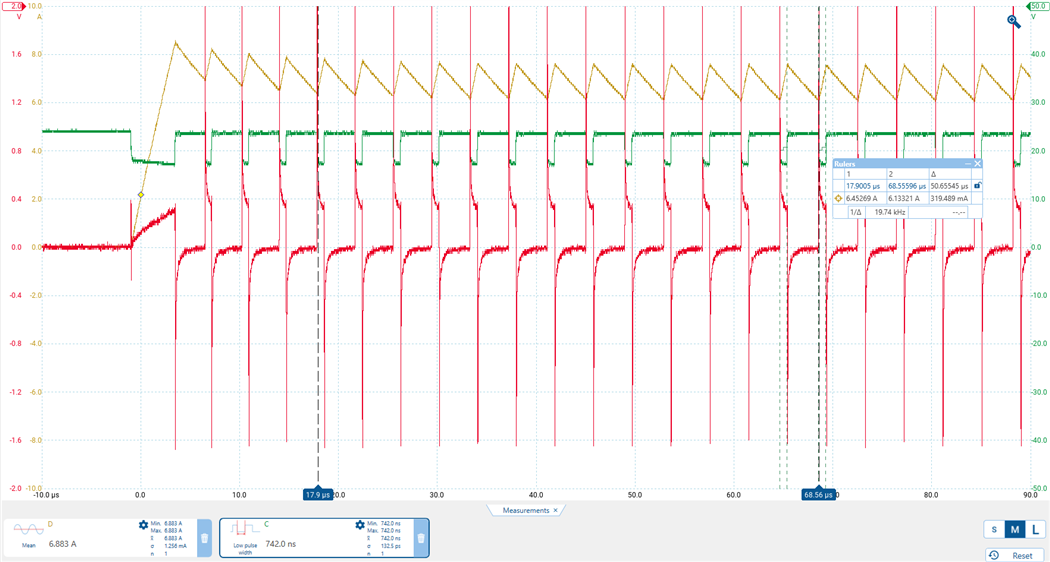

We successfully made designs with LM3409 before, but this one does not work as it should. As you can see below, most of the times when the P-FET is turned on (gate voltage seen in green) the LED current (shown in yellow) barely rises before the FET is turned off again. The time corresponds closely to the minimum on-time specified in the datasheet. I also posted the schematic we are using, the only difference to previous projects is, that we only drive a single LED, meaning V_IN is 24V while V_OUT is only 4V with maximum LED current of 10A. The oscilloscope screenshot is at V_ADJ of 1.24V.