Tool/software:

Hi E2E community,

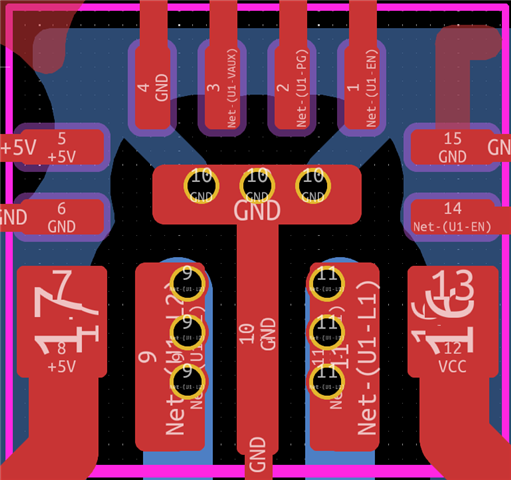

I've built some PCBs with TPS630701, designing the pcb footprint as it was recommended in technical references. However, it seems like during reflow solder wicks into vias on pad 9-10-11 sometime leaving insufficient solder which leads to failures right after the reflow process or after being subject to minimal mechanical impact.

What sort of solution would you recommend to avoid failures? (Ideally solutions which won't make the PCB more expensive :)

Many thanks,

Ersin