Tool/software:

We are evaluating the design of a PSFB with 400Vin; 28Vout ; 200A.

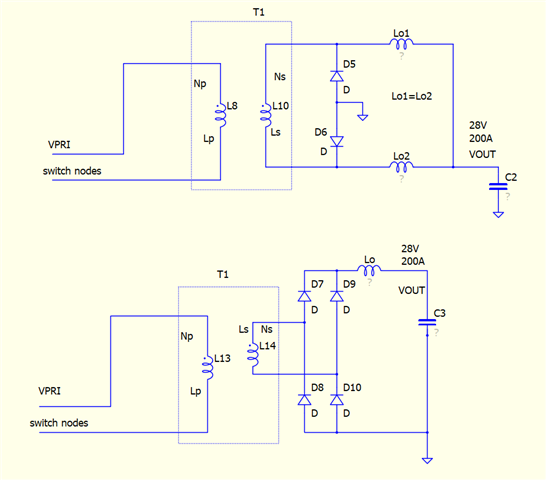

Our current ideas is to use the following output stage that use two transformers with series connected primary windings and parallel current doubler outputs.

In literature the basic design formulas of a PSFB use output architectures like single stage current double or full bridge recitiffer. We need help on identify the relationship between our architecture and one of the following two architectures in order to use the design formulas from the UCC datasheet or literature formulas. We must identify how Np1, Ns1, etc.. parameters modify from our architecture to/from one of the following basic architectures.

Thanks