Hello,

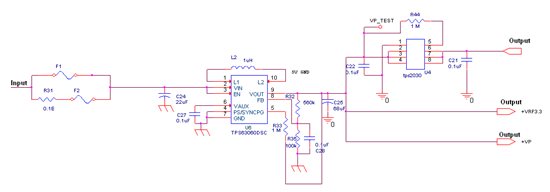

My customer is evaluating TPS63060 using EVM. They sweep the output voltage using external DAC and a resistor (see attached schematic).

They developed transfer curves (three plots - see attached EXCEL file with three tabs). The Y-Axis is the output voltage and the X-Axis of the transfer curves is the MTR_PWR_ADJ signal in the schematic.

First plot shows Vin of 4V no load and it looks great.

The second plot Vin=4V, with 15ohm load and the output looks reasonable other than when the output is around 3.5V (seems like some sort of a hysteresis).

The third plot shows Vin=3.3V, with 15ohm load and the output "wobbles" in the middle. The transfer function is not monotonic.

Is the circuit going unstable? Different compensation required?

Thank you,

Alex