Hello all!

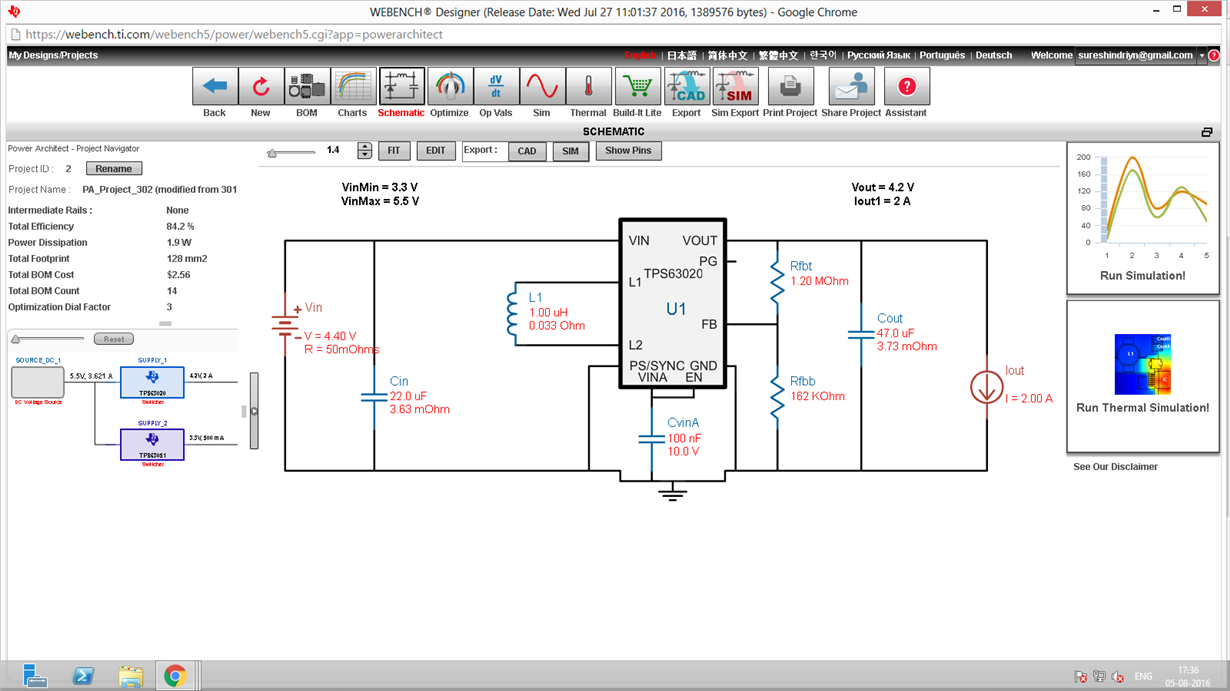

For my first hardware project, I've designed a power supply to power SIM808(4.2V @ 2A Peak) and MSP432(3.3V @ 500mA Peak). Both the regulators are powered by either Li-Po battery or 5V DC supply(selected through P-MOSFET). I simulated the designs from webench and copied the same schematic. It'd be very helpful for me if you can share your comments on the design. This's my first design and I don't have any prior experience in designing hardware. Any feedback you provide will be of great help.432+808_Power.tiff

Thanks

Suresh