Other Parts Discussed in Thread: , TPS40200

Dear,

I've got some issue to make the TPS55340 working properly.

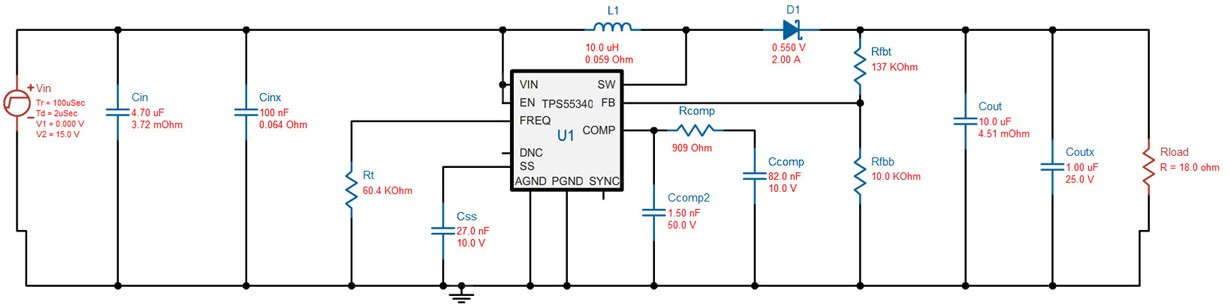

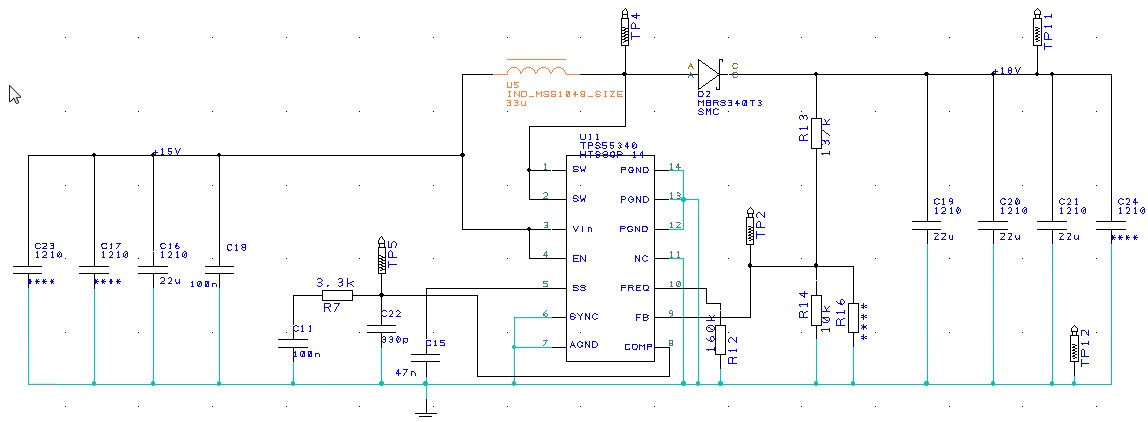

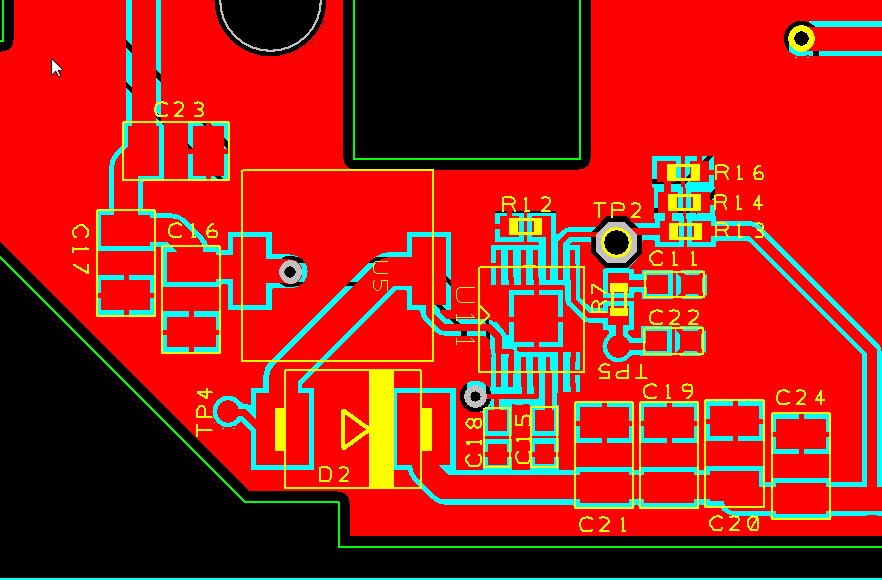

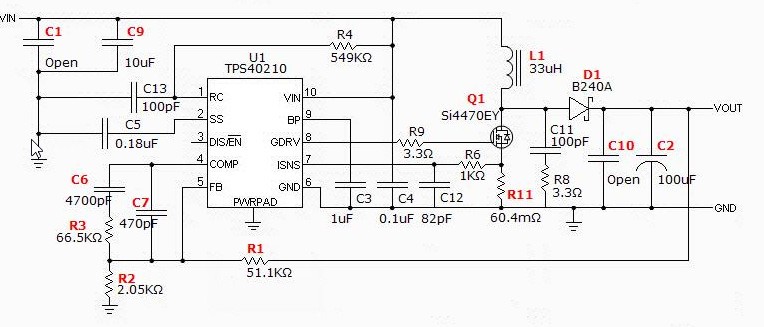

Need to create a 18V continuous based on a 15V +/-10% for a load of lower than 1A => step of about 1A for a dv lower than 0.5V.

I use the excel file to define the value of the component to use for the compensation.

I try many different compensations solution but I have always the same behavior:

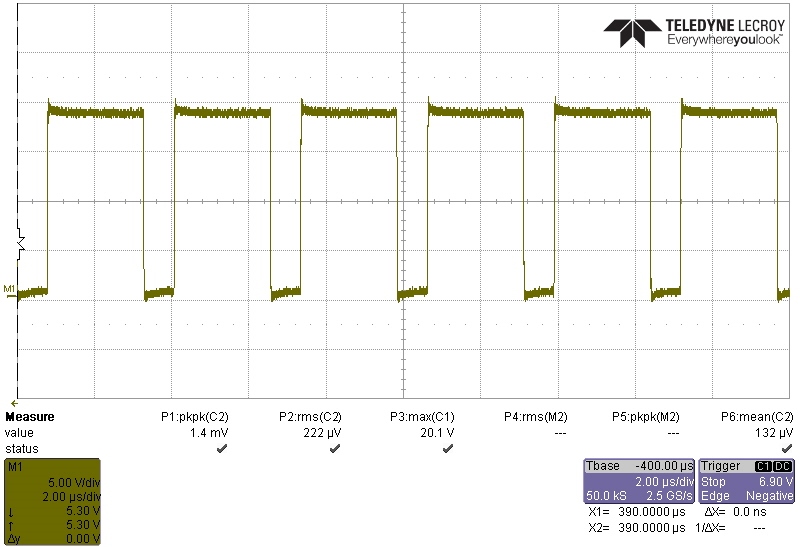

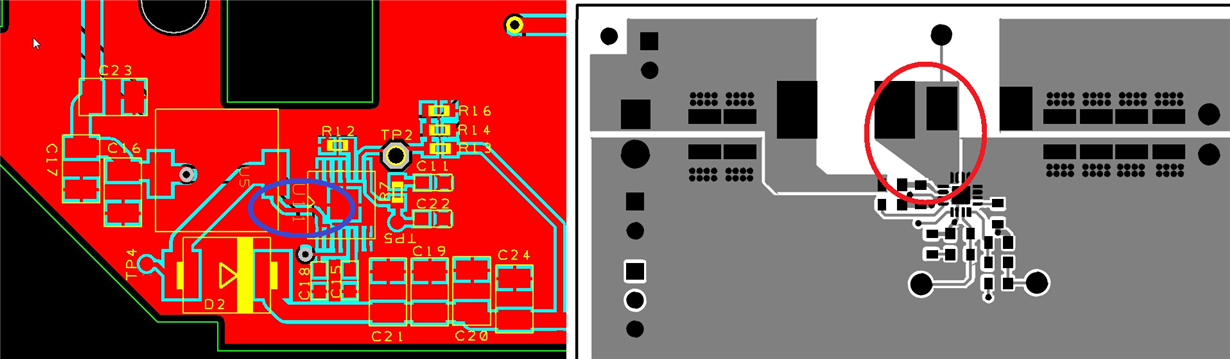

For instance, at 14V, I've this when I lood to SW pins of the component: (stable and almost constant => under 20OHm load)

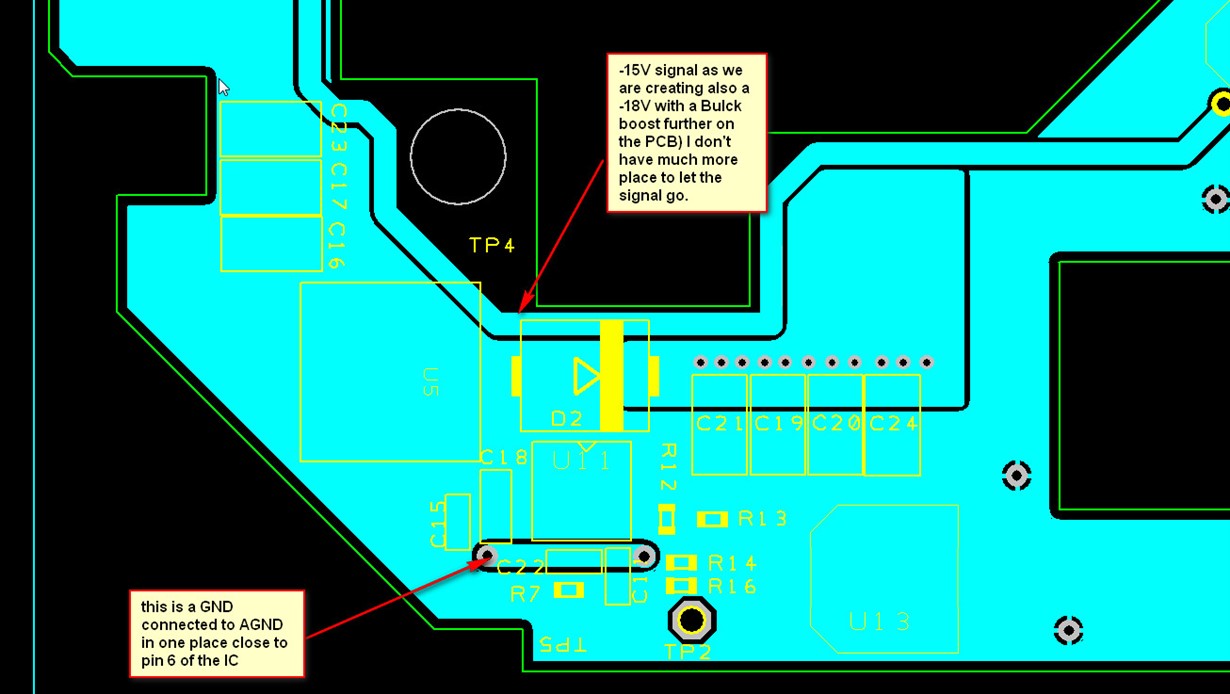

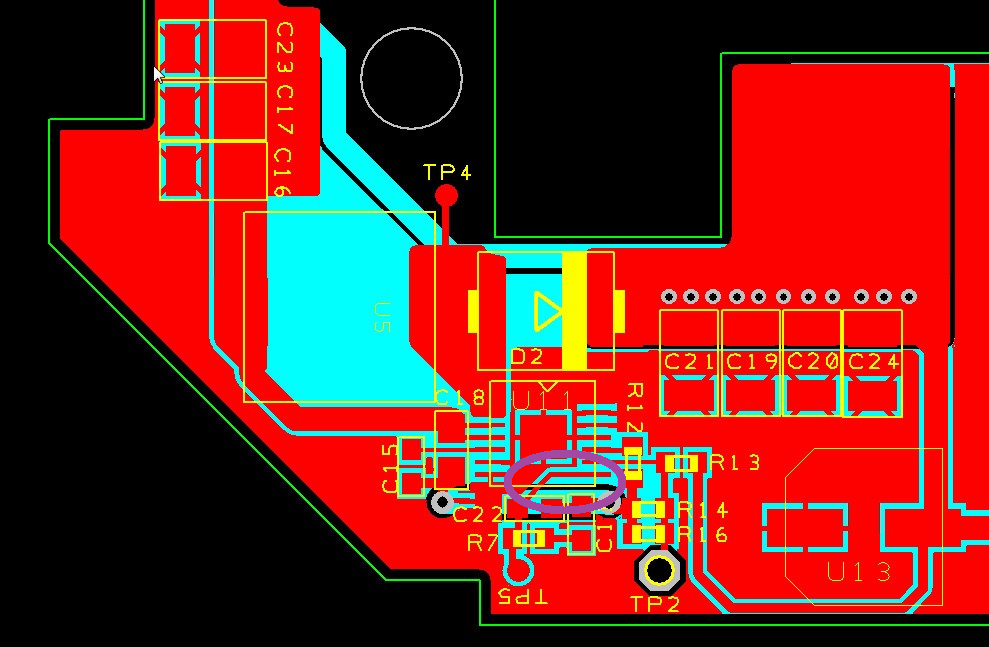

When I increase the input voltage the duty cycle start to oscillate and the frequency seems to change. On the table it seems to work but as soon as I place it in our product and under temperature after short time under high load the regulation stop completely working (I got lower than 15V instead of 18V). I need to switch OFF and ON to make it work again ....

Do you know what is the root cause of this issue ?

Thanks.

Best Regards,