Other Parts Discussed in Thread: LM3409, TPS92515, LM3423, LM5122, TPS40210

Dear TI,

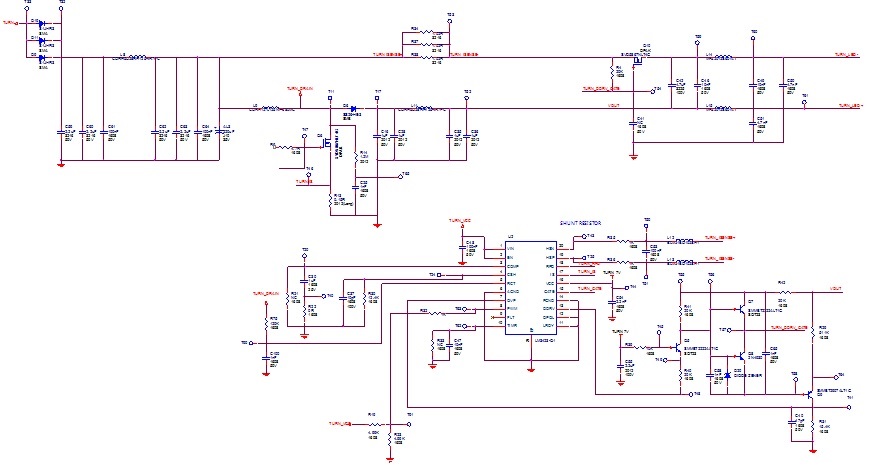

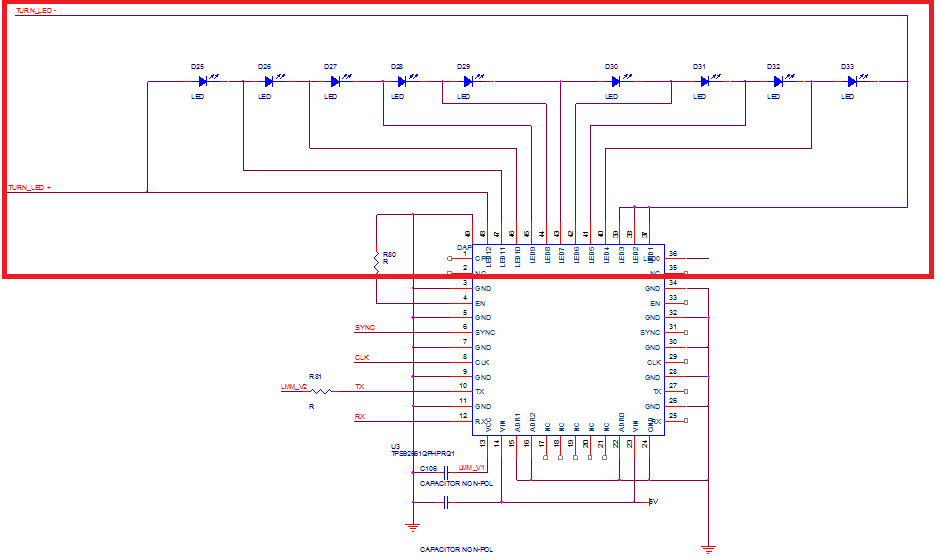

I am currently developing a car lamp.(TURN signal)

Here are two questions:

1. When using the buck-boost circuit, can LED0 ~ LED4 of TPS92661 be connected to LED- instead of GND?

2. possible to control using UART communication by changing to PIC?