Hi,

the current flyback design used LM2577 to boost +5V input to +15V (75mA) & -15V(110mA).

We using Cout - 330uF,50V

Cc - 330nF, 50V, X7R, 20%, 1812 package

Rc - 3.01K,1% 0805 package

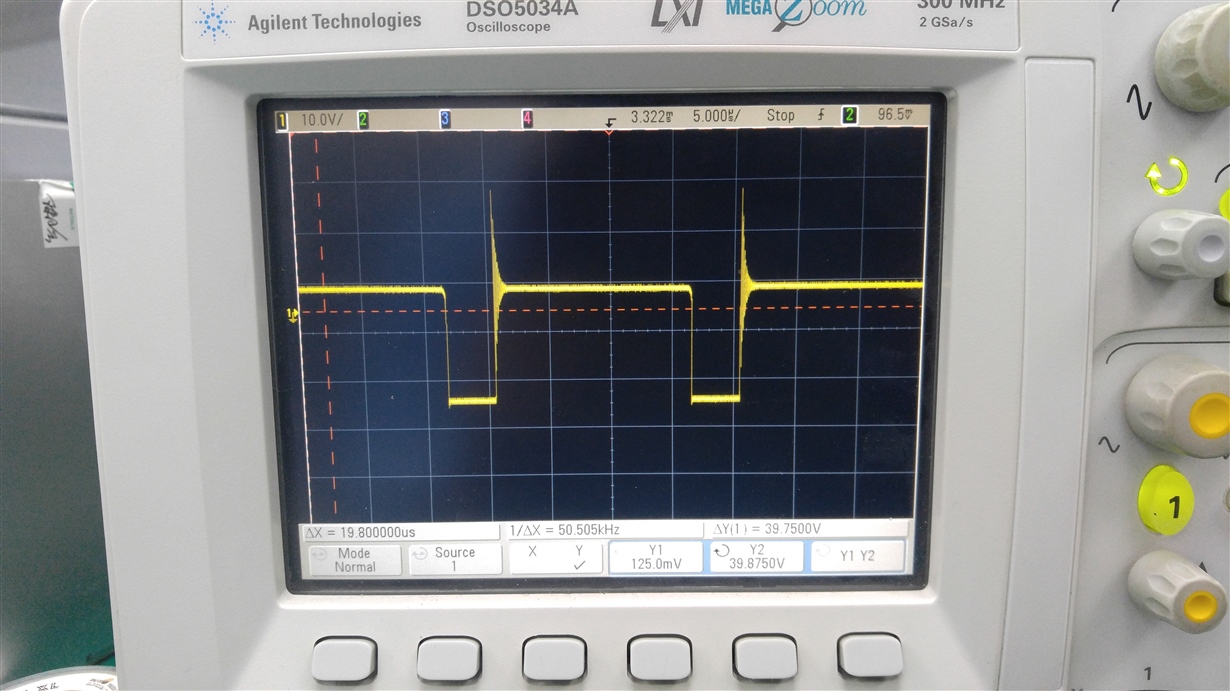

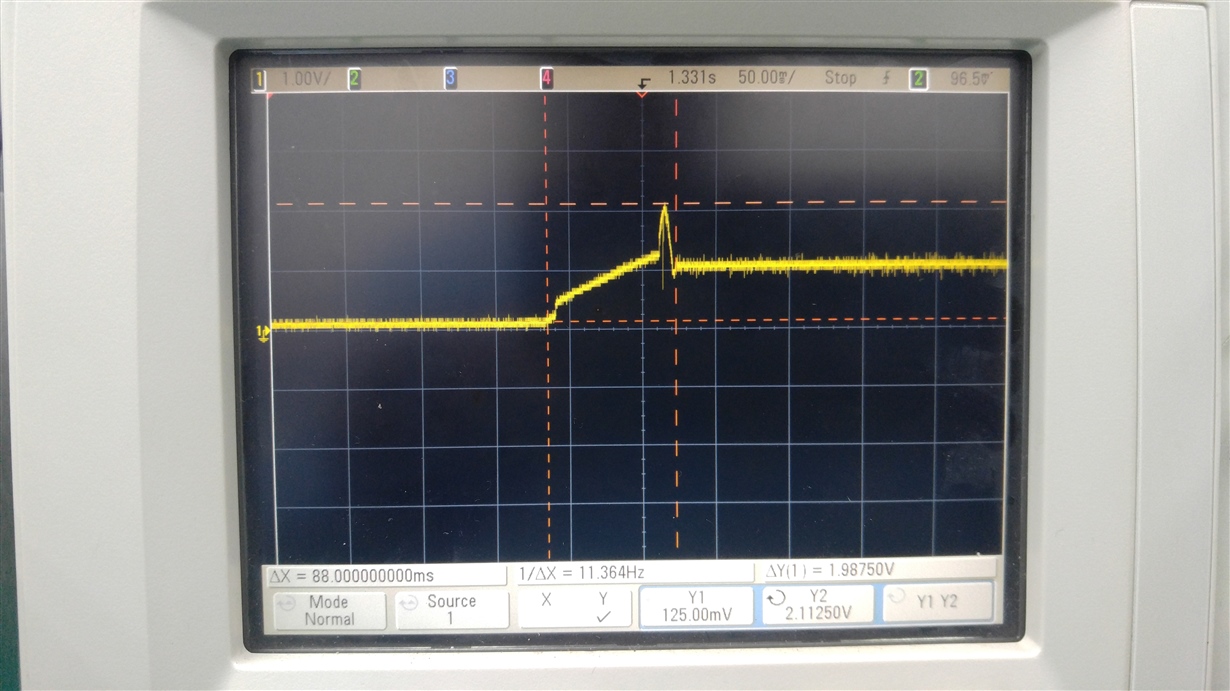

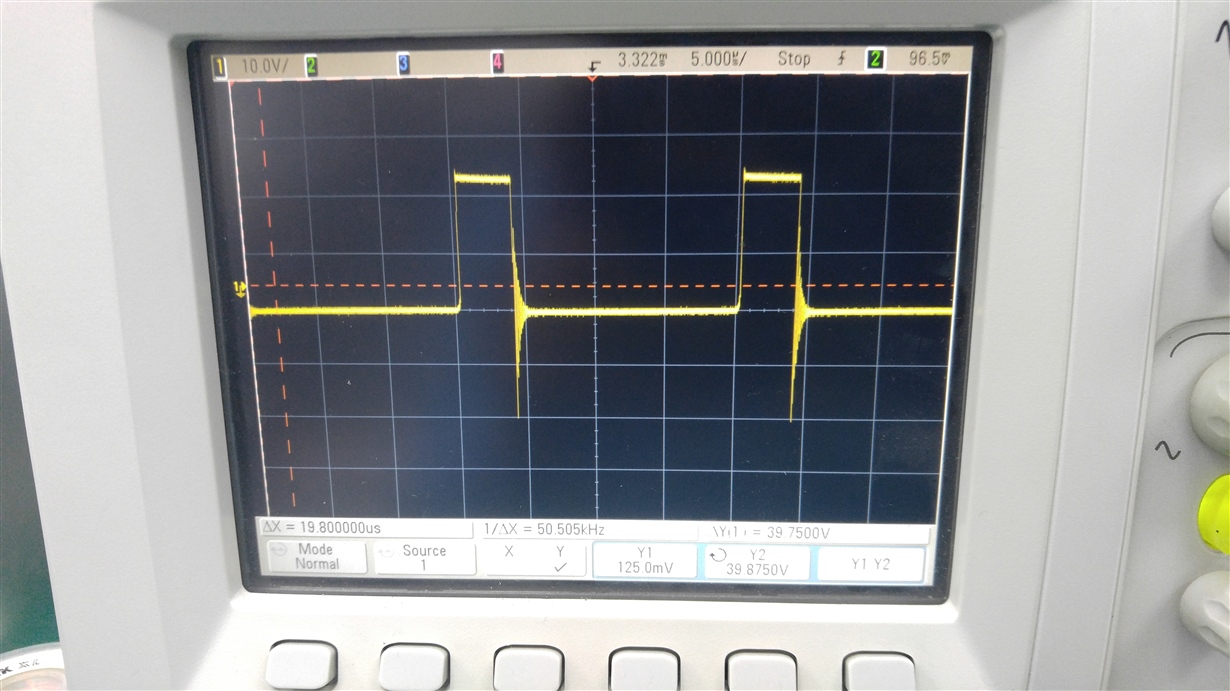

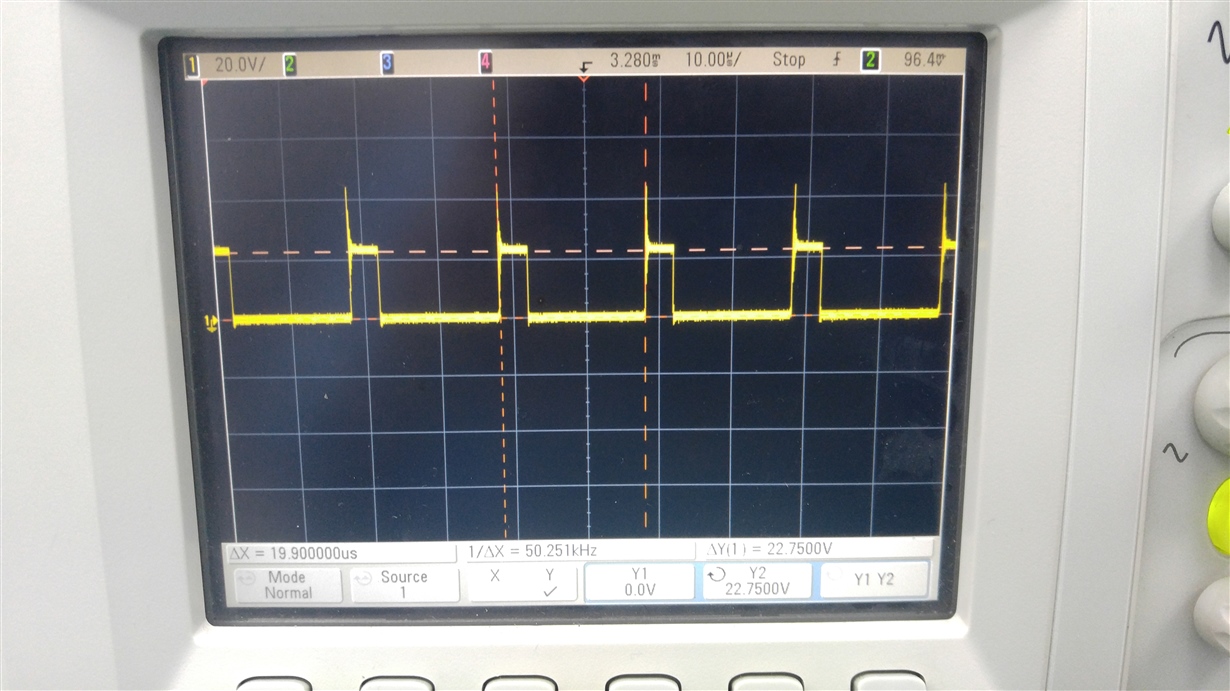

It runs at 50KHz freq. Ripple measure @ load - 200mV P-P

We are facing 2% of compensation capacitor failure during functional test. i.e- Capacitance dielectric fails and IR measure in Ohms instead of Mohms.

Can you please comment what can cause compensation cap failure ?