Other Parts Discussed in Thread: TPS63050

Questions:

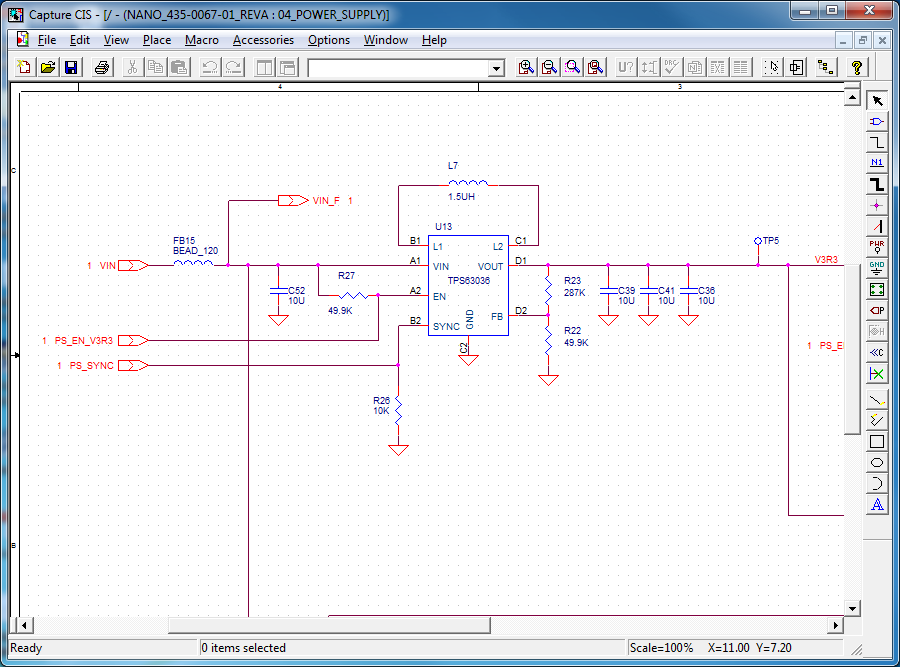

the TPS63036 data sheet, rev October 2015, section 7.4.4 says "If PS/SYNC is set low then power-save mode is entered when the average inductor current gets lower than about 100 mA." and "When the load increases above the minimum forced inductor current of about 100 mA, the device will automatically switch to PWM mode."

From data sheet figure 3, the average inductor current is the average load current plus the (small) resistor divider current. But what is the "minimum forced inductor current"? Also there is no specification on "about 100 mA". What is its range in production devices?

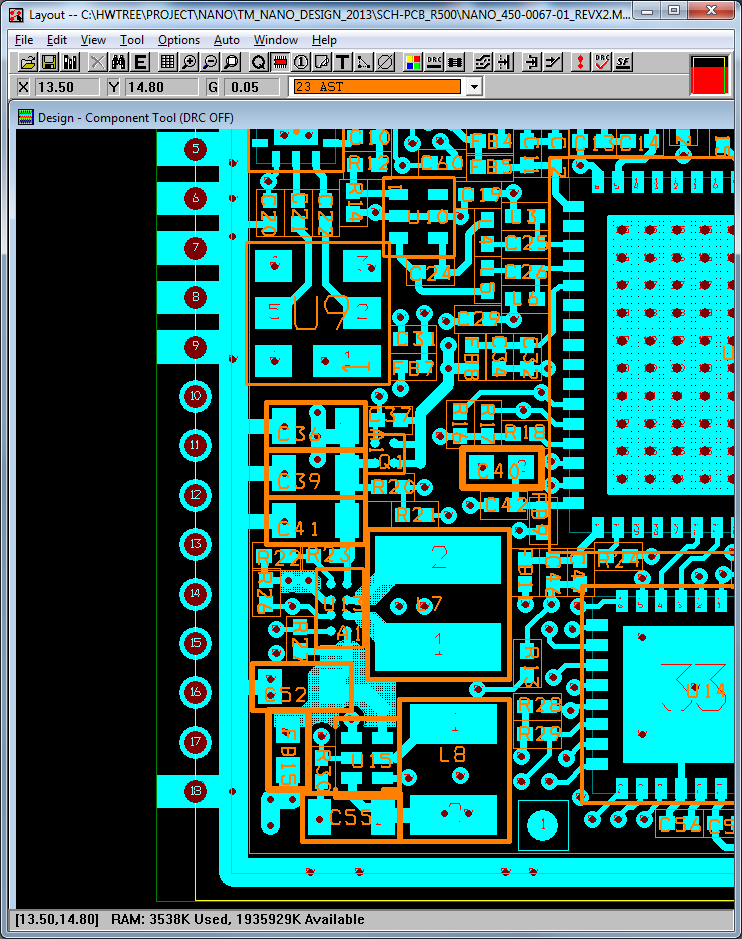

I ask these questions because I have a product in production using the TPS63036. It starts up in low current power saving mode. Great. I then operate the circuit and increase the load current to above 500 mA. For noise concerns I need to be in PWM at that time. Some units are sill in power saving mode. Are the TPS63036's damaged or not? They still regulate, ramping up and down in the power saving mode. Forcing PS/SYN=High does cause PWM mode as expected, but that is a change for my production product. I don't want to ship product with a latent damage. I can't decide if I have damaged TPS63036s without definition of "forced inductor current" and a specified range for "about 100 mA".

Please advise.

Thanks,

John