Other Parts Discussed in Thread: LM5160, LM5160DNTFBKEVM, PMP10532, PMP

Hello,

I'm using an LM5160 for a two output isolated flybuck. It is converting from 10-40 Vin to 3.3 Vout for all outputs (the isolated and non isolated one). It is working very well, except for EMI which is not very good (out of class B). Even with filtering, is not easy to achieve low EMI in conducted emission (150 KHz - 30 MHz).

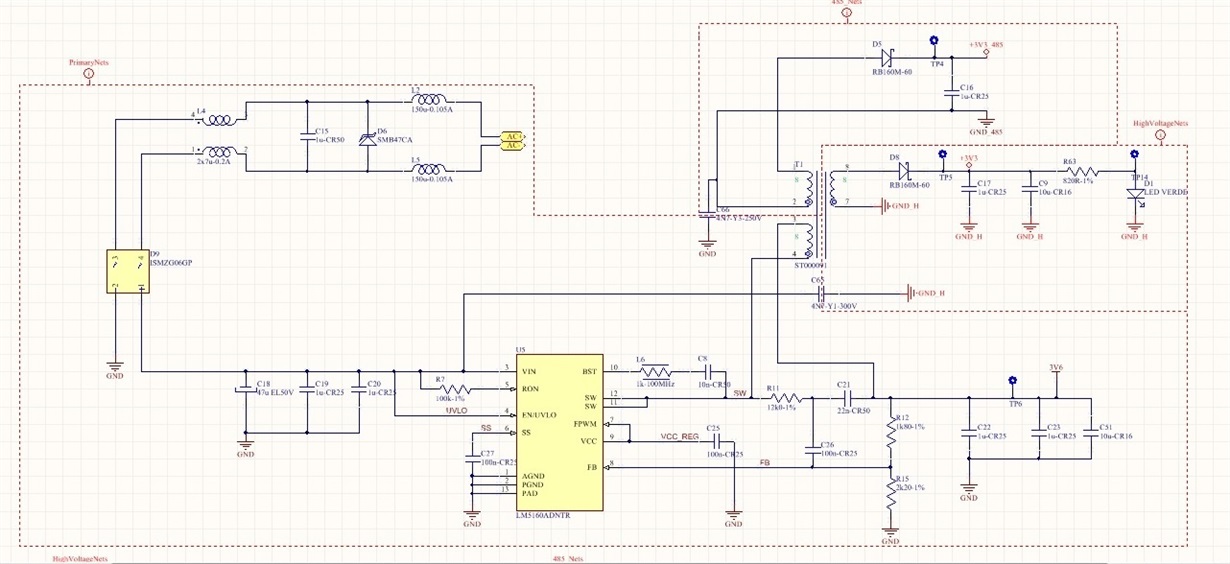

Here below my schematic, where transformer has an inductance of 8 uH.

Did you test the LM5160DNTFBKEVM for conducted emission? Is it possible to have their data? Do you have any idea on what to do to reduce emi?

Thank you,

Mattia Berton