Other Parts Discussed in Thread: LM5118, LM5170, LM5170-Q1

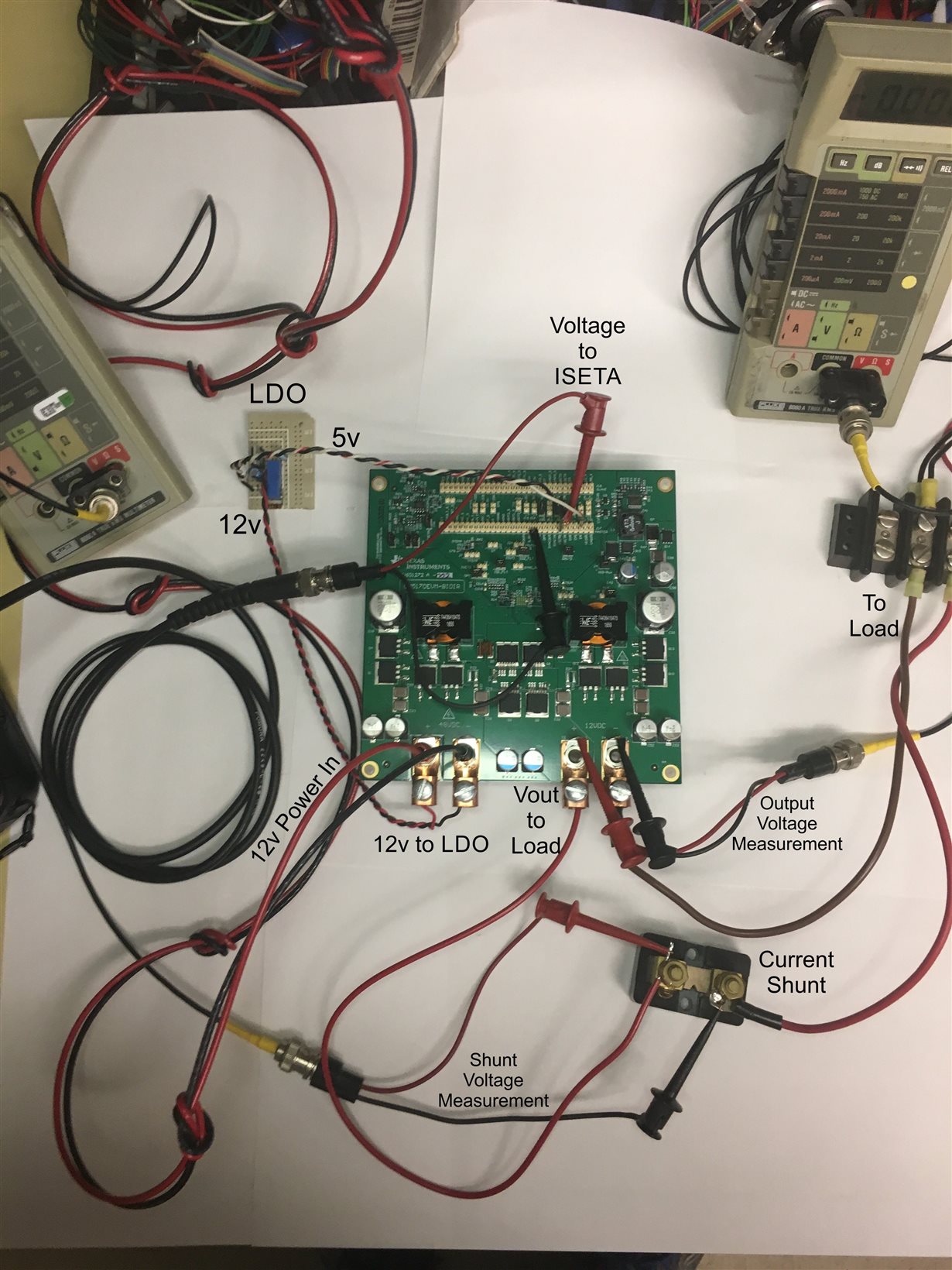

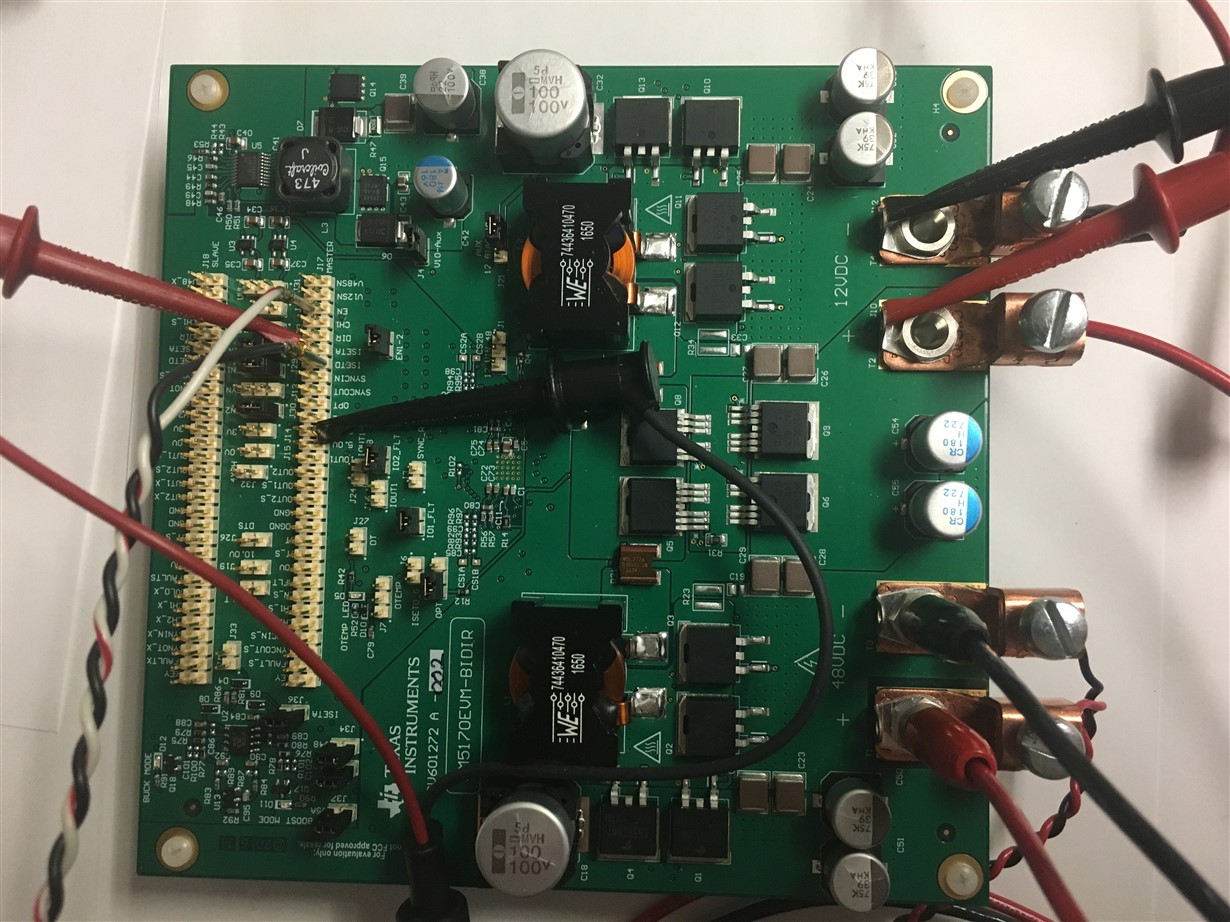

I have a low volume (test apparatus) project that the LM5170EVM-BIDIR will fit perfectly if I can configure it to do the following:

1) Self-start upon the application of primary (input) power.

2) Input voltage could range from 10v to 16v

3) Operate in the "Buck Mode" only

4) Allow the output voltage level to be controlled via an analog signal source (potentiometer or other voltage source)

5) The output voltage would be varied, set, and regulated and could vary from 95% to 60% of the input voltage (Again, Buck Mode Only)

6) Operate in the 2 phase mode with the option of the stacking to a 4 phase mode depending upon the power level needed for the application

7) ...

I have developed, designed, and fabricated this type of apparatus using another manufacturer's Buck/Boost converter EVM and found that unit to be far more complicated than is desirable. Especially regarding what mist be done for the startup sequence upon power up. I'm hopeful that the LM5170EVM-BIDIR will be much simpler in this regard and the scalability of this converter (through stacking) will offer some serious benefits also.

Many thanks for your time and consideration!

Dan Hagan