Other Parts Discussed in Thread: CC1310, , BQSTUDIO, EV2400, BQ34Z100EVM, GPCCHEM, GPCRB

Tool/software: TI-RTOS

Hello,

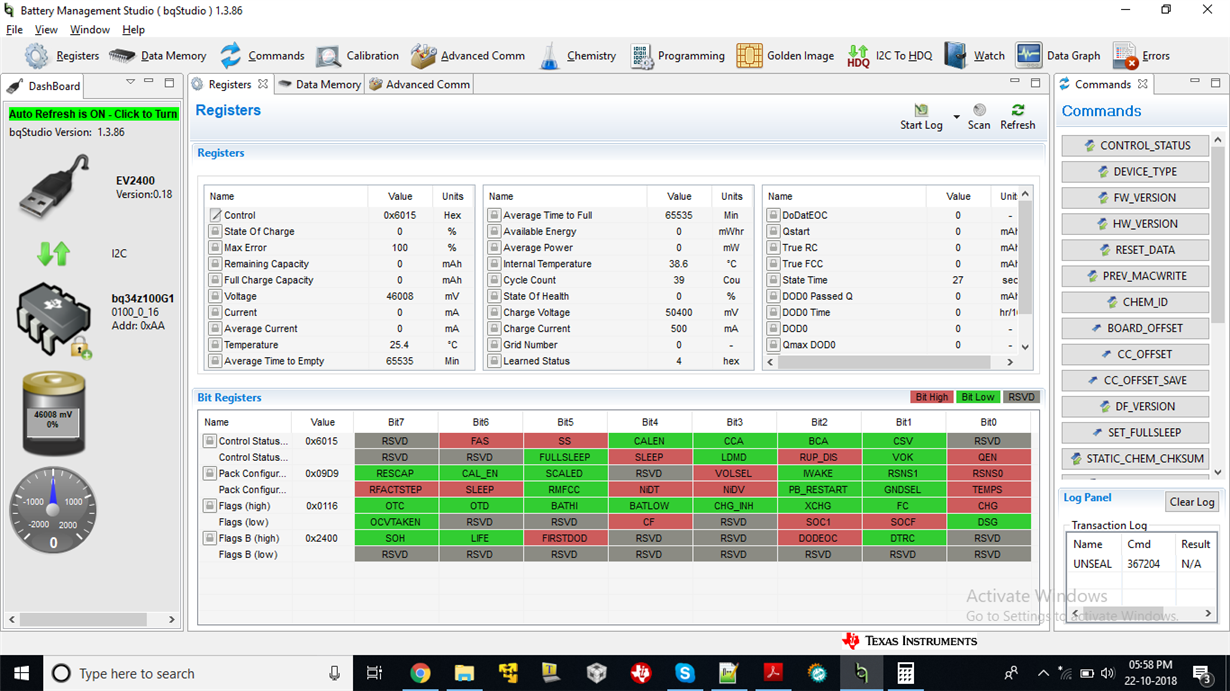

I'm using CC1310 with BQ34Z100-G1 for Battery monitoring application. I need help in programming side to read data such as Voltage, SOC, current, etc.

I'm attaching my schematic. Application is for 48V(12Vx4) Li-Ion battery.

Can I get reference code for the same?

Thank You

Viraj