Hello,

I resolved "Da" and "Db" problem choosing a TO-263 (D2PAK) fast switching diode, capable of carrying out the heat.

I have some remaining question to ask:

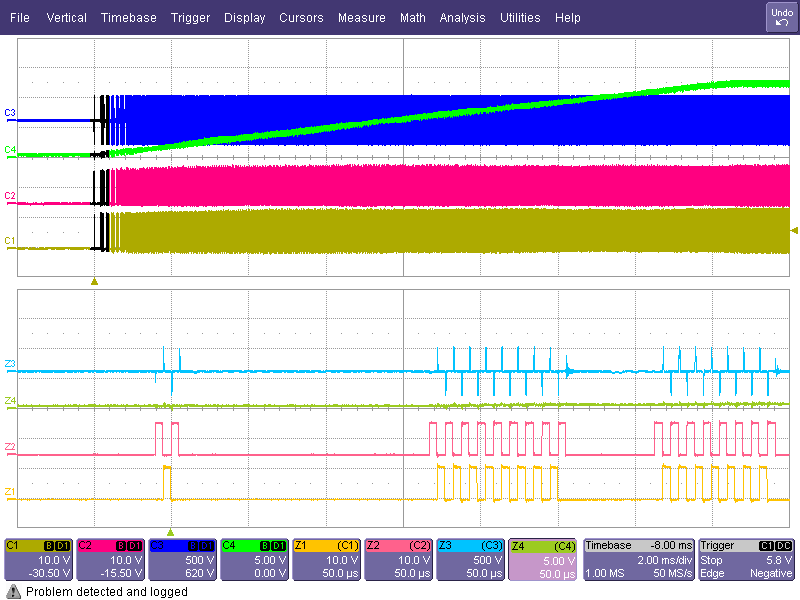

1) How do I set an optimum a compensation ramp with a primary current wave like this (the yellow trace which is descending instead of rising like in literature)? Has your colleague an idea about this?

2)I ask the first question because testing with an electronic load i have some point in wich the duty cycle of the controller change rapidly (instability points?), anyway mantaining the regulation of the output voltage like this:

3)How do I ptimize EMI for burst mode? I have some devices capting noise during burst mode at light load. Is increasing the minimum pulse time a good point to start? Any other suggestion?

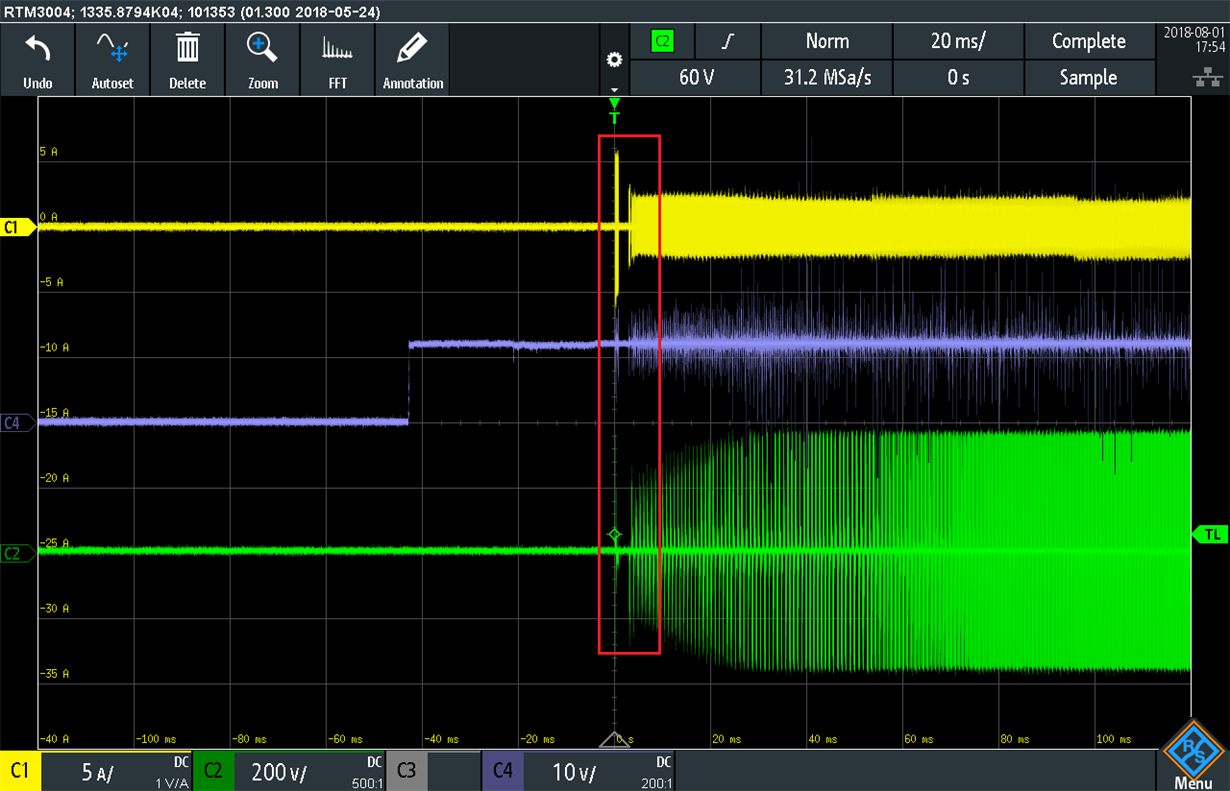

4) This is the "soft start" process: can you confirm that is all right? I have suspects regarding the first train of pulses (yellow primary current, violet controller 12V supply, green primary voltage)

zooming the red rectangle the current is higher than current limit set, having some pulses at 100% duty cycle:

Thanks and regards

Francesco