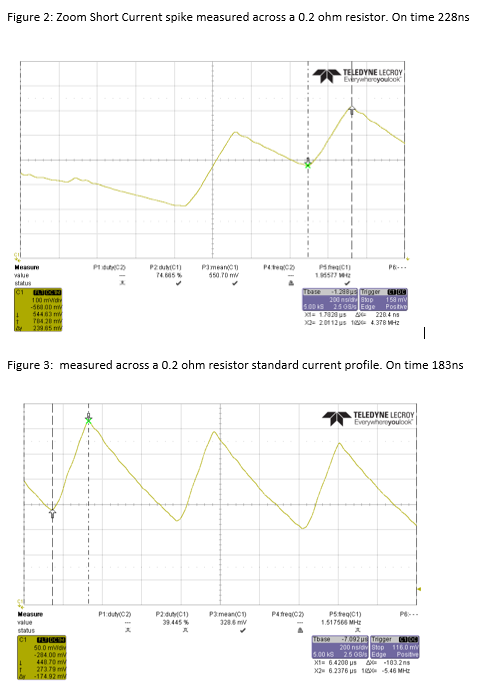

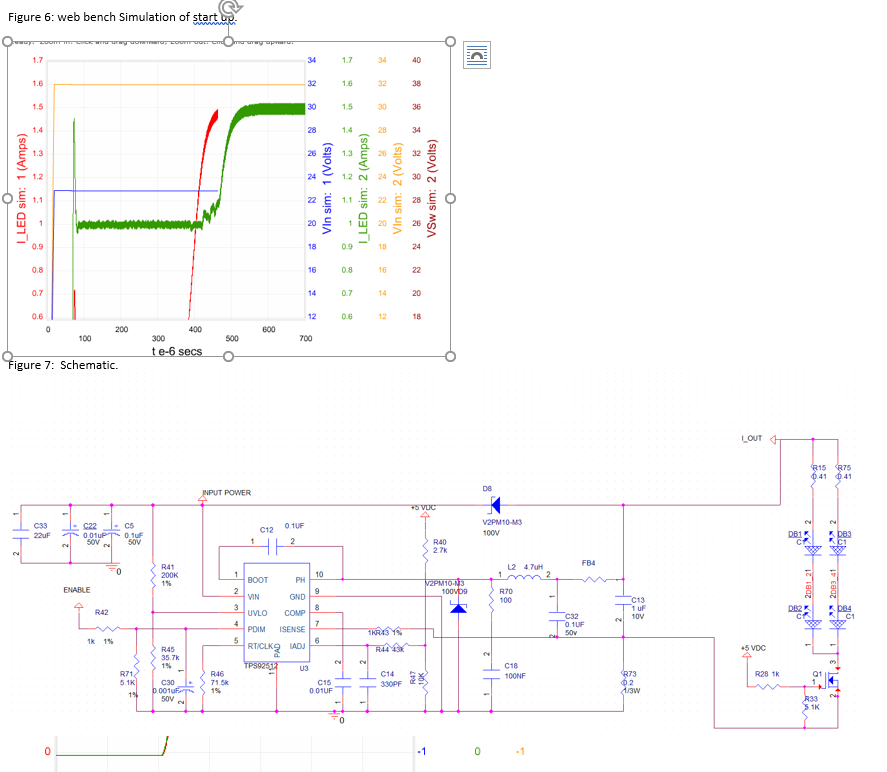

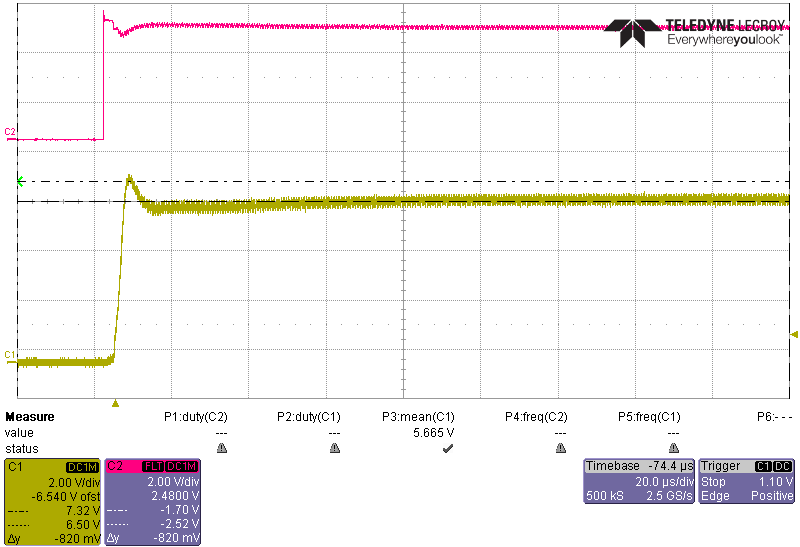

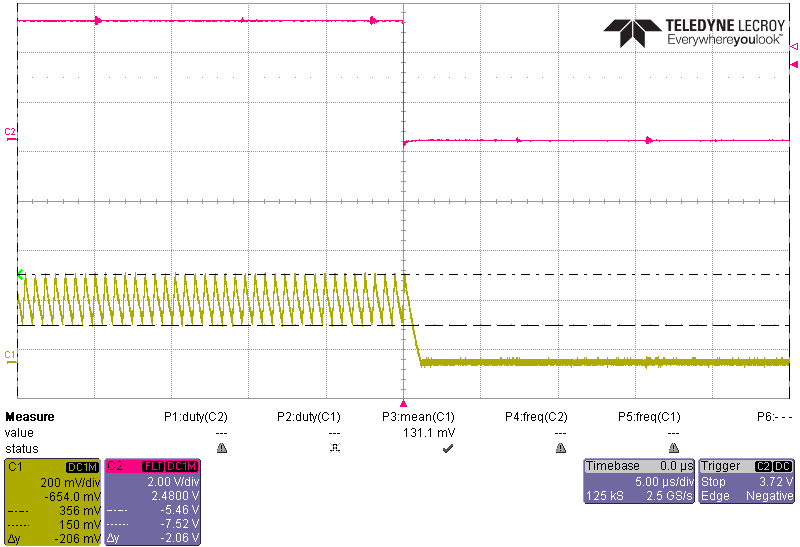

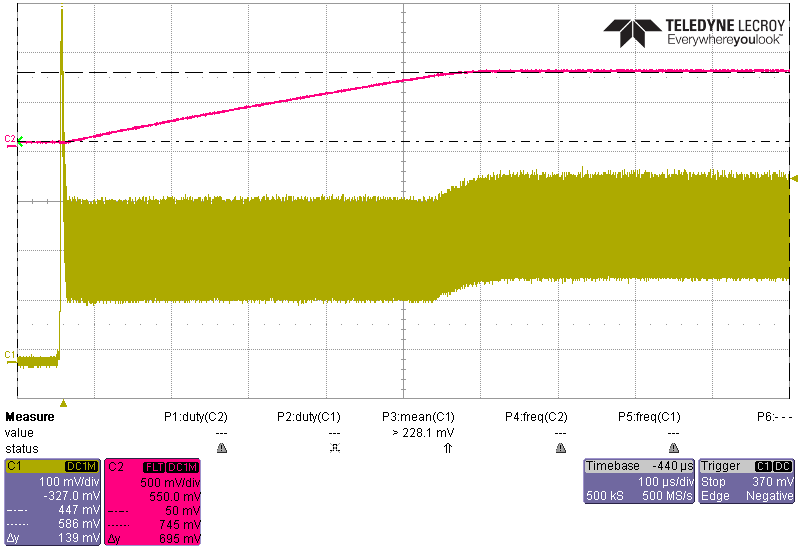

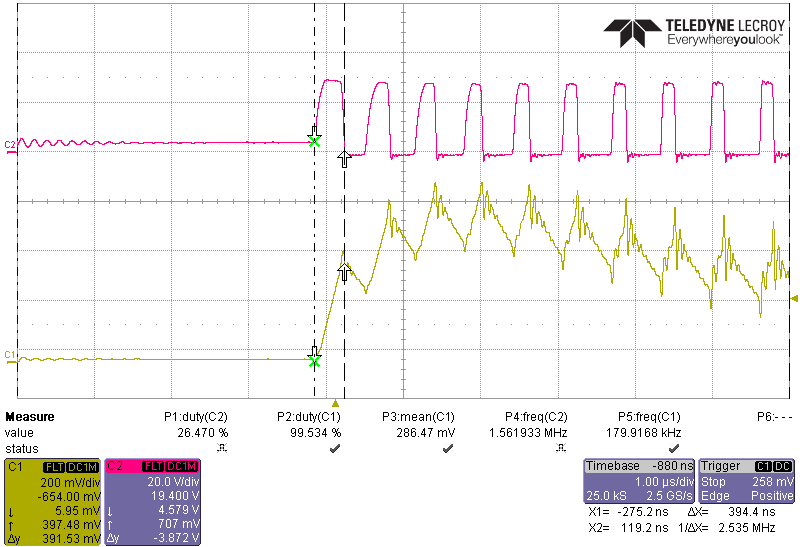

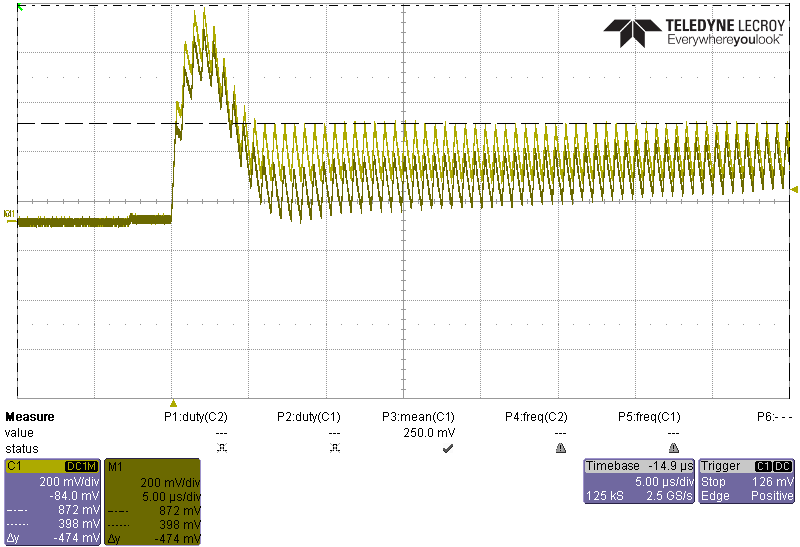

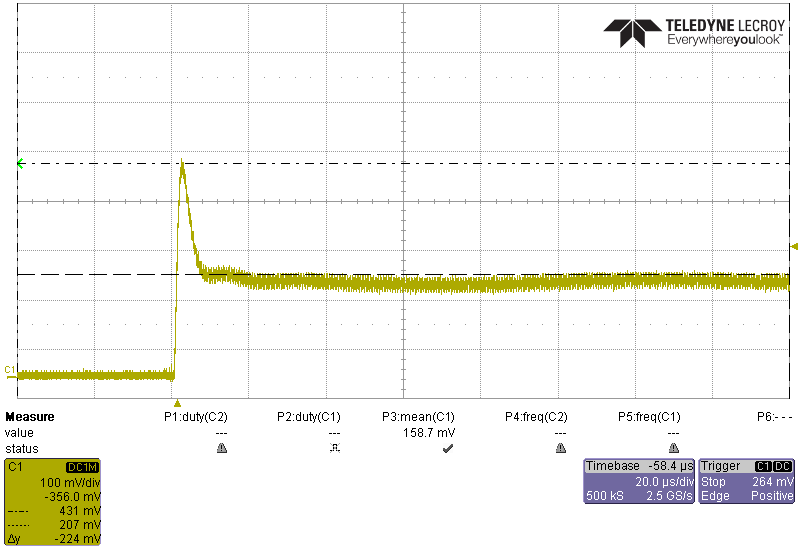

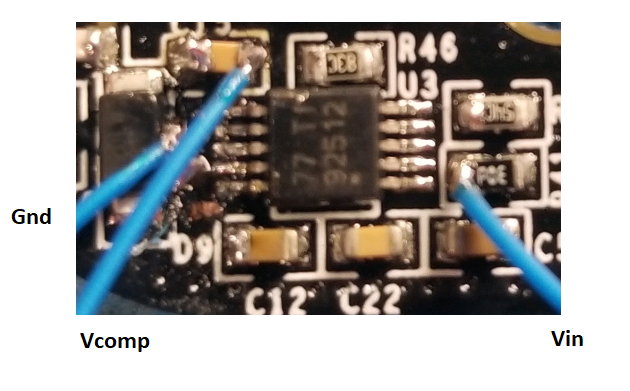

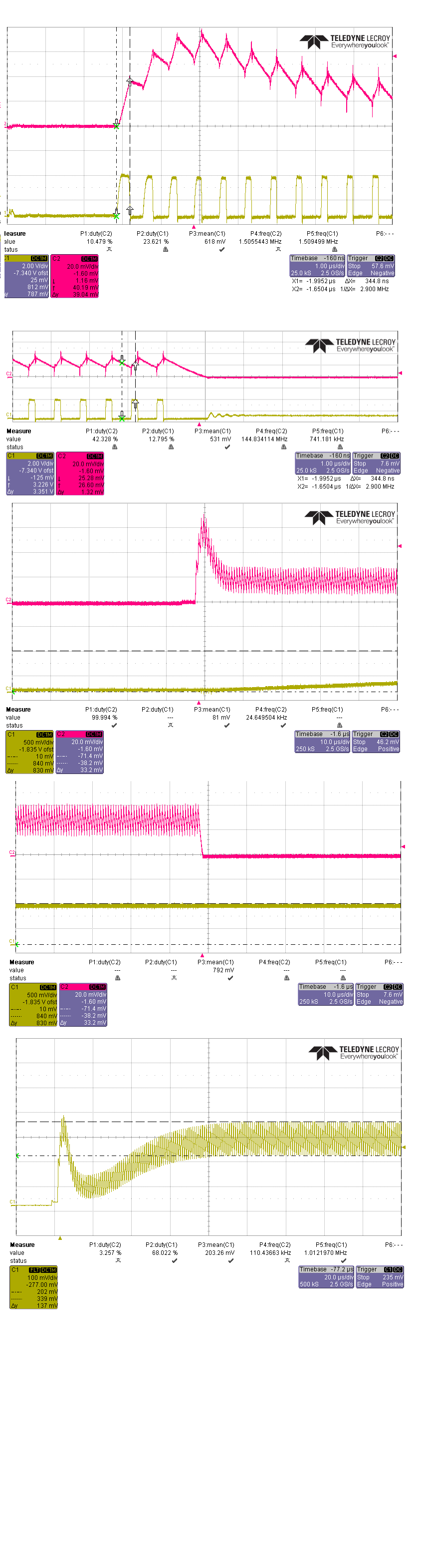

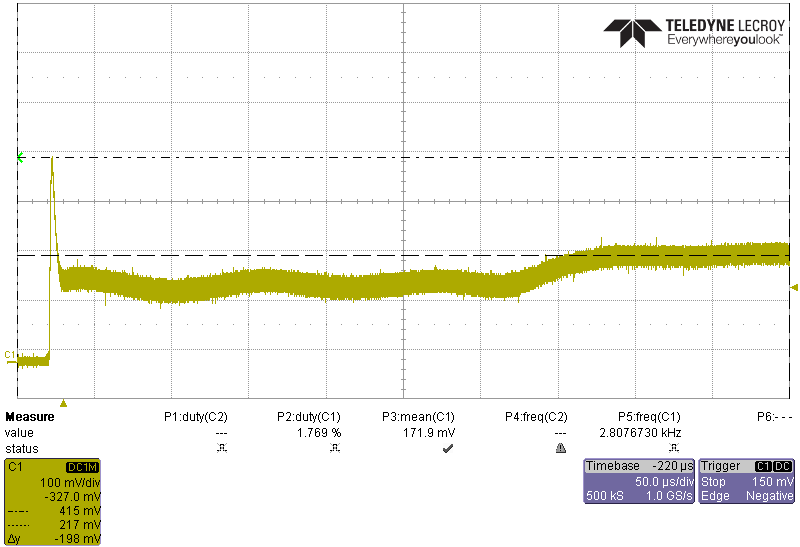

I am noticing a significant spike when ever PWM pin is enabled from the disabled state as shown below in figure 1 at upper input voltages around 30vdc. Web bench does not show this anomaly when simulating PWM however the PWM is much faster in the simulation. Web bench does show a similar spike in simulation ( figure 6) for the startup conditions which occurs while the comp capacitor charges but this spike is much smaller in than I measure in the simulation. If I calculate the value of Ipeak which can occur at start up I get 2.8A @ 30v, which is also lower than I am measuring in figure 2. As seen in figure 1 Vcomp is dis-charged so this would make sense that the system is going into minimum pulse width mode. Note the on time during the spike is larger than the on time in normal operation in figure 3 & figure 4. I would have expected it to be = Ton min 140nS. It seems to be worse when Vcomp only partially discharges than when it fully discharges. Any thoughts on why that may be or how to resolve the issue?

Figure 1: Yellow: Short Current spike measured across a 0.2 ohm resistor. Pink: Vcomp pin

Figure 2: Zoom Short Current spike measured across a 0.2 ohm resistor. On time 228ns

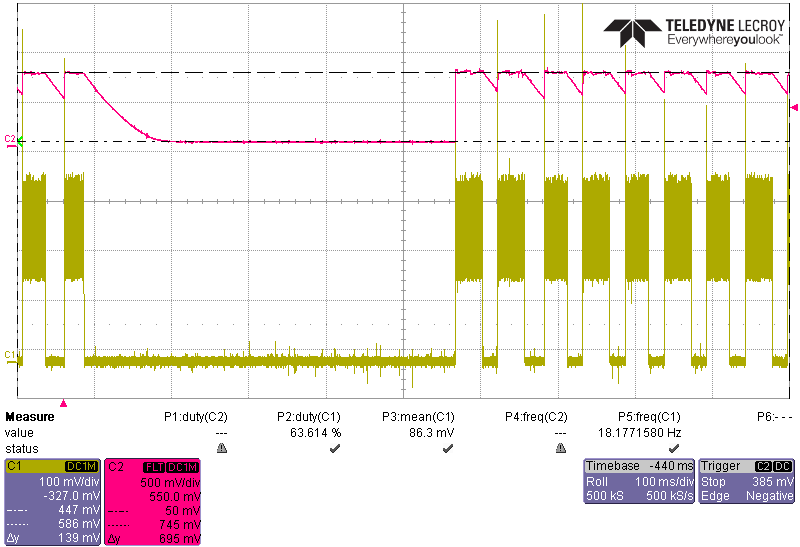

Figure 3: measured across a 0.2 ohm resistor standard current profile. On time 183ns

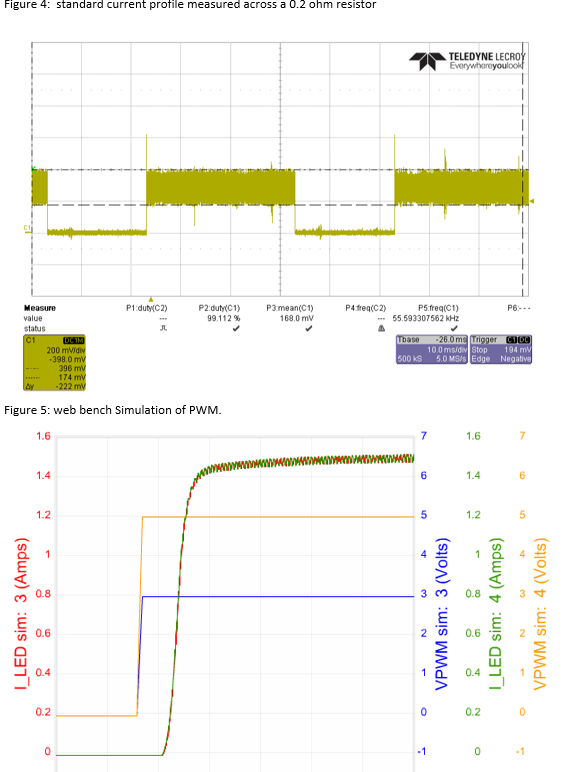

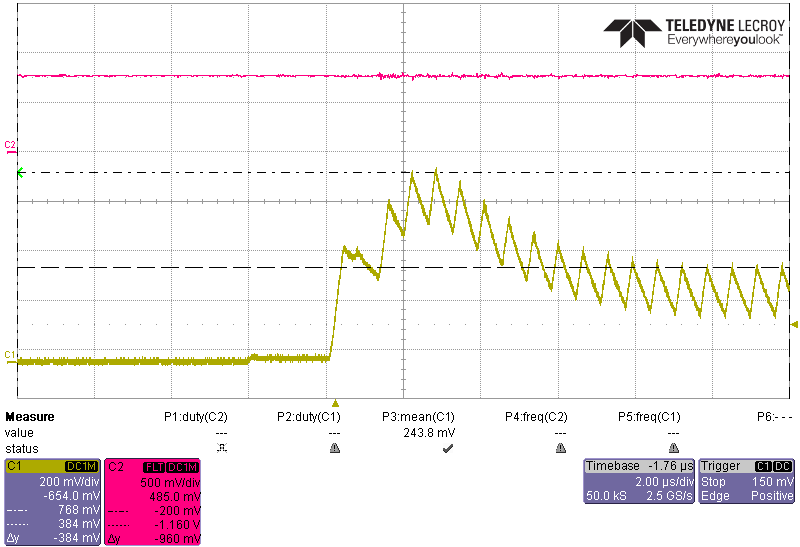

Figure 4: standard current profile measured across a 0.2 ohm resistor

Figure 5: web bench Simulation of PWM.

Figure 6: web bench Simulation of start up.

Figure 7: Schematic.