Hello,

We are facing similar situation.

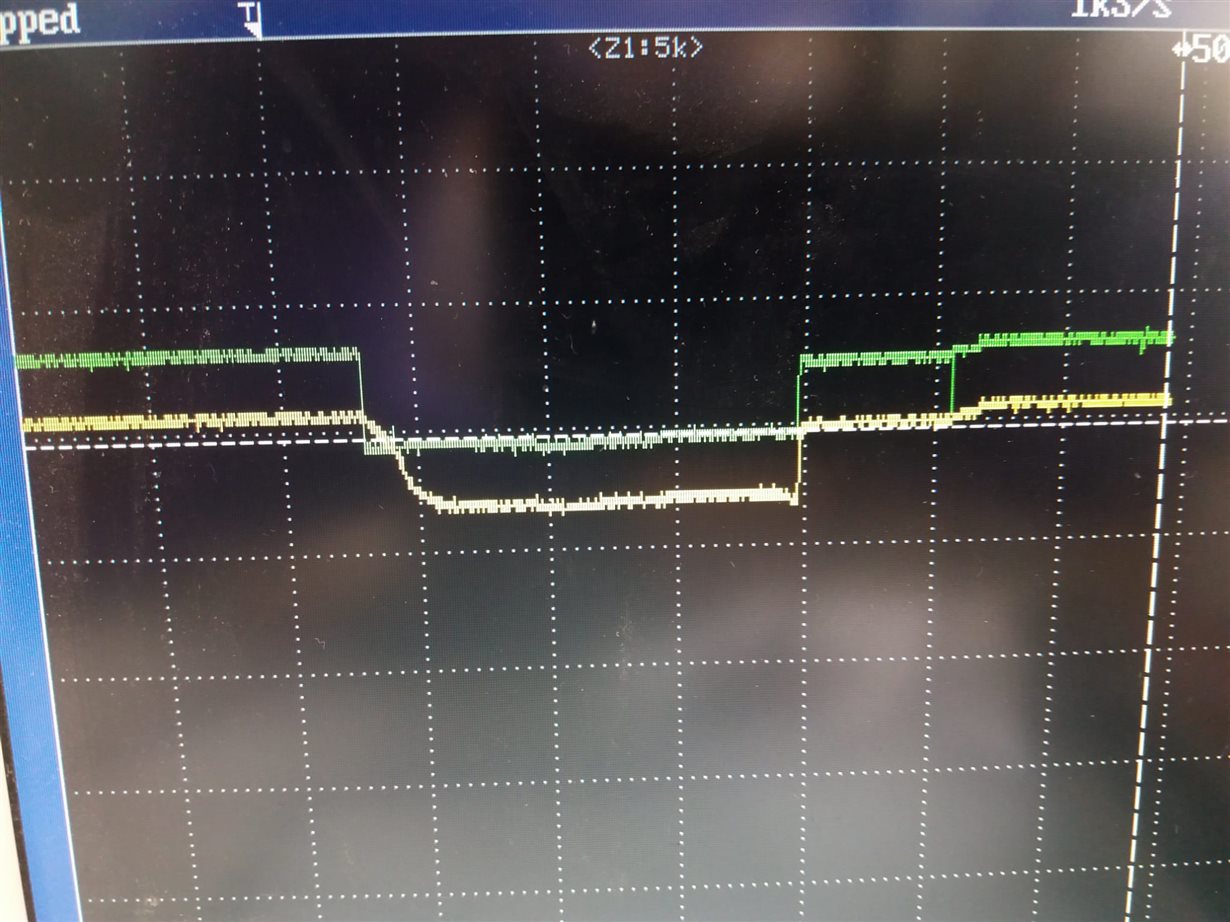

Vsel was connected to Vin (design error), powered by batteries higher than 6V and some devices are damaged.

Would be possible to share the squematic internally and go deeper on the severity of this problem?

Thanks in advance.

BRs,