We have implemented BQ24630 to charge 14.2V 3AHr LiFePO4 battery at Ichrg: 1.5A down to Iterm 150mA.

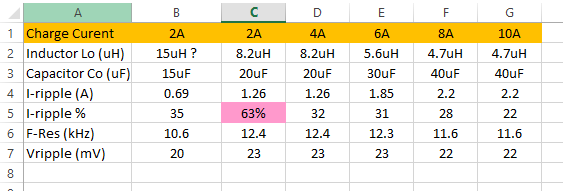

Recommended LC or 8.3uH / 20uF gives a large Ripple current of 1.25A, which is 83% of Iload, much higher than the recommended range in your datasheet of 20-40%

It also is creating unnecessary noise in our delicate circuit (shielded Inductor may help)

It also switches to DCM below 600mA and we have had instability at 150mA.

Can we change LC to 22uH / 8uF or 33uH / 4.7uF - both of these have resonant frequencies within the required 10-15kHz band.