Other Parts Discussed in Thread: BQSTUDIO, , GPCCHEM, GPCRB

Hello,

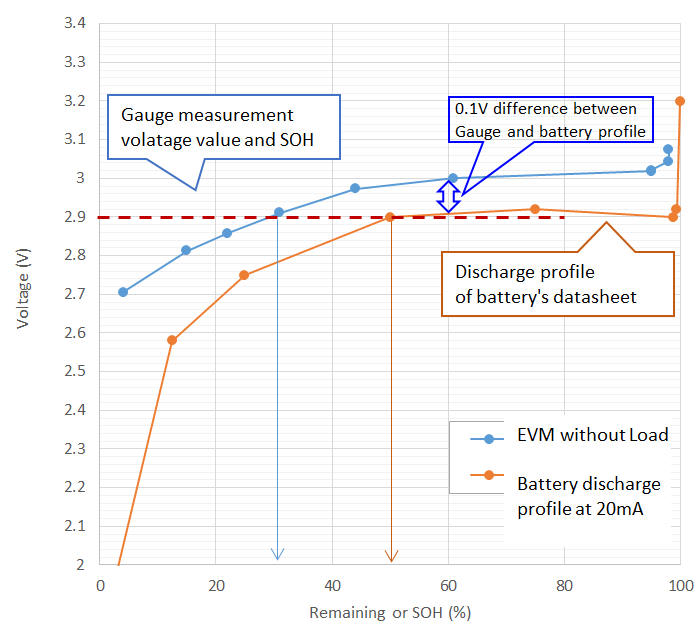

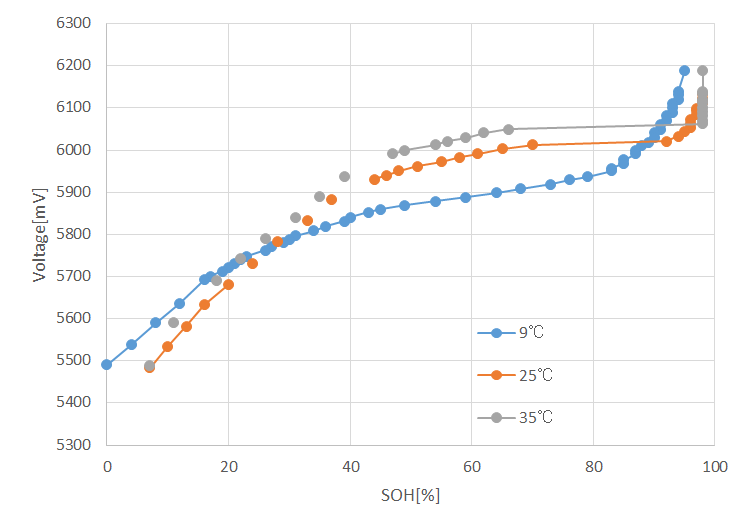

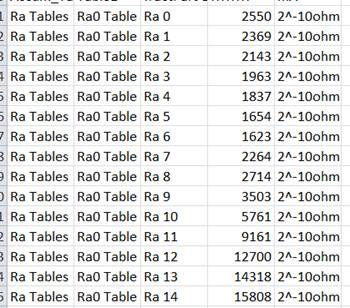

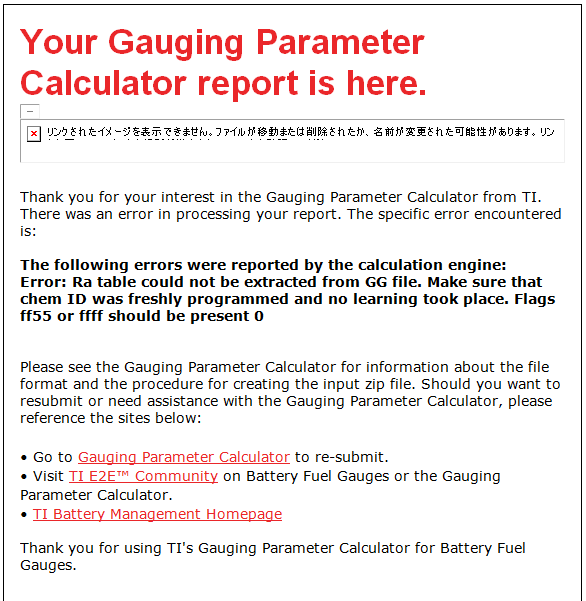

My customer is evaluating the SOH mode with LiMnO2 battery on EVM. But SOH seems incorrect as below.

- SOH decreases always 2% every GE toggling even though supply voltage was not changed.

- Voltage and temperature looks correct value.

Test result and EVM setting are summarized here:/cfs-file/__key/communityserver-discussions-components-files/196/NEC-BQ35100-evaluation_5F00_20200806.xlsx

this is including capture image of register, data memory of BQStudio.

Please check the result and give your advise to the customer?

Best regards,

Katsu