I have been very unlucky trying to get LMZM23601V5 to work on a modular power supply for a datalogger.

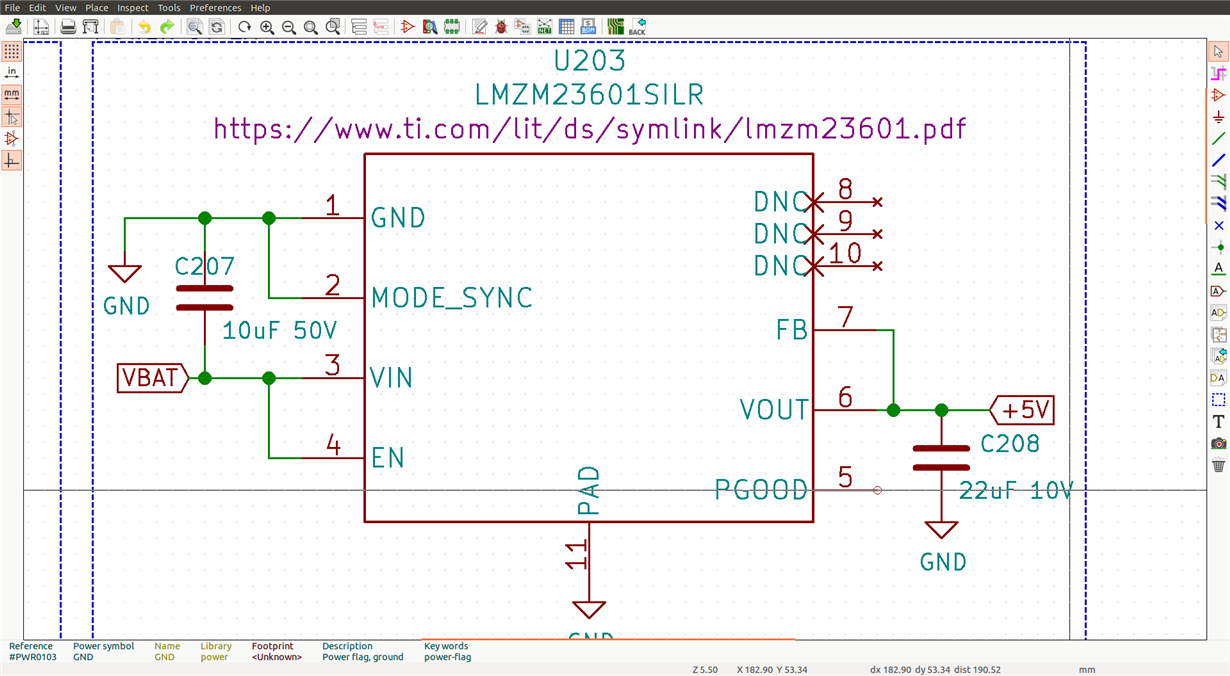

The best I could get so far were two units with Vout=Vin. One was reflowed in a controlled temperature oven and the other was soldered by hand with hot air. The only components on the PCB are the LMZM23601V5 and the input (10uF) and output (22uF) capacitors.

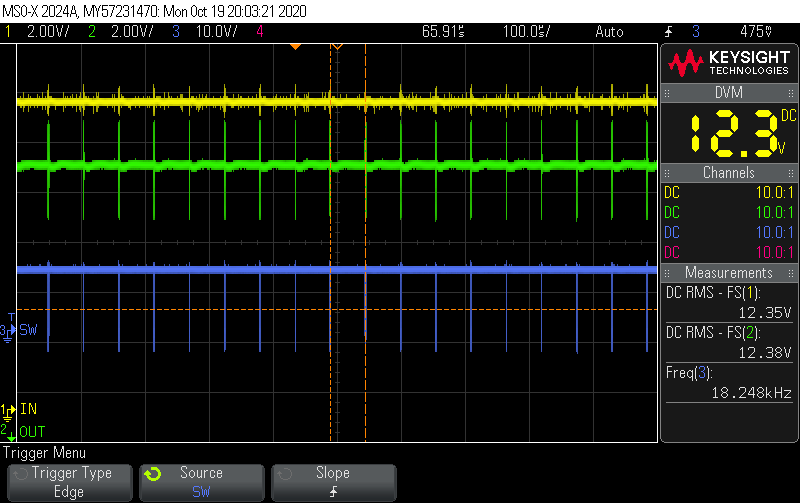

Vin is 12.35V. Vout is 12.34V.

There are no shorts to ground that I can find. Current is 0.0A.

Switching frequency at SW is around 15kHz on one unit and 18kHz on the other.

Vin and Vout are stable and both LMZM23601 are cool to the touch.

Adding a 1k load on the output does not change Vout.

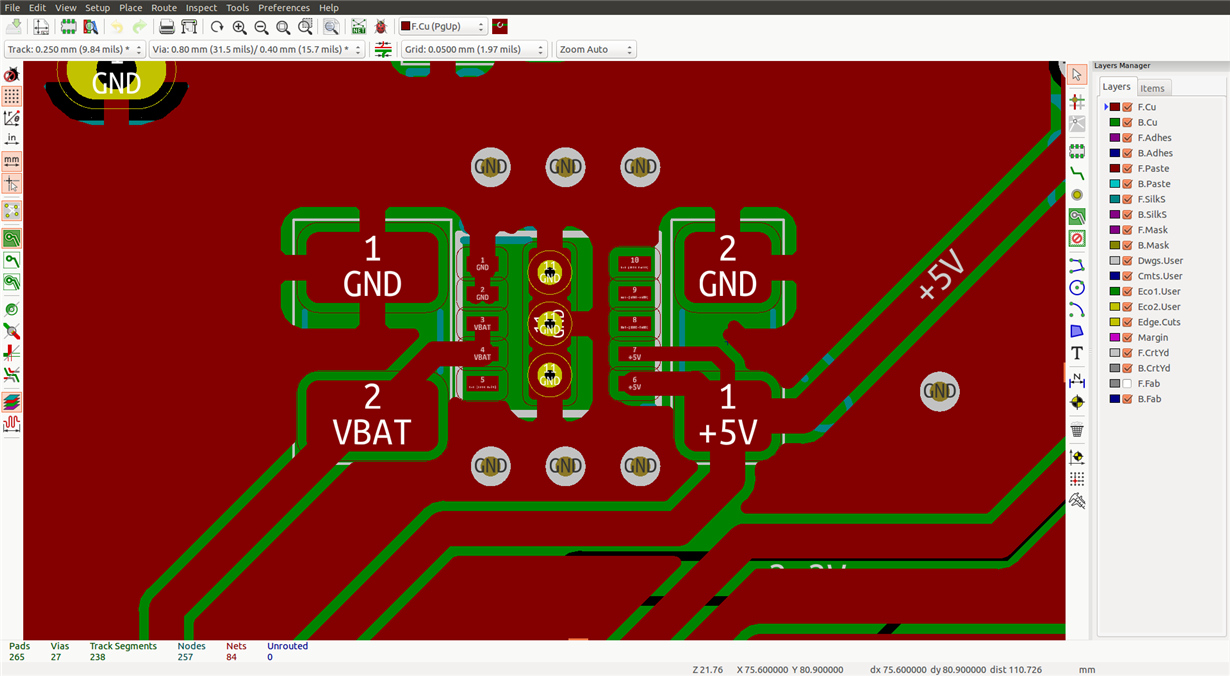

Pad11 is connected to ground and has enough copper for heatsinking.

PCB layout. PG is not connected.

Relevant part of the schematic

Yellow=Vin / Green=Vout / Blue=SW frequency

What am I doing wrong here?