Other Parts Discussed in Thread: TPS7A45

1. When the EN pin is not used for switch control, there are two ways to connect the EN pin,One is directly connected to VCC, the other is connected to EN after two 10k resistors are divided;

Under the normal working condition of chip reverse current protection, which connection method is more reasonable?

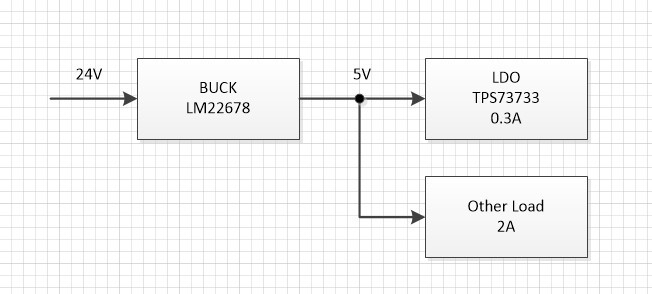

2. Does TPS73733 have a minimum load requirement?