Other Parts Discussed in Thread: LM5176, MSP430FR5972, CSD16321Q5, CSD18563Q5A, LM25122-Q1, LM5122ZA,

Tool/software: WEBENCH® Design Tools

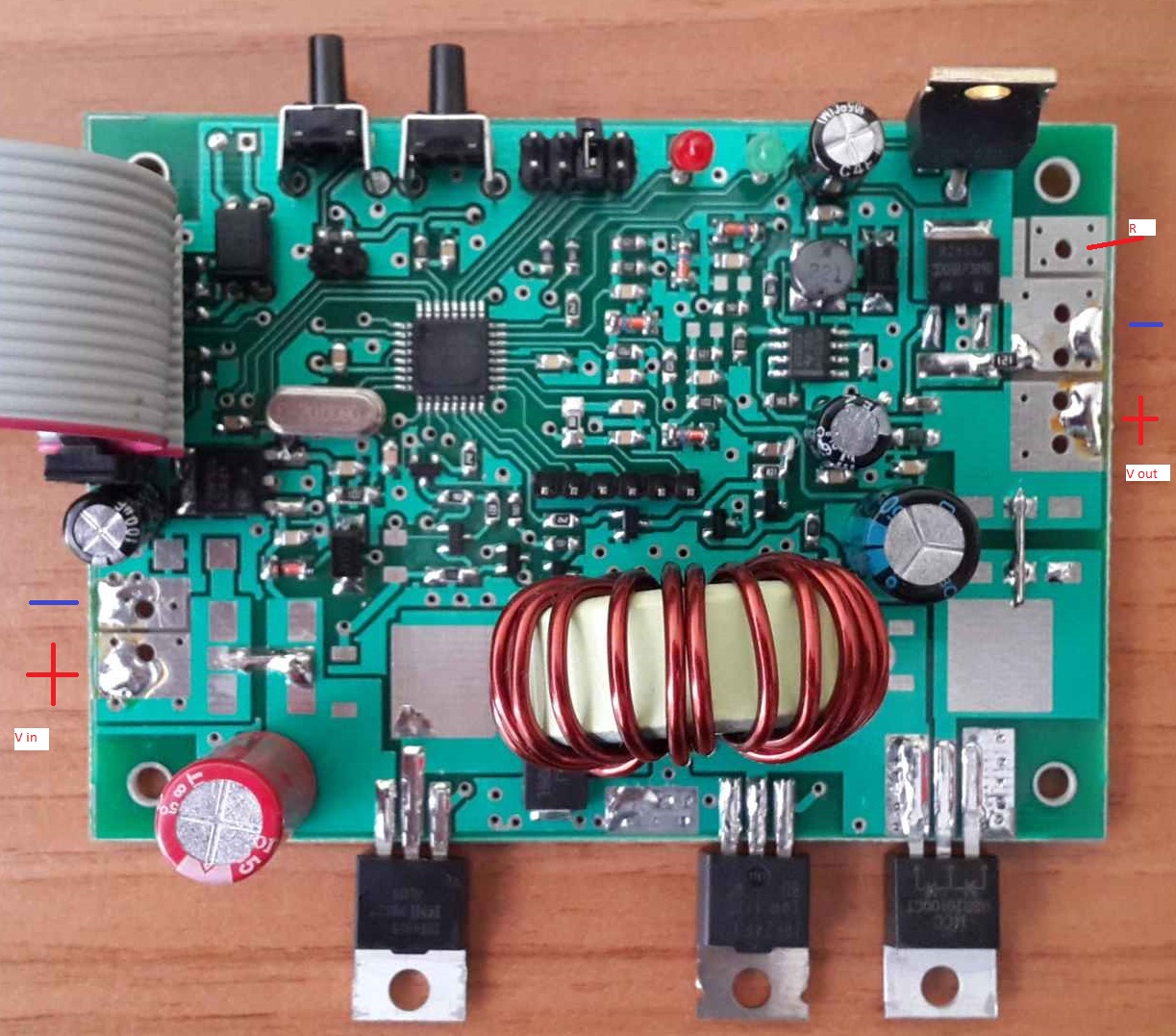

I can't start the circuit ...

No generation.

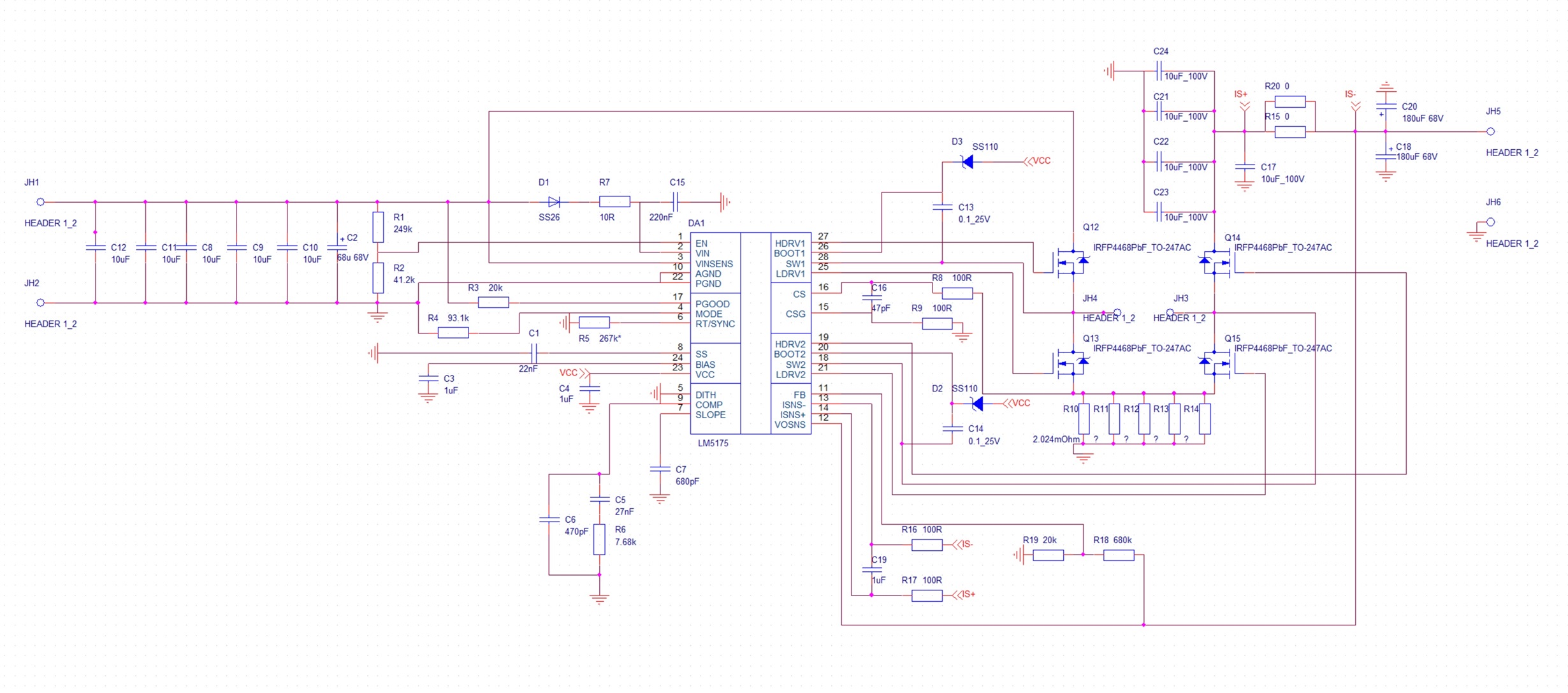

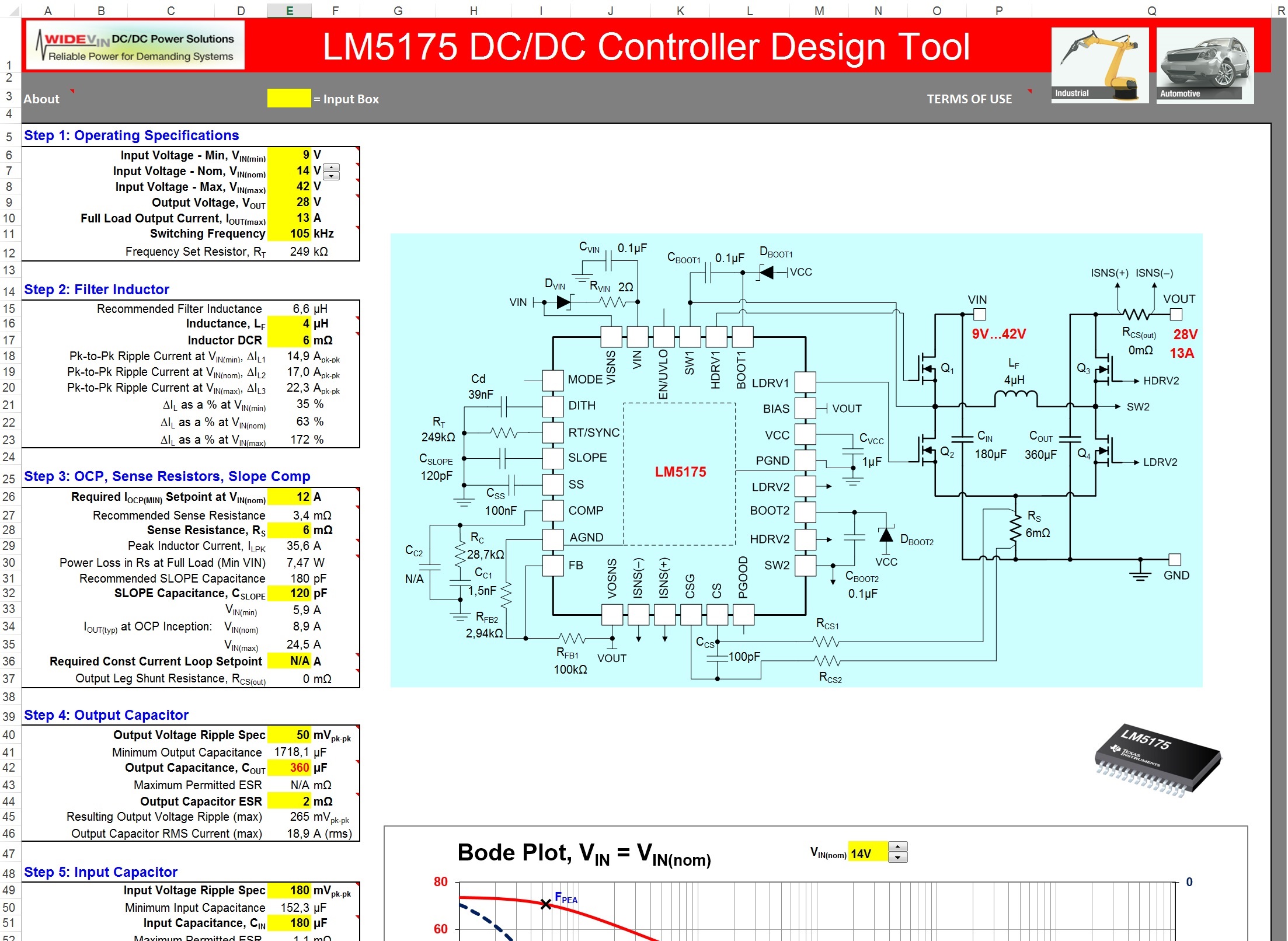

the scheme that Webench squeezed out to me is complete nonsense, does not correspond to the scheme that the "initial installation" of Excel tables from TexasInstruments does.

See attachment.

What to do ?

Please, Just don't advise me to use Webbench!

I am interested in the answer from real people who made power supplies on LM5175

What is my mistake?