Other Parts Discussed in Thread: GPCRA0, GPCRB, BQSTUDIO

Hello,

I need help. I did tests but after upload, I got failed results.

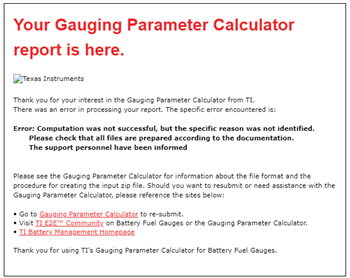

GPCRA0 - failed (check screenshot) and zip file with raw data GRCRA0_2.zip

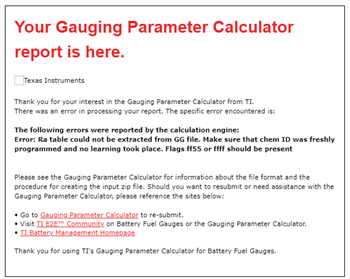

GPCRB - failed (check screenshot) and zip file with raw data GPCRB_3.zip

And also BQ2741-G1B doesn't have this flag "Flags ff55 or ffff should be present"

What did I wrong?

Best regards,

Michael