Hello,

I need to change the VADJ voltage on a ZC706 Xilinx evaluation board. I found quite a few tutorials for that and it seemed to fit my needs. (https://www.xilinx.com/support/answers/56811.html and https://www.xilinx.com/support/answers/53599.html). They consist essentially in scripts that can be loaded in the TI Digital Power Manufacturing tool to reprogram the UCD90120A in charge of the power rail I want to adjust.

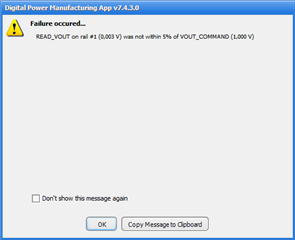

However, following carefully the procedure I failed to change VADJ on the target, no matter what version of the script I pick for that (1.8V, 2.5V [default] or 3.3V). The TI Digital Power Manufacturing tool stops at some point during programming and reads the following:

| ON_OFF_CONFIG write Mode: OPERATION Only [0x18] on UCD90120A @ PMBus Address 101d error: WRITE VERIFICATION READ BACK FAILED; can not continue with project import |

Before that, there were 3 read attempts on this very register:

| SAA: ReadByte (Address 101d, Cmd 0x02) error: NACK |

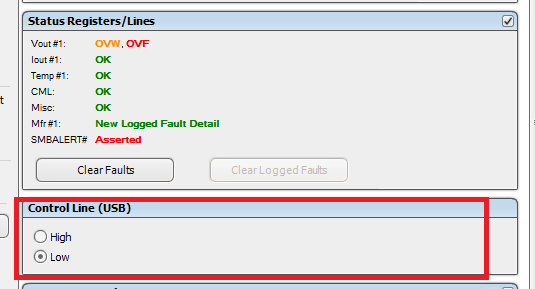

I don't quite understand what's going on; it seems that some register fails to be read? What could prevent this specific register from being read? some timing issue making the device stuck?

I used the USB to GPIO adapter from TI for the device programming and its firmware is up to date. I can read the device ID so the UCD90120A seems to be alive.

Hopefully the board is still working fine; the rail I wanted to adjust reads the same voltage though (so nothing seems to have been programmed)

Regards,

Quentin