Other Parts Discussed in Thread: TPS544B25, TIDA-01393, TPS650861, TPS548B22, CSD87331Q3D, CSD87381P

For one of our MPSOC (XCZU6CG) based design we have chosen to use TPS6508641

I have strictly followed the user guide and datasheet of TPS6508641

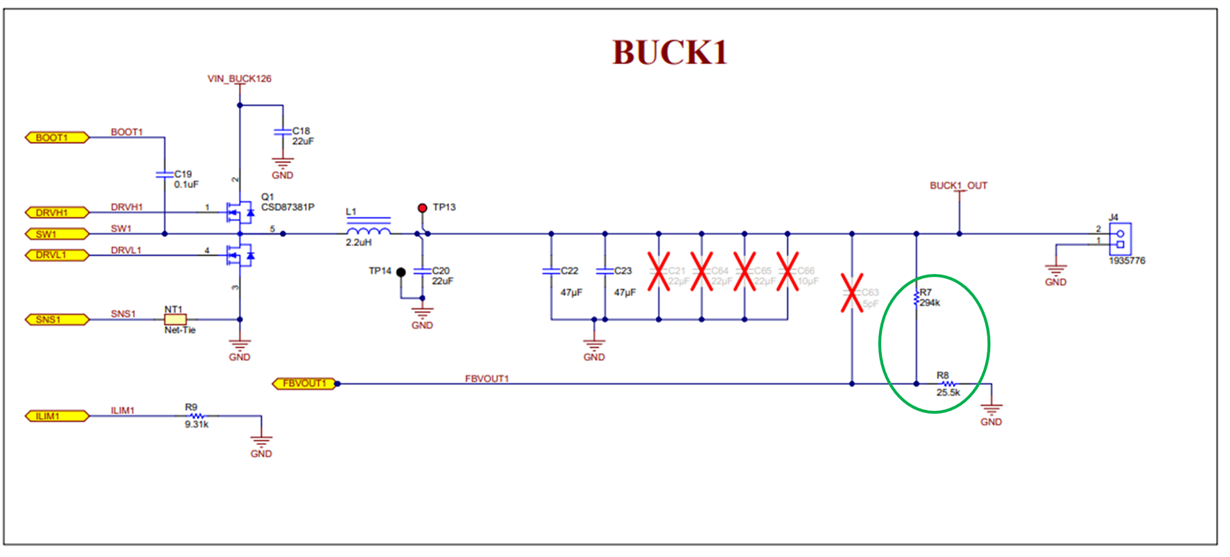

Posted are the Schematic of TPS6508641, for which the timing diagram is also attached

Power_Sequence_MPSOC_XCZU6CG.pdf

SCHEMATIC_PMIC_MPSOC_XCZU6CG.pdf

Kindly let us know whether the schematic will adhere to the timing sequence or not