Hi Team,

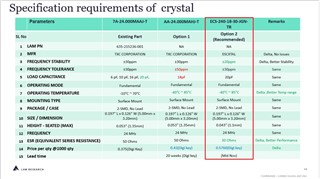

A customer is currently using AM3358BZCZ100 for which i am using a Crystal of 24Mhz

since the crystal is in EOL the alternative parts available are having higher tolerances than mentioned in the Spec sheet ,

I want to understand how will it affect the board.

Frequency tolerance and frequency stability

i would also like to understand ,TI suggests to 24Mhz for AM3358BZCZ100 master clock with tolerance of + - 50PPM ,

If I am using a crystal which has a tolerance of +-100 PPM how will it affect the Performance of the Processor AM3358BZCZ100,

also can you suggest the tests i need to carry out once i change this 24MHz crystal to validate it for the processor AM3358BZCZ100

Thanks.

Regards,